Multifunctional building material and preparation method thereof

A technology of building materials and porous materials, applied in the field of building materials, can solve problems such as rising surface temperature of heat-insulating bricks, restrictions on the use of heat-insulating bricks, poor waterproof effect, etc., to achieve high cost performance, reduce weight, and improve heat resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

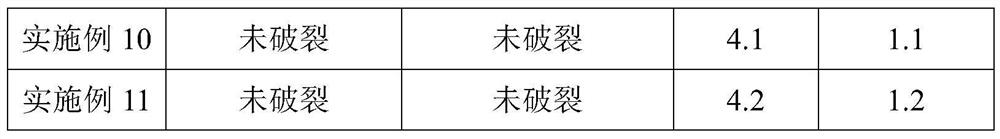

Examples

preparation example Construction

[0068] The second aspect of the present invention proposes a kind of preparation method of building material, comprises the following steps at least:

[0069] (1) Add inorganic gel material, lightweight porous material, inorganic powder, olefin polymer, ethylene-vinyl acetate copolymer, acrylic acid polymer emulsion, and polyurethane emulsion into a stirring container, and mix well;

[0070] (2) The mixture obtained in step (1) is injected into the mold after being coated with a release agent, and pressurized;

[0071] (3) Drying the modules obtained after press molding and demolding to obtain the building material.

Embodiment 1

[0074] A multifunctional building material is provided, the raw materials are calculated by mass percentage, including 18% Portland cement a, 2% Portland cement b, 40% ceramsite, 4% kaolin, 1% heavy Calcium carbonate, 3.5% styrene-butadiene-styrene block copolymer, 6% ethylene-vinyl acetate copolymer, 18% acrylic polymer emulsion, 7% polyurethane emulsion, 0.5% mold release agent.

[0075] Also provided is a preparation method of a multifunctional building material, comprising the steps of:

[0076] (1) Portland cement a, Portland cement b, ceramsite, kaolin, heavy calcium carbonate, styrene-butadiene-styrene block copolymer, ethylene-vinyl acetate copolymer, acrylic acid polymer emulsion 1. Add the polyurethane emulsion into the mixing container and mix evenly;

[0077] (2) inject the mixture obtained in step (1) into the mold coated with the release agent, and pressurize it;

[0078] (3) drying the module obtained after press molding at 130° C., and demoulding to obtain th...

Embodiment 2

[0103] A multifunctional building material is provided, and the raw materials are calculated by mass percentage, including 25% of Portland cement a, 5% of Portland cement b, 32% of ceramsite, 2.4% of kaolin, and 0.6% of heavy Calcium carbonate, 2% styrene-butadiene-styrene block copolymer, 4.5% ethylene-vinyl acetate copolymer, 20% acrylic polymer emulsion, 8% polyurethane emulsion, 0.5% mold release agent.

[0104] Also provided is a preparation method of a multifunctional building material, comprising the steps of:

[0105] (1) Portland cement a, Portland cement b, ceramsite, kaolin, heavy calcium carbonate, styrene-butadiene-styrene block copolymer, ethylene-vinyl acetate copolymer, acrylic acid polymer emulsion 1. Add the polyurethane emulsion into the mixing container and mix evenly;

[0106] (2) inject the mixture obtained in step (1) into the mold coated with the release agent, and pressurize it;

[0107] (3) drying the module obtained after press molding at 130° C., ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com