Preparation method of low-cost sulfuric-acid-corrosion-resistant 09CrCuSbRE hot-rolled round steel

A sulfuric acid-resistant, low-cost technology, applied in the field of material metallurgy, can solve the problems of difficult control, high manufacturing cost, and unsuitable high content of Ti element, and achieve the effect of reducing the quality of corrosion loss, reducing the percentage content, and reducing the corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

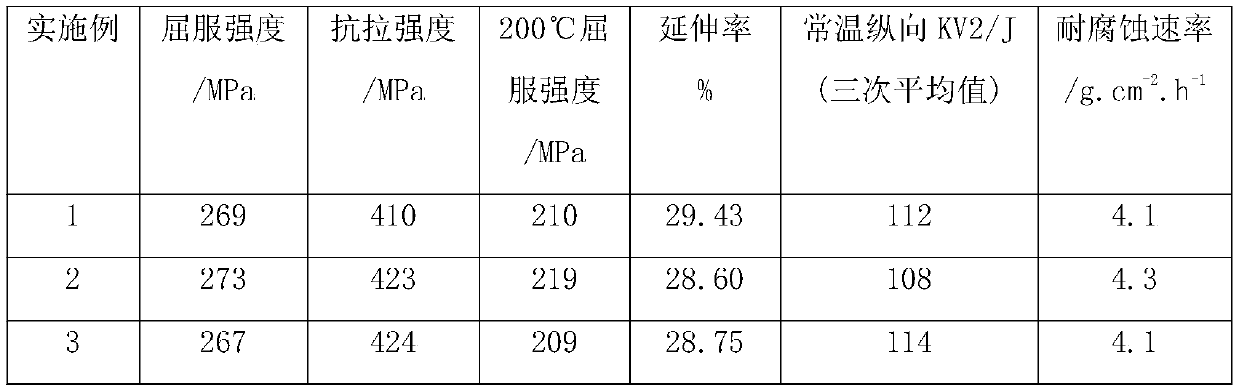

Examples

Embodiment Construction

[0030] The present invention will be further described through specific examples below, and the examples are only for the purpose of explanation, and the protection scope of the present invention is not limited to the examples.

[0031] A low-cost preparation method of sulfuric acid corrosion-resistant 09CrCuSbRE hot-rolled round steel, steelmaking process: converter-external refining-VD vacuum treatment-continuous casting, steel rolling process: billet heating-high-pressure water dephosphorization-Ф850mm blanking Machine—Ф700mm×3+Ф550mm×4 continuous rolling mill rolling—sawing (sampling)—slow cooling—nondestructive testing (ultrasonic testing + eddy current / infrared / magnetic leakage testing)—stacking (cooling, heat collection)——inspection - Grinding - bundling - storage - delivery; the technical parameters controlled in the rolling process are:

[0032] 1) Heating temperature 1150-1200 ℃, holding time ≥ 3 hours;

[0033] 2) The starting temperature of rolling is ≤1100℃;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com