Transverse drilling mechanical device for vertical columns of corrugated beam steel guardrail

A technology for guardrail columns and mechanical devices, which is applied to metal processing mechanical parts, boring/drilling, drilling/drilling equipment, etc. Quality, cost savings, improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

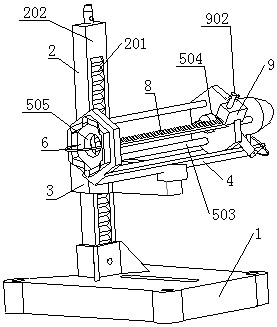

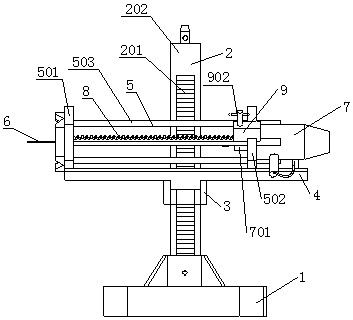

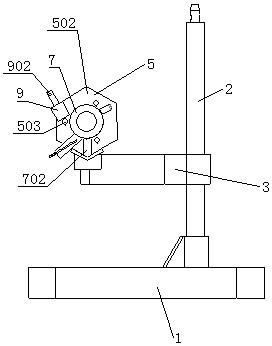

[0018] A horizontal opening mechanical device for a corrugated beam steel guardrail column, comprising a base 1, on which a lifting platform 2 is fixedly connected, and the lifting platform 2 is connected to a longitudinal pipeline lifter 3 capable of moving up and down on the lifting platform 2, A horizontal "V" shaped support 4 is fixedly connected to the vertical pipeline elevator 3, and a guide frame 5 is fixedly connected to the support 4. The guide frame 5 includes a fixed plate 501, a moving plate 502, and the fixed plate 501 A plurality of cylindrical guide rods 503 are connected between the moving disc 502, one end of the guide rods 503 is fixedly connected to the fixed disc 501, and the other end can move laterally on the guide rods 503 through the passage provided on the moving disc 502. hole, the fixed plate 501 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com