Method for processing dandelion fiber by electrostatic flocking

A technology for dandelion fiber and electrostatic flocking, which is applied in the field of fiber textiles, can solve the problems of lack of spinnability, dandelion fiber is not suitable for spinning processing, and cannot be spun, and achieves easy flocking, low processing cost, and convenient collection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

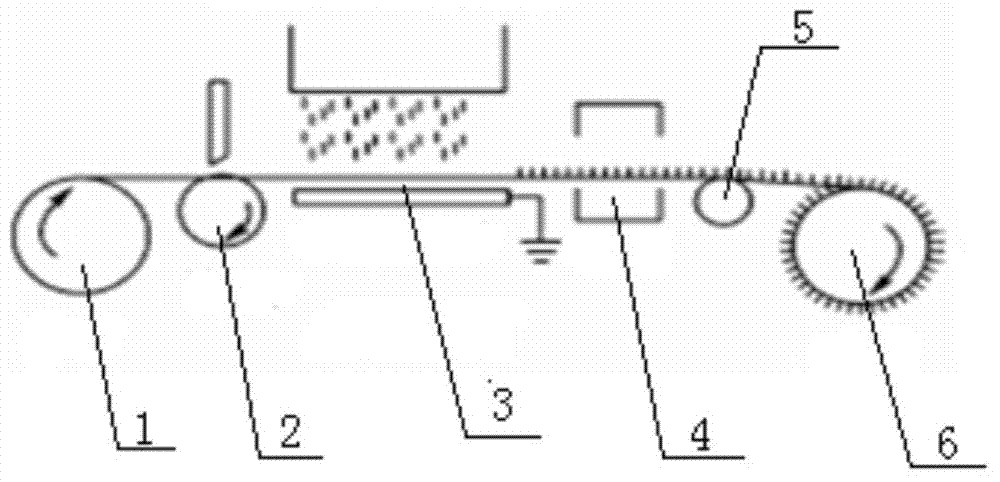

[0024] A method for processing dandelion fiber electrostatic flocking, comprising the following steps: feeding 1→scraping adhesive 2→electrostatic flocking 3→baking 4→brushing 5→finishing 6.

[0025] In the feeding step: cutting the dandelion fibers into short fibers with a length between 0.5 mm and a fiber fineness of about 12 microns in diameter; putting the cut dandelion fibers into a flocking box.

[0026] In the step of applying and scraping the adhesive, the flocking base cloth adopts the specification of cotton weft elastic fabric: warp cotton 60 s ×Weft cotton bale spandex 60 s +30D, the warp and weft density is 172×76 / inch, and the door width is 44 inches.

[0027] In the described scraping adhesive step, apply adhesive on the flocking base cloth, described adhesive adopts zr-961 electrostatic flocking adhesive:

[0028] (1) Glue compounding: add 40% ammonia water to the acrylate emulsion to adjust the viscosity, and thicken the emulsion to 10 Pa.s;

[0029] (2) Gl...

specific Embodiment 2

[0034] A method for processing dandelion fiber electrostatic flocking, comprising the following steps: feeding 1→scraping adhesive 2→electrostatic flocking 3→baking 4→brushing 5→finishing 6.

[0035] In the feeding step: cutting the dandelion fibers into short fibers with a length of 0.8 mm and a fiber fineness of about 12 microns in diameter; putting the cut dandelion fibers into a flocking box.

[0036] In the step of applying and scraping the adhesive, the flocking base cloth adopts the specification of cotton weft elastic fabric: warp cotton 60 s ×Weft cotton bale spandex 60 s +30D, the warp and weft density is 172×76 / inch, and the door width is 44 inches.

[0037] In the described scraping adhesive step, apply adhesive on the flocking base cloth, described adhesive adopts zr-961 electrostatic flocking adhesive:

[0038](1) Glue compounding: add 40% ammonia water to the acrylate emulsion to adjust the viscosity, and thicken the emulsion to 20 Pa.s;

[0039] (2) Glue amo...

specific Embodiment 3

[0044] A method for processing dandelion fiber electrostatic flocking, comprising the following steps: feeding 1→scraping adhesive 2→electrostatic flocking 3→baking 4→brushing 5→finishing 6.

[0045] In the feeding step: cutting the dandelion fibers into short fibers with a length between 0.7 mm and a fiber fineness of about 12 microns in diameter; putting the cut dandelion fibers into a flocking box.

[0046] In the step of applying and scraping the adhesive, the flocking base cloth adopts the specification of cotton weft elastic fabric: warp cotton 60 s ×Weft cotton bale spandex 60 s +30D, the warp and weft density is 172×76 / inch, and the door width is 44 inches.

[0047] In the described scraping adhesive step, apply adhesive on the flocking base cloth, described adhesive adopts zr-961 electrostatic flocking adhesive:

[0048] (1) Glue compounding: add 40% ammonia water to the acrylate emulsion to adjust the viscosity, and thicken the emulsion to 14 Pa.s;

[0049] (2) Gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com