Novel high-grade powder coating and preparation method thereof

A powder coating, a new technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problem that the lubricity of powder coatings cannot meet the needs of use, poor impact strength and acid and alkali resistance, and oxidative decomposition of body resins, etc. Problems, to achieve the effect of shortening the curing time, good coating effect, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Embodiment: A new type of high-grade powder coating and its preparation method. The raw materials of the powder coating include epoxy resin, weather-resistant resin, pigment, filler, aluminum silver powder, hardening auxiliary agent and other auxiliary agents. The raw materials are formulated as: E -12 Epoxy resin 30-35%, weather-resistant resin 30-35%, pigment and filler mixture 20-30%, aluminum silver powder 1-3%, hardening aid 0.5-1.5%, other additives 1-3%, The weather-resistant resin is specifically polyester resin, the acid value of polyester resin is 70.7 mgKOH / g, the hardening aid is polypropylene compound, and other additives are one or both of leveling agent and brightening agent.

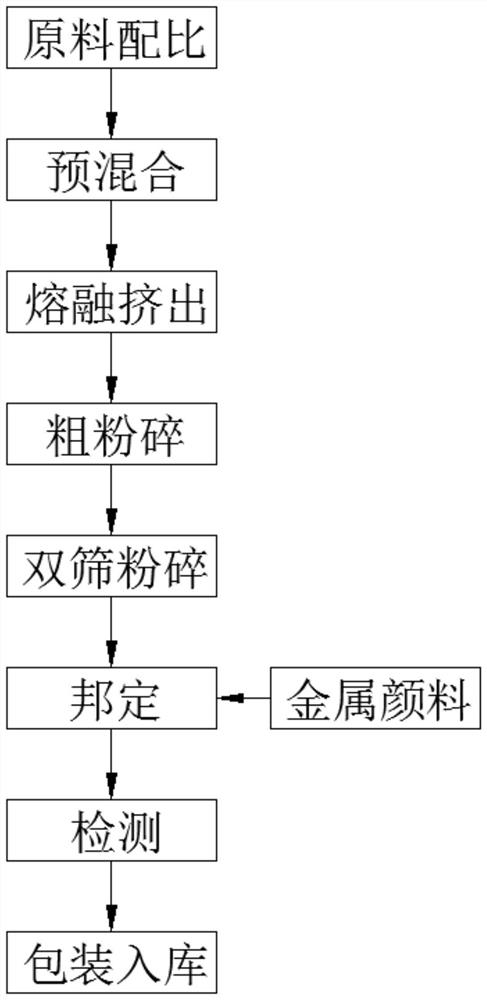

[0034] refer to figure 1 Shown: a kind of preparation method of novel high-grade powder coating, the concrete steps of the preparation method of powder coating are as follows:

[0035] S1: Raw material ratio

[0036] Install the raw materials in their corresponding parts by weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com