Manufacturing method for disposable sanitary base material and production line thereof

A manufacturing method, a one-time technology, applied in the direction of chemical instruments and methods, layered products, laminating devices, etc., can solve the problem of increasing intermediate transportation links and transportation costs, hidden dangers of skin safety in the amount of glue used, and a large amount of glue used for bonding and other problems, to achieve the effect of reducing production steps and links, reducing transportation volume, and reducing the amount of glue used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

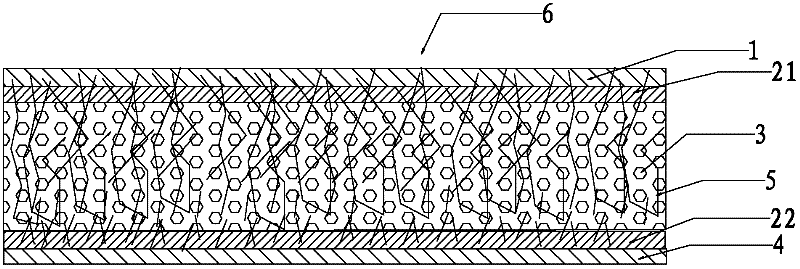

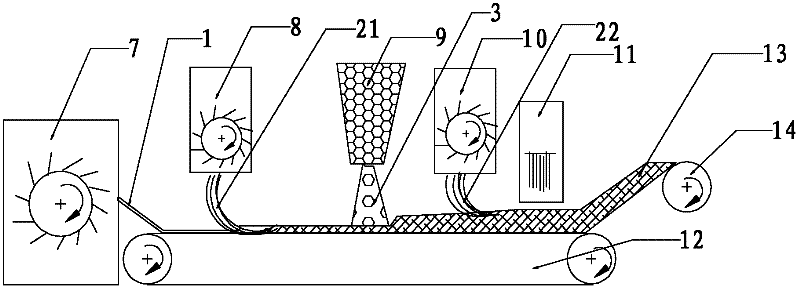

[0045] like figure 2 As shown, the surface layer 1 is realized by the first carding equipment 7 using the carding process, which is composed of short fiber hydrophilic treatment→drying→short fiber feeding and weighing→mixing and opening→multi-compartment blending→cotton transportation →air fiber separation→cotton box→opening→cotton feeding→repeated opening→repeated feeding→feeding→carding→laying to form surface layer 1 with fiber fineness between 1.5-4 denier. The first cladding layer (guiding layer) 21 is realized by the second carding equipment 8 carding process, but the fiber fineness will be smaller than the surface layer 1, between 0.1-2 deniers, the first cladding layer (The diversion layer) 21 is superimposed on the surface layer 1, and is transported to the paving equipment 9 by the mesh belt 12, and the superabsorbent resin or fluff pulp is evenly spread on the superimposed surface layer 1 and the first cladding layer 2, The absorbent layer 3 is formed; the paving e...

Embodiment 2

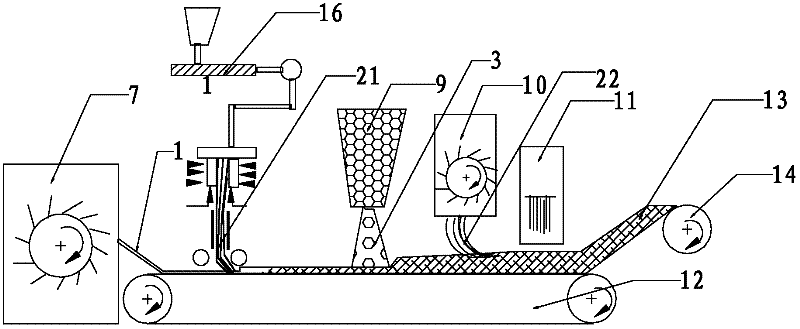

[0047] like image 3As shown, the difference between this embodiment and the first embodiment is mainly that: the fiber web of the first coating layer 21 is realized by the second spinning equipment 16 using the spinning process, and the spinning process includes: high The raw material of polymer chips and the hydrophilic masterbatch are transported together → quantitative mixing and feeding → screw extruder melt extrusion → melt filtration → metering pump quantitative metering → melt distribution → spinneret spinning → fiber quenching → fiber airflow Drafting → fiber splitting and laying. In this example, the second spinning device 16 is a spunbond spinning device.

Embodiment 3

[0049] like Figure 4 As shown, the surface layer 1 is realized by the first spinning device 15 using the spinning process. The spinning process includes: co-transporting the high polymer chip raw material and the hydrophilic masterbatch → quantitative mixing and feeding → screw Extruder melt extrusion → melt filtration → quantitative metering by metering pump → melt distribution → spinneret spinning → fiber quenching → fiber airflow drafting → fiber splitting and laying to form surface layer 1, and the fiber fineness is in Between 1-4 denier. The fiber web of the first cladding layer 21 is realized by the second spinning device 16 by the spinning process, but the fiber fineness is smaller than that of the surface layer 1 fiber web, which is between 0.1-2 denier. The covering layer 21 is superimposed on the surface layer 1 and transported to the spreading equipment 9 through the mesh belt 12 . With the movement of the mesh belt 12 , a second coating layer 22 is laid on the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com