Method of making liquid crystal polymer films

A technology of liquid crystal polymers and manufacturing methods, applied in liquid crystal materials, printed circuit manufacturing, chemical instruments and methods, etc., capable of solving problems such as positional deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

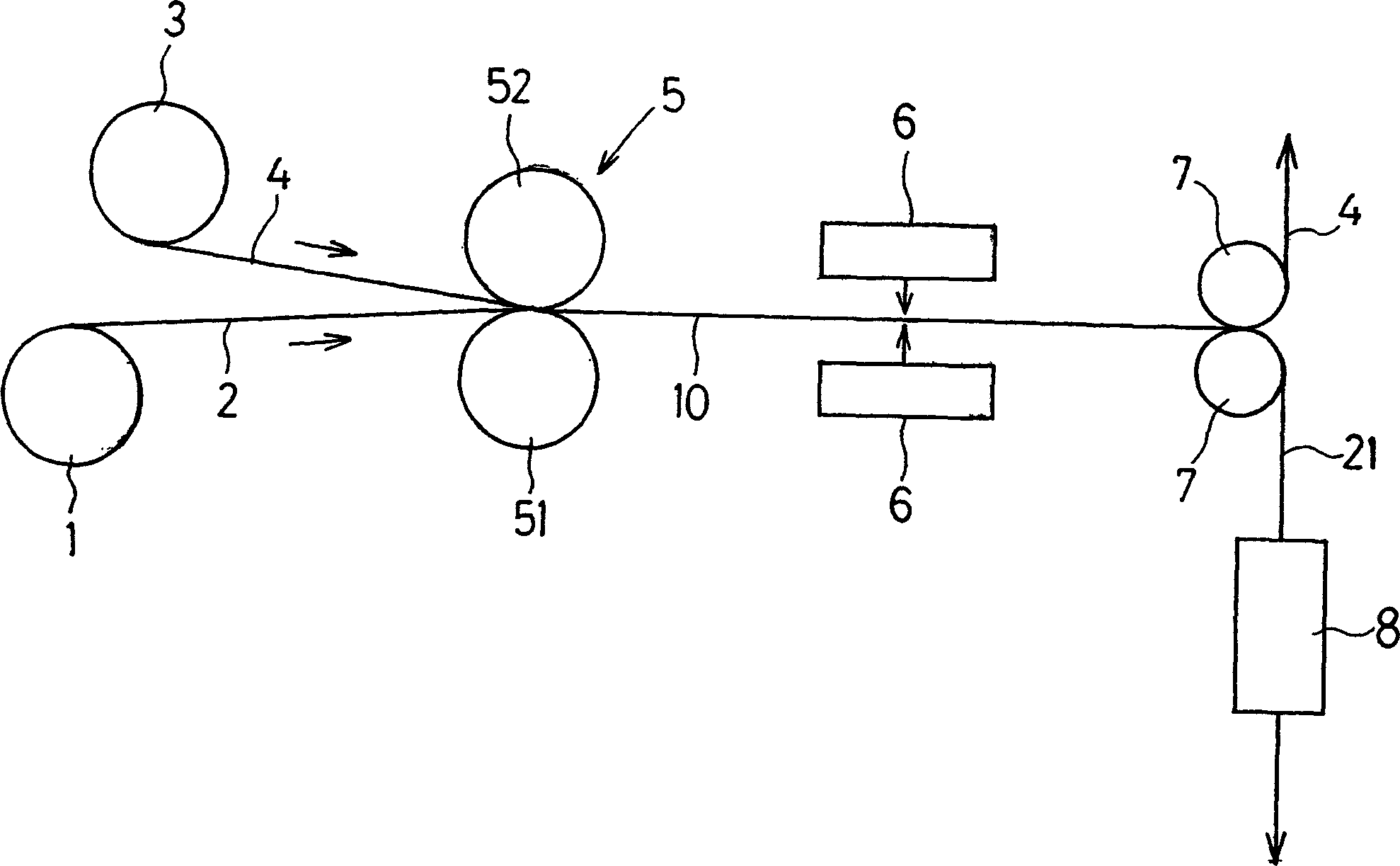

Embodiment 1

[0077] Use the thermoplastic liquid crystal polymer film that obtains in the reference example and the aluminum foil of thickness 50 μ m (thermal expansion coefficient (S) is 23 * 10 -6 cm / cm / °C) as a support. A heat-resistant rubber roll (hardness 90 degrees, JISA) and a heated metal roll are installed in a continuous hot roll extrusion device, and the thermoplastic liquid crystal polymer film is supplied between the rolls by contacting the heat-resistant rubber roll surface and the aluminum foil is in contact with the heated metal roll surface, 10kg / cm in 260℃ heating state 2 Pressure bonding was performed, and a laminate composed of a thermoplastic liquid crystal polymer film / aluminum foil was produced at a speed of 3 m / min. At this time, a tension of 3 kg / 40 cm width was applied to the thermoplastic liquid crystal polymer film. A part of the obtained laminate was sampled, the aluminum foil and the film were peeled off, and the result of measuring the coefficient of therm...

Embodiment 2

[0081] Using the thermoplastic liquid crystal polymer film obtained in the reference example and a titanium foil with a thickness of 30 μm (the coefficient of thermal expansion (S) is 9×10 -6 cm / cm / °C) as a support. A heat-resistant rubber roll (hardness 90 degrees, JISA) and a heated metal roll are installed in a continuous hot roll extrusion device, and the thermoplastic liquid crystal polymer film is brought into contact with the heat-resistant rubber roll surface and titanium foil is supplied between the rolls by contacting the heat-resistant metal roll surface , heated at 260°C at 10kg / cm 2 Pressure bonding was performed, and a laminate composed of a thermoplastic liquid crystal polymer film / titanium foil was produced at a speed of 3 m / min. At this time, a tension of 3 kg / 40 cm width was applied to the thermoplastic liquid crystal polymer film. A part of the obtained laminate was sampled, the titanium foil and the film were peeled off, and the result of measuring the th...

Embodiment 3

[0085] Using the thermoplastic liquid crystal polymer film obtained in the reference example and copper foil with a thickness of 18 μm (the coefficient of thermal expansion (S) is 18×10 -6 cm / cm / °C) as a support. A heat-resistant rubber roll (hardness 90 degrees, JISA) and a heated metal roll are installed in a continuous heat-roll extrusion device, and the thermoplastic liquid crystal polymer film contacts the surface of the heat-resistant rubber roll and the copper foil contacts the surface of the heated metal roll to supply between the rolls , heated at 260°C at 10kg / cm 2 Pressure bonding was performed, and a laminate composed of a thermoplastic liquid crystal polymer film / copper foil was produced at a speed of 3 m / min. At this time, a tension of 3 kg / 40 cm width was applied to the thermoplastic liquid crystal polymer film. A part of the obtained laminate was sampled, the copper foil and the film were peeled off, and the result of measuring the coefficient of thermal expa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com