ERP-based intelligent intensive control system of continuous dyeing production line

A control system and production line technology, applied in the direction of total factory control, total factory control, electrical program control, etc., to achieve the effect of avoiding production interruption, ensuring production efficiency, and improving enterprise benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

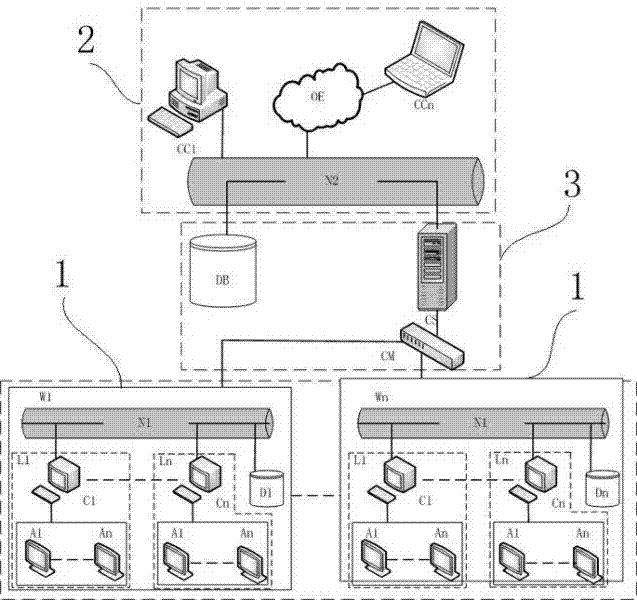

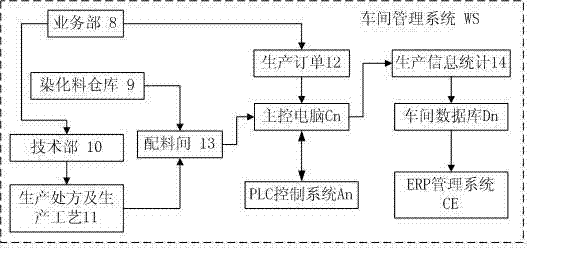

[0023] see figure 1 , an ERP-based intelligent intensive control system for a continuous dyeing production line, consists of a workshop-level monitoring system 1, an enterprise-level management system 2, and an intermediate information management system 3 for connecting the workshop-level monitoring system 1 and the enterprise-level management system 2. The workshop-level monitoring system 1 connects all workshops W1 to Wn in the enterprise through the workshop control network N1 to realize data sharing. The continuous dyeing production lines L1 to Ln in each workshop W1 to Wn are divided into several stations A1 to An according to the process requirements, such as water washing, cloth fall waste heat control, etc. The system is equipped with a set of PLC control system for each station .

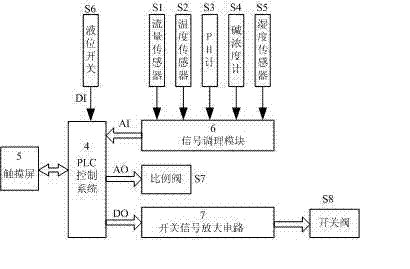

[0024] see figure 2 , The PLC control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com