Method for vulcanizing nitrile elastomer

A technology of elastomers and nitriles, applied in the field of vulcanization of nitrile elastomers, can solve problems such as scarcity of technology, and achieve the effect of simple vulcanization system and non-toxic crosslinking agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

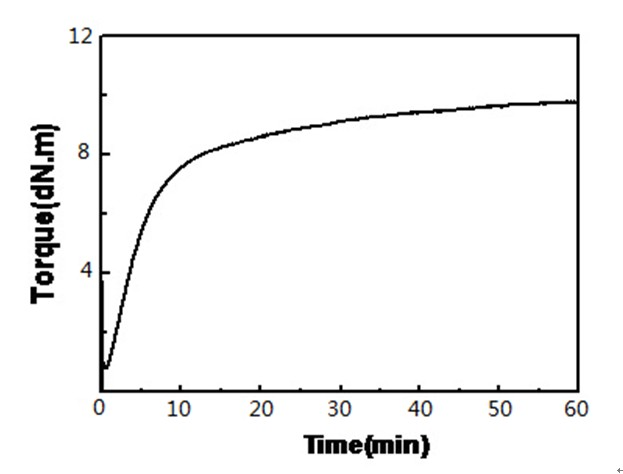

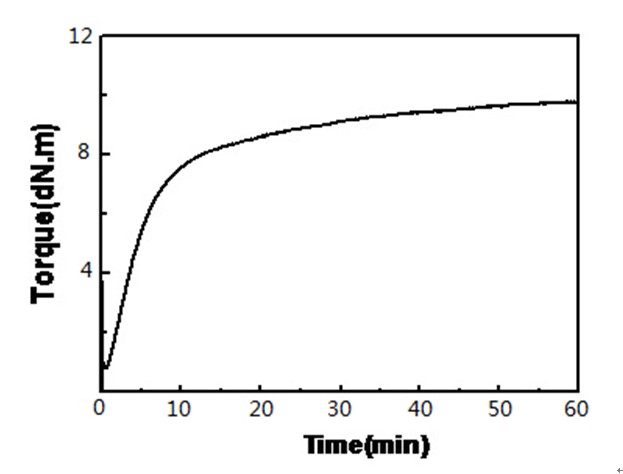

[0018] Put 100 kg of nitrile rubber resin and 55 kg of tartaric acid into the open mill at one time, and mix evenly at 45 ° C to obtain a compound rubber; then quickly send the compound rubber to a flat vulcanizing machine at a temperature of 180 ° C for vulcanization. After 60 min, the material was discharged and cooled to obtain a vulcanized nitrile elastomer. The vulcanization characteristic parameters tested according to the national standard: positive vulcanization time t 90 =20.83min, minimum torque M L =0.82dN·m, the maximum torque M H =9.60 dN·m, torque increment △M=8.78 dN·m.

Embodiment 2

[0020] Put 100 kg of nitrile rubber resin and 45 kg of malic acid into the internal mixer at one time, and mix evenly at 20°C to obtain a compound rubber; then quickly send the compound rubber into a flat vulcanizing machine at a temperature of 200°C for vulcanization , After 30 minutes, the material is discharged, cooled, and the vulcanized nitrile elastomer is obtained. The vulcanization characteristic parameters tested according to the national standard: positive vulcanization time t 90 =6.32min, minimum torque M L =0.74dN·m, the maximum torque M H =9.32 dN·m, torque increment △M=8.58 dN·m.

Embodiment 3

[0022] Put 100 kg of nitrile rubber resin and 25 kg of mixed hydroxycarboxylic acid mixed with tartaric acid and malic acid at a weight ratio of 4:1 into the internal mixer at one time, and mix evenly at 35°C to obtain a compound compound ; Then, the composite rubber is quickly sent to a flat vulcanizing machine at a temperature of 135°C for vulcanization, and it is discharged after 60 minutes and cooled to obtain a vulcanized nitrile elastomer. The vulcanization characteristic parameters tested according to the national standard: positive vulcanization time t 90 =44.21min, minimum torque M L =0.77dN·m, the maximum torque M H =8.68 dN·m, torque increment △M=7.91 dN·m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com