Dual-stage-ceiling Chinese style structure framework room prepared from aluminum profile

A technology of structural frame and aluminum profiles, which is applied in the direction of building construction and construction, can solve the problems of lack of Chinese-style structural houses and other problems, achieve the effects of rich types, avoiding damage to material structures, and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

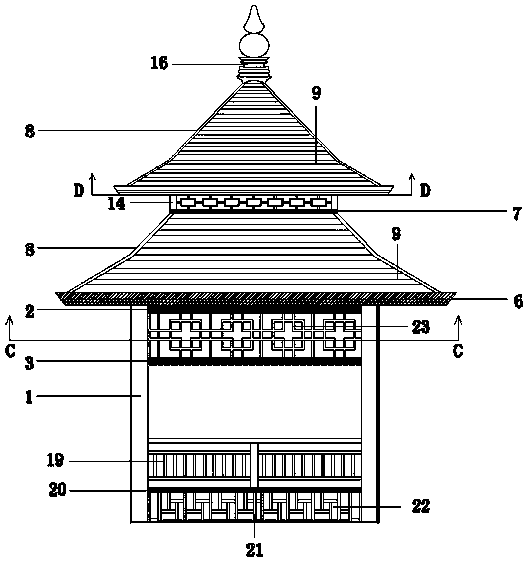

[0064] Such as figure 1 , 3 -8. As shown in 11-16, the double-stage roof Chinese-style frame house made of aluminum profiles described in this embodiment is a four-corner, square-section structure, including a frame support mechanism, a first-stage roof mechanism, and a second-stage roof mechanism. The frame The support mechanism includes four frame support modules, wherein a single frame support module is composed of a composite column 1, an upper frame beam 2, and a lower frame beam 3, and two adjacent frame support modules share a composite column at the junction of the two 1.

[0065] The composite column 1 is assembled in a "four-in-one" form using a connecting mechanism, and four column members 101 with an outer square and an inner circle are connected to form a composite column 1 through the connecting mechanism, that is, four square column members with an outer square and an inner circle are used. 101 is combined through a connecting mechanism; the connecting mechani...

Embodiment 2

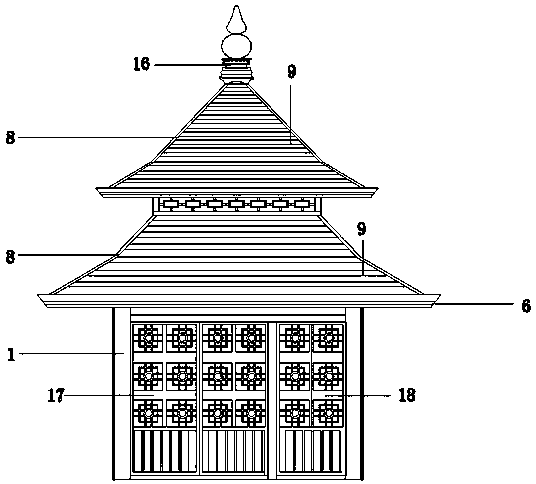

[0080] Such as figure 2 , 3, 4, 5, 6, 9, 11-16, the double-stage roof Chinese-style frame house made of aluminum profiles described in this embodiment is a four-corner structure with a square cross-section, including a frame support mechanism, a first-stage roof mechanism, Two-level top mechanism; the frame support mechanism includes four frame support modules, a single frame support module is composed of a composite column 1, an upper frame beam 2, and a lower frame beam 3, and two adjacent frame support modules share a two The composite column 1 at the joint, the composite column 1 is a hollow cylinder, and four quarter circular column members 101 are combined through the connection mechanism; the overall is basically the same as that described in embodiment 1, the difference is that, It also includes a frame door mechanism 17 and an antique window mechanism 18, the frame door mechanism 17 is installed between the composite column 1 and the wall panel composed of aluminum ...

Embodiment 3

[0084] Such as Figure 17-22 As shown, the structure of the double-stage roof Chinese-style frame house prepared from the aluminum profiles described in this embodiment is basically the same as that of Embodiment 1, the difference is that in order to improve the bending arc of the structure of the flying lamp 8, it is more in line with the traditional In the style of the building, two levels of warping parts 802 are connected to each other to obtain a large-arc upturned flying cup 8 structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com