Circuit printing method through uniform metal liquid drops

A metal droplet, uniform technology, applied in other manufacturing equipment/tools, turbines, engine components, etc., can solve the problems of poor practicability, achieve good practicability, meet the bonding strength, and reduce post-processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

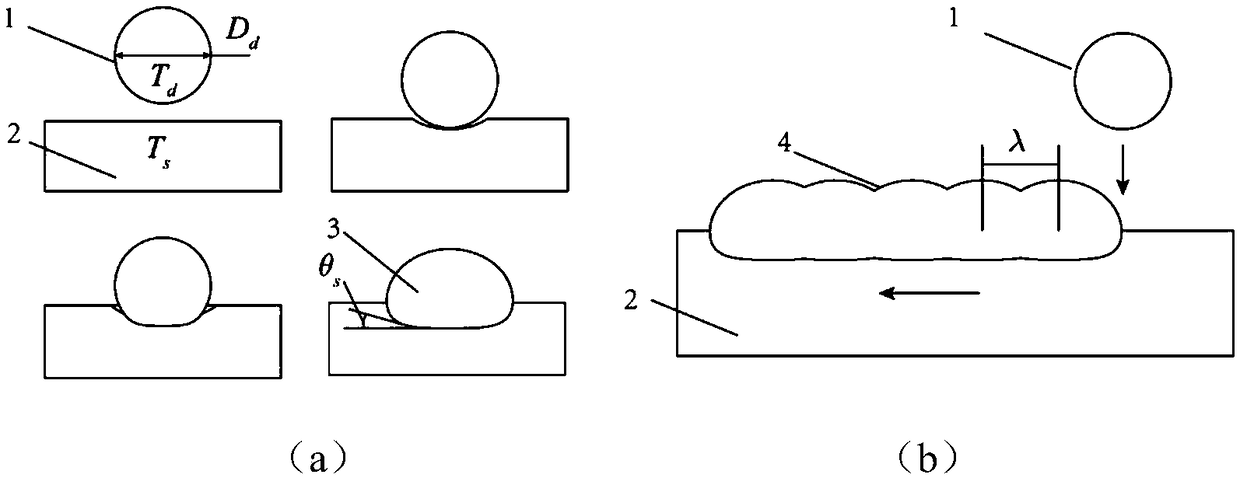

[0026] Example 1. Printing of electronic circuits on thermoplastic substrates.

[0027] Lead-tin alloy (ZHLZn60PbA) was used as the printing material, and organic glass (polymethyl methacrylate) was used to process the thermoplastic substrate 2. First, heat the lead-tin alloy inside the crucible to 300°C-400°C, match the pressure amplitude, pulse width and frequency of the metal droplet injection, and realize the stable injection of a single uniform metal droplet 1.

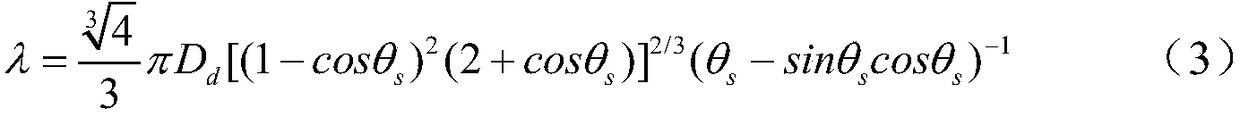

[0028] in accordance with:

[0029] T d > T g (1)

[0030] ρV d C(T d -T s )>ρV 搭接 C(T d -T s )+ρV 搭接 H (2)

[0031] Calculate the temperature T of the high-temperature metal droplet 1 d with thermoplastic matrix 2 temperature T s . T d The value range is: T d =300℃~400℃, T s The value range is: T s =100°C to 200°C. The metal droplet 1 is sprayed with a diameter of about 200-500 μm, so that it is precisely positioned on the surface of the thermoplastic substrate 2 . The metal droplet 1 melts...

Embodiment 2

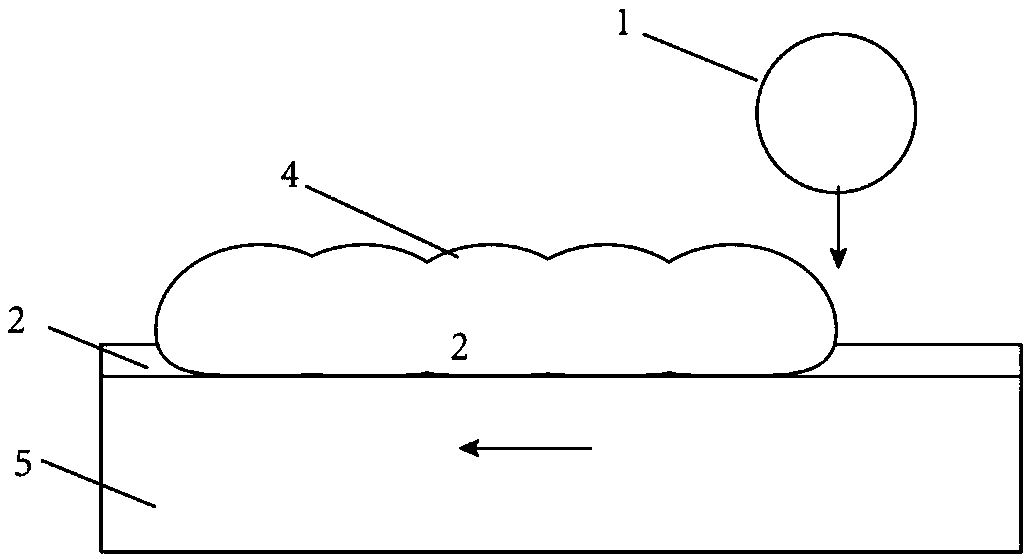

[0035] Example 2. Fast printing of highly conductive electronic circuits on high melting point substrates.

[0036] For high-melting-point insulating substrates 5 such as glass and ceramics, a thermoplastic layer 2 is firstly coated on the surface to prepare a composite substrate for printing metal droplets 1 . The gold-tin alloy (AuSn30) was used as the printing material, and the personalized circuit was directly printed on the prepared composite substrate.

[0037] in accordance with:

[0038] T d > T g (1)

[0039] ρV d C(T d -T s )>ρV 搭接 C(T d -T s )+ρV 搭接 H (2)

[0040] Calculate the temperature T of the high-temperature metal droplet 1 d with thermoplastic matrix 2 temperature T s . T d The value range is: T d =400℃~500℃, T s The value range is: T s =100°C to 200°C. Spray metal droplet 1 with a diameter of about 200-500 μm, and conduct gold-tin alloy droplet deposition test on thermoplastic substrate 2 to obtain good fusion between metal droplet 1 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com