A permanent magnet two-phase brushless divided stator motor

A permanent magnet rotor and stator technology, applied in the field of electric motors, can solve problems such as motor vibration and noise, and achieve the effects of overcoming vibration and noise, fast speed, and saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

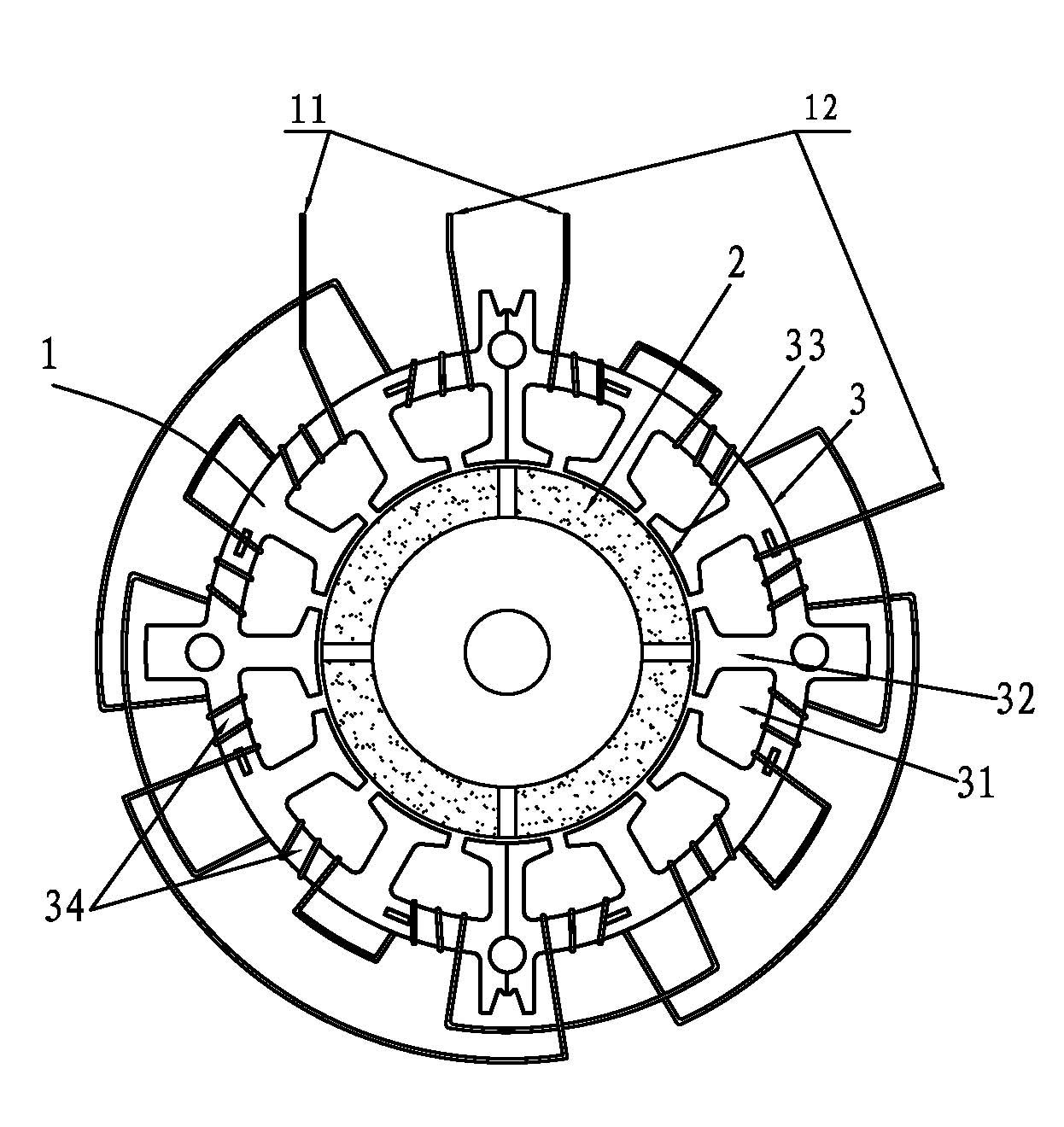

[0026] Such as figure 1 As shown, a permanent magnet two-phase brushless motor with divided stators includes a stator 1, a main winding 11, an auxiliary winding 12, a permanent magnet rotor 2 and a starting device. The stator 1 is composed of two divided stators 3, and the divided stators The slot number 31 of 3 is a multiple of 3, and the sum of the slot numbers of the stator is a multiple of 6; for example figure 1 As shown, the number of slots of the sub-stator 3 is 6, and the total number of slots of the stator is 12; the stator teeth 32 and the permanent magnet rotor 2 have no eccentric air gap 33 .

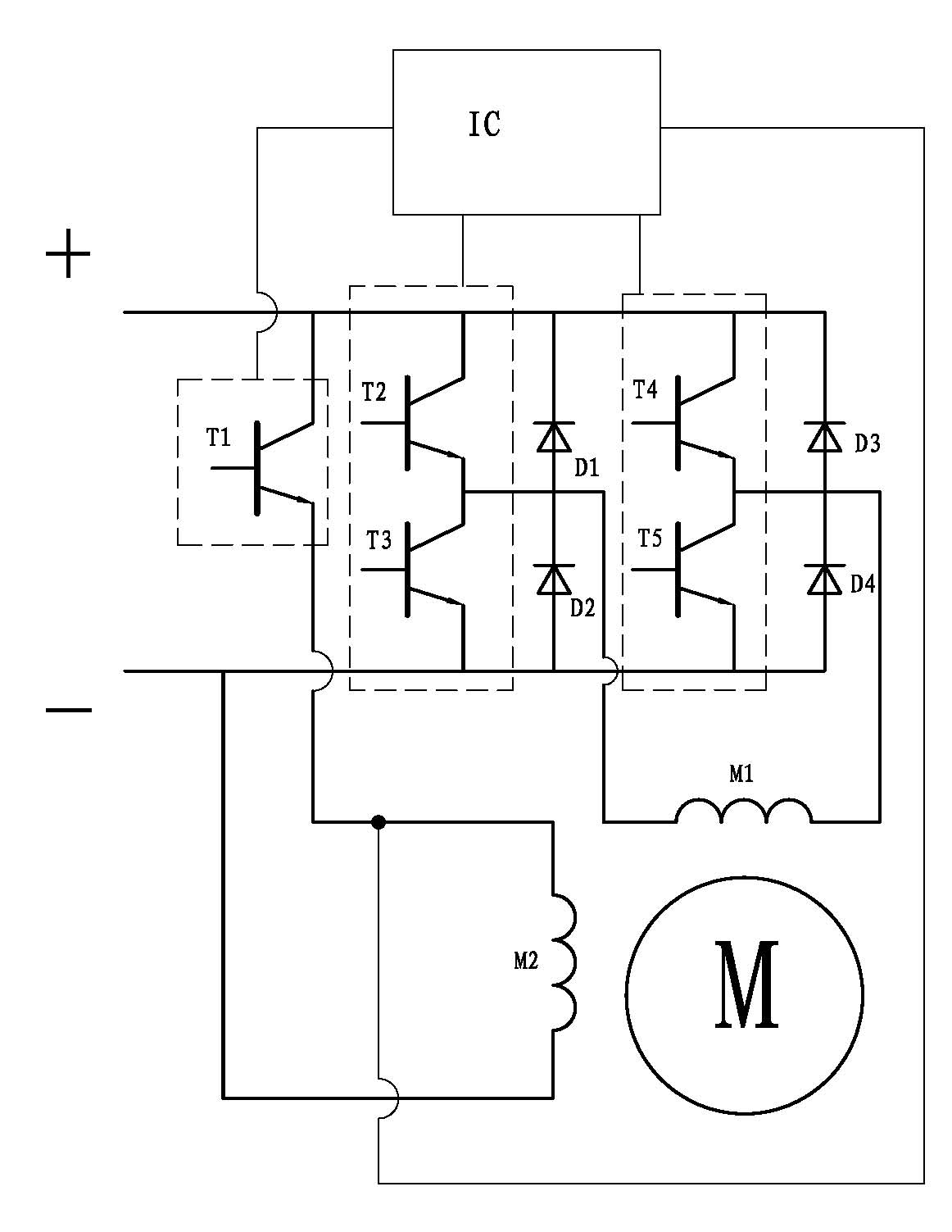

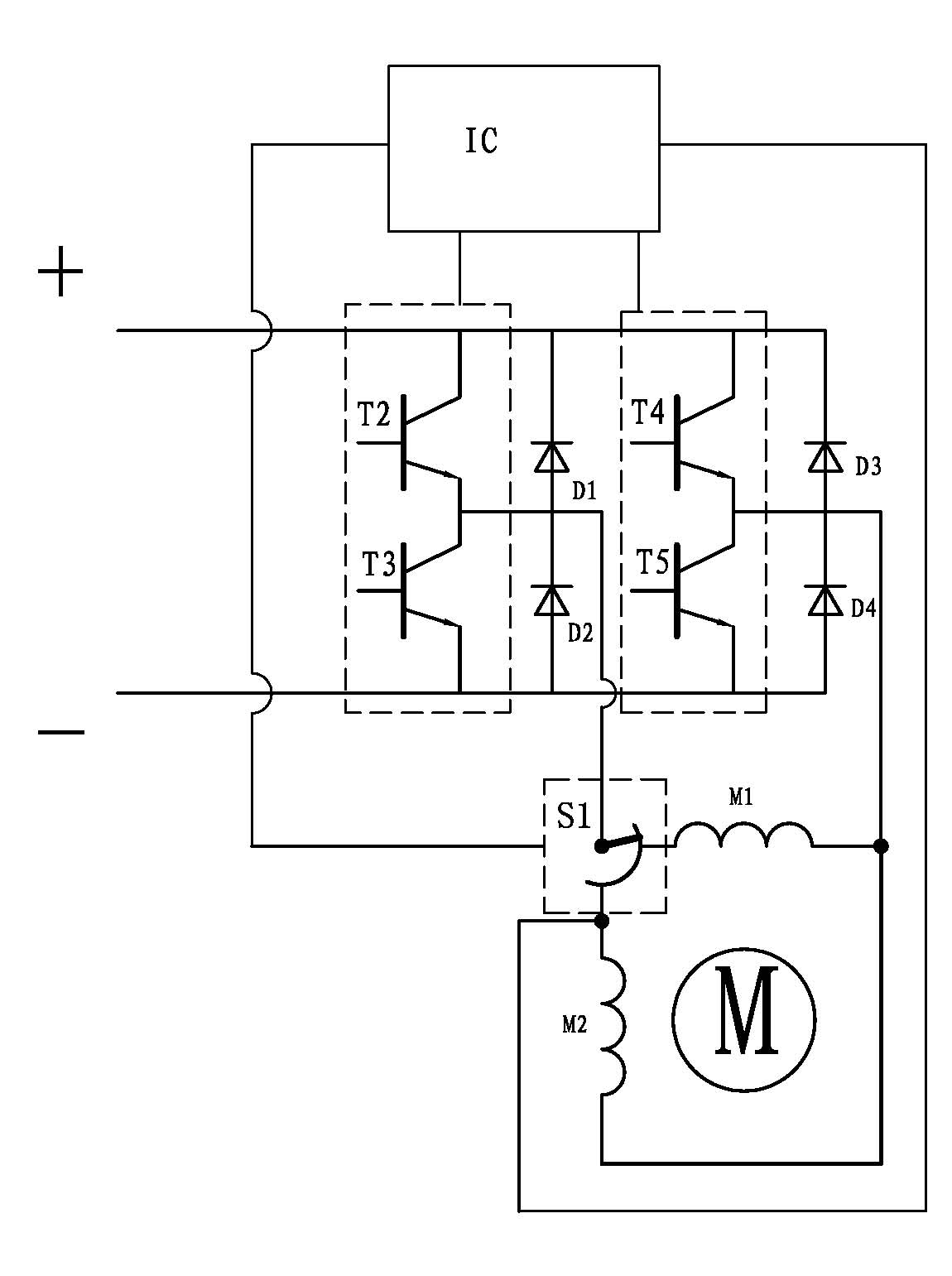

[0027] The main winding and the auxiliary winding adopt the distributed winding method on the stator. The ratio of the number of slots between the main winding and the auxiliary winding is 2:1. The main winding is reversely wound, the secondary winding is reversely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com