Single-line multi-pole outer rotor three-phase generator

An external rotor and generator technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problem of heavy generator weight and copper consumption Too many materials and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

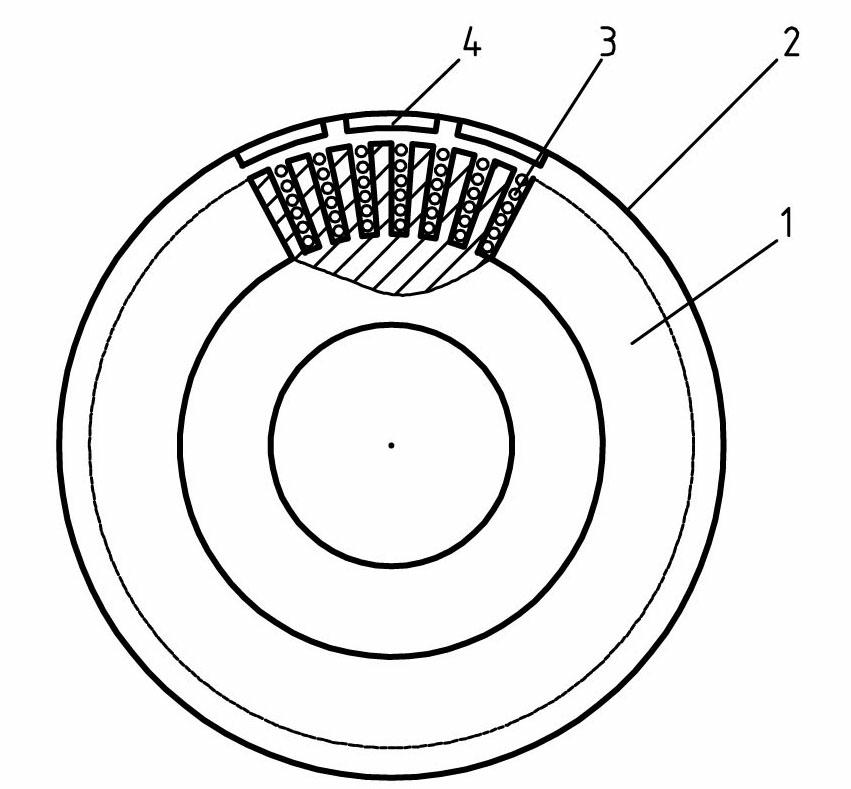

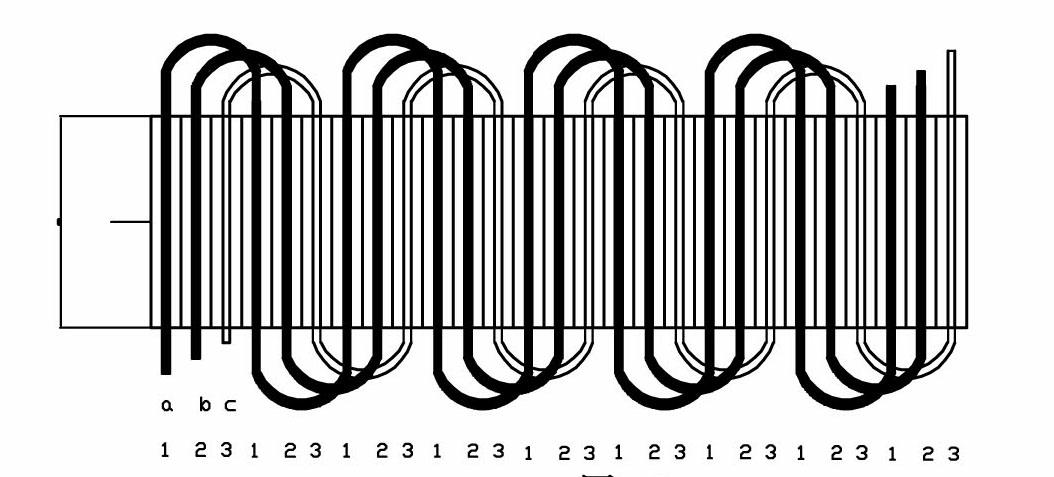

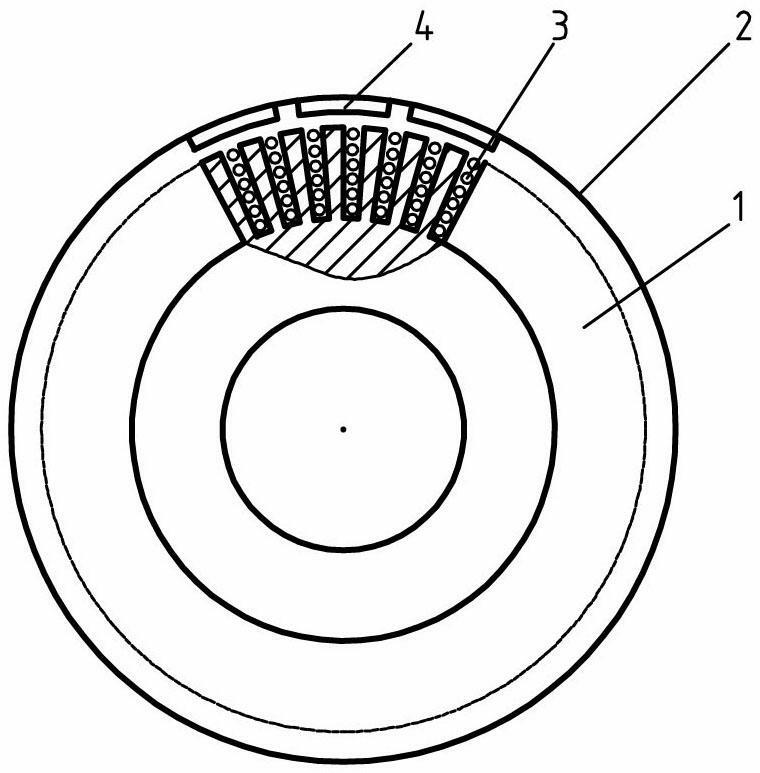

[0013] like figure 1 As shown, the single-wire multi-pole outer rotor three-phase generator of the present invention includes a stator 1, a casing 2, a generator winding 3, a permanent magnet 4, and the like. The stator 1 is installed in the casing 2, and the stator 1 is formed by stacking several silicon steel sheets, and the stacking direction of the silicon steel sheets is parallel to the axis of the casing 2. A number of wire slots arranged radially are processed on the stator 1, and a generator winding 3 is installed in the wire slots. The wire slots are evenly distributed on the outer edge of the stator 1 radially, and the outer ends of the wire slots are open. Several pieces of permanent magnetic steel 4 are installed on the inner wall of the casing 2 . In the permanent magnets 4 , the same ends of two adjacent permanent magnets 4 hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com