Electrical connecting part

An electrical connection and component technology, applied in the direction of electrical components, structural connections, electric components, etc., can solve the problems of increasing the difficulty of precise positioning of the electrical seat, the brush basin and the casing, the number of electrical connection components, and the increase of materials and processes. , to achieve the effect of material saving, less processing steps, and not easy to detach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

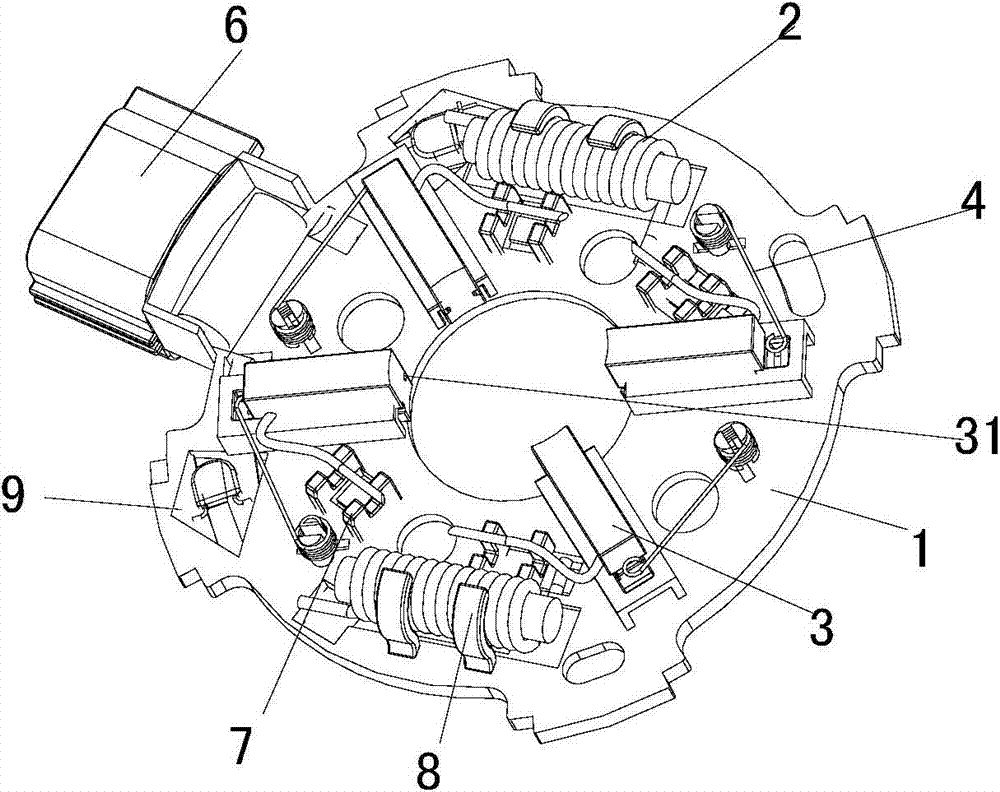

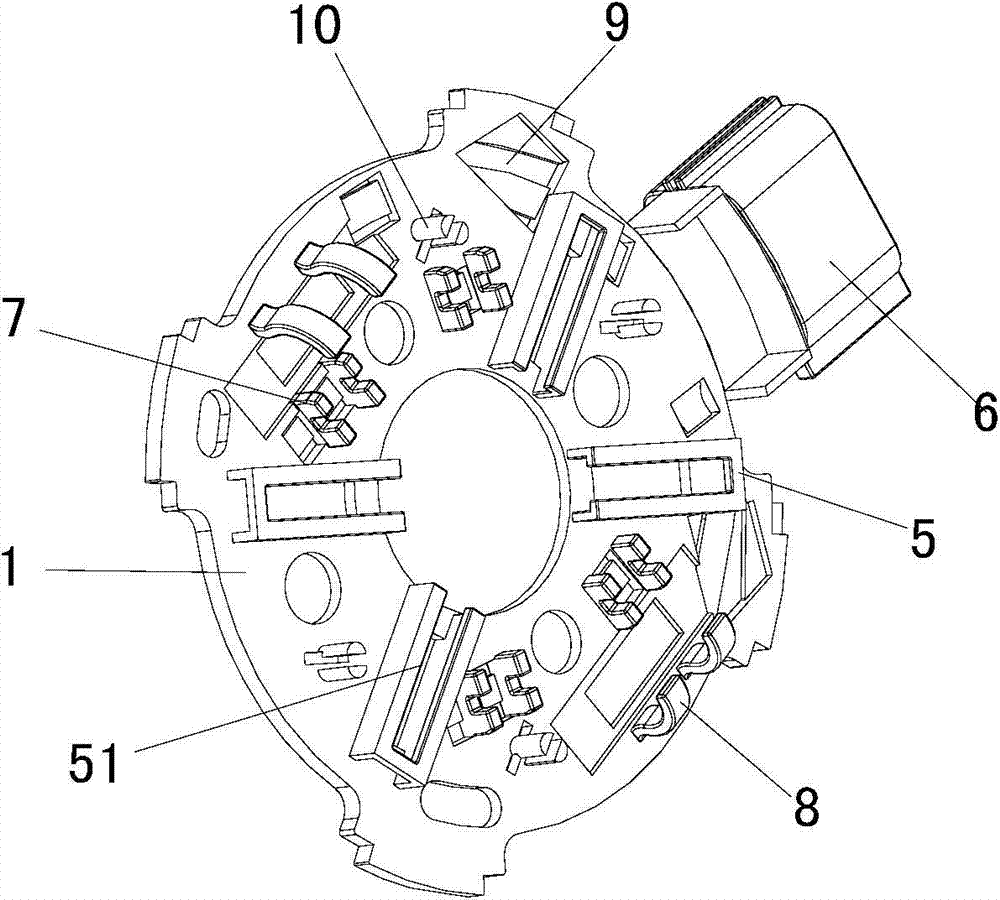

[0022] see figure 1 , figure 2 , the electrical connection part of the present invention includes a brush basin 1 and an inductance assembly 2 installed on the brush basin, a brush 3 and a brush spring 4; a guide rail 5, an electrical seat 6, a positioning block 7, The inductance clip 8, the conductive connecting piece 9 and the opening column 10, the guide rail, the electrical seat, the positioning block, the inductance clip, the conductive connecting piece and the opening column are integrally formed with the brush basin body. The inductance assembly 2 is installed on the above-mentioned inductance clamp 8, the brush 3 is embedded on the above-mentioned guide rail 5, and the brush spring 4 is connected between the brush and the opening column.

[0023] The guide rail 5 in the present invention is a groove-shaped structural member, and both sides of its upper part are provided with inward folded edges 51, and there are no slide grooves 31 on both sides of the brush 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com