Winding stator used for air-conditioning outdoor fan motor and manufacturing method thereof

A manufacturing method and a technology of an external fan, applied in electromechanical devices, electric components, manufacturing motor generators, etc., can solve problems such as large ends of concentric windings, difficulty in automatic production, and complicated manufacturing processes, so as to reduce the difficulty of the process and realize Automated production, the effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

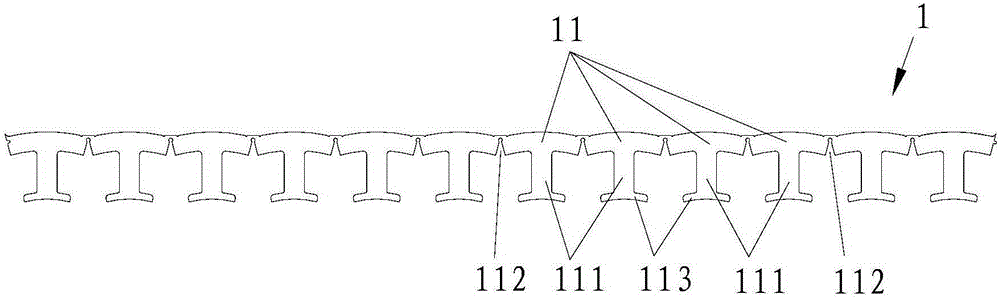

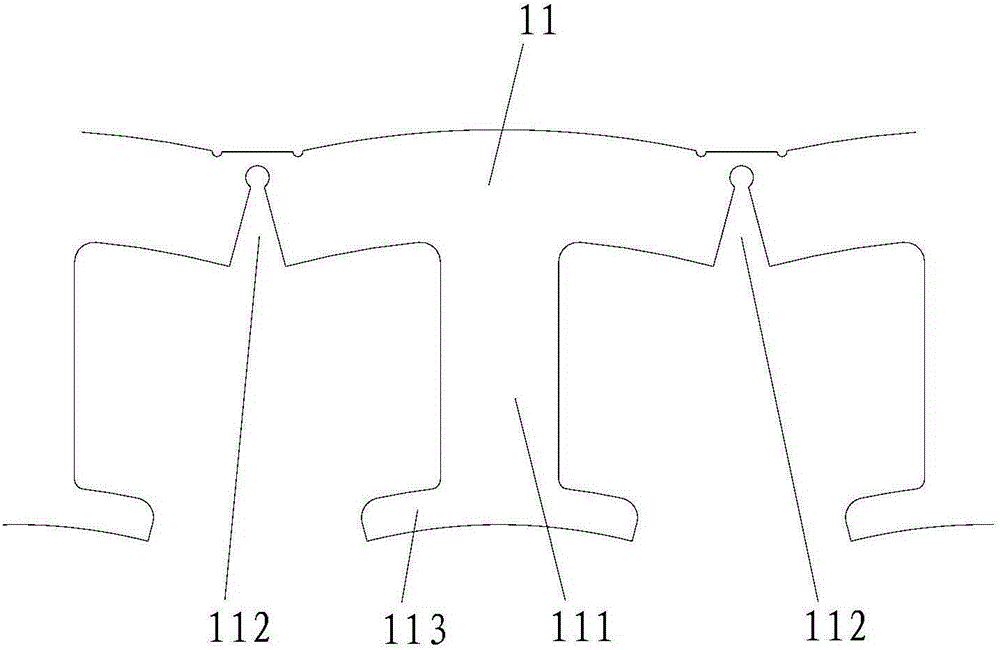

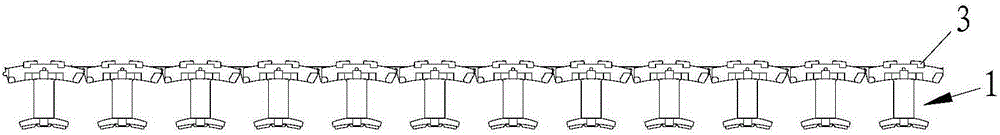

[0030] Below in conjunction with accompanying drawing, the present invention will be further described, see Figure 1~5 As shown, the winding stator for an air-conditioning outdoor fan motor of the present invention includes a stator punch 1 and a winding 2. The stator punch 1 is sequentially connected with each other by a plurality of punch blocks 11 to form a straight strip structure. The inner side of the block 11 protrudes integrally with a groove-shaped tooth portion 111 inwardly, and a plurality of stamping blocks 11 are integrally formed, which is convenient for processing. Insulation frames 3 are respectively fixed on the front and rear ends of the stator punching sheet 1, and the wires of the winding 2 are wound on the groove-shaped teeth 111 of each punching sheet block 11 in turn, and each punching sheet block 11 is sequentially wound along its joint to The inner bending makes the stator punching sheet 1 form a circular structure, and the two ends of the stator punc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com