Anti-loosing strong-anchoring fastener high in height adjustment

A fastener and anti-loosening technology, which is applied in roads, tracks, buildings, etc., can solve the problems that it is difficult to realize the negative adjustment and positive adjustment of large height adjustment, and the fastener bolts loosen the foundation of the track beam, so as to achieve fastener stability and low cost. Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

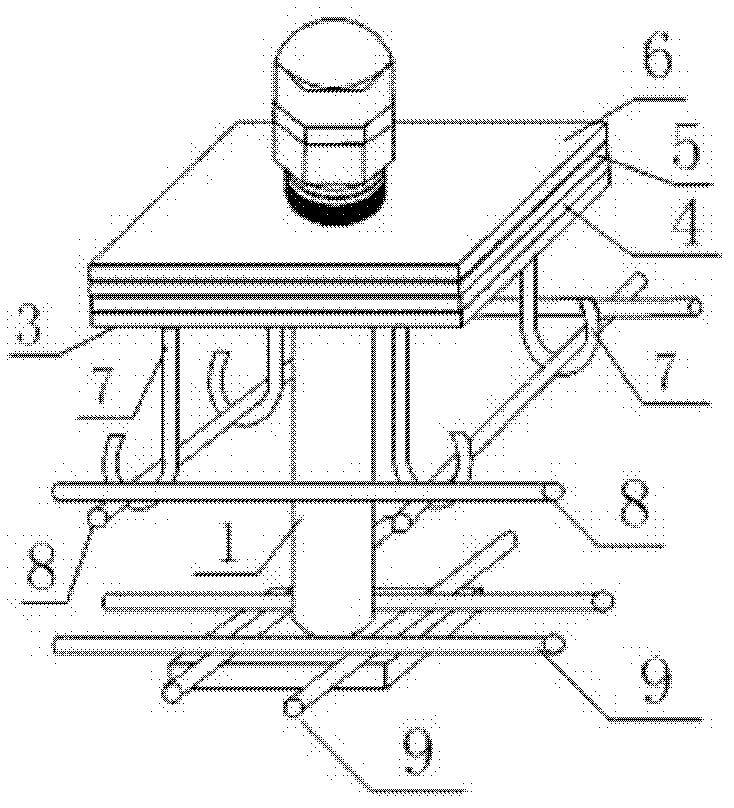

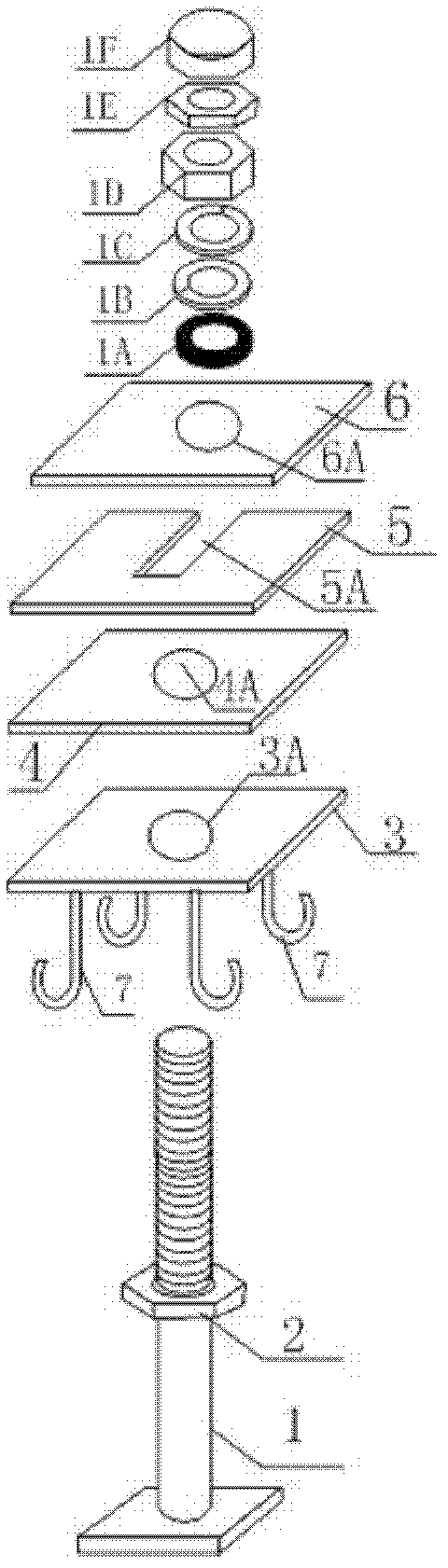

[0031] An anti-loosening strong anchoring large height adjustment fastener for the track row of medium and low speed maglev trains, which is composed of a bolt square head anchor structure, a bottom plate anchor structure, a rubber pad group, a height adjustment group, and a lock nut group; the bolt square head anchor Structure, floor anchoring structure, rubber pad group, height adjustment group, and lock nut group are arranged sequentially from bottom to top to form the main body of the fastener.

[0032] The bolt square head anchoring structure is composed of a square head of a square head bolt 1 and four bottom steel bars 9 arranged vertically and horizontally on it, and is anchored in grouting material or cement after the rail platform is poured. Such as figure 1 , figure 2 , image 3 , Figure 5 shown. The grouting material or cement is injected into a rectangular rail platform. The rail bearing platform is a rectangular or square platform made of grouting material...

Embodiment 2

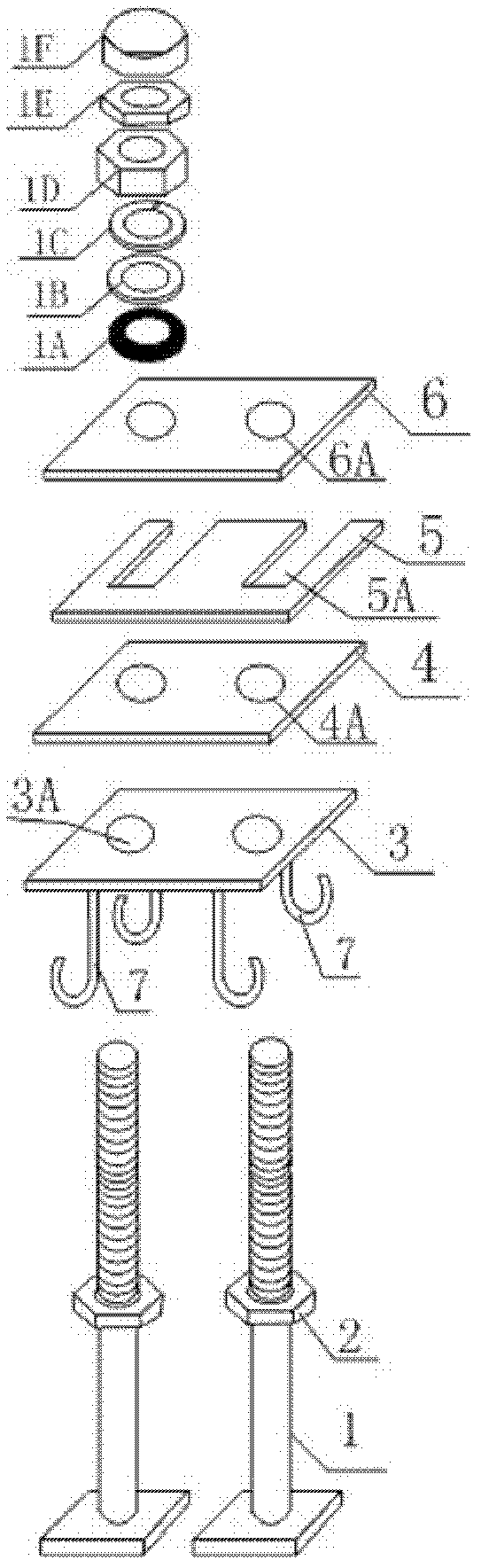

[0047] Others are with embodiment 1. The difference is that the fastener is a double anchor lag bolt fastener. The bolt square head anchoring structure is composed of the square heads of two square head bolts 1 and six bottom steel bars 9 arranged vertically and horizontally on them; the height adjustment group 5 is a set of rubber and plastic plates with two slots 5A , or nylon plate, or other steel plates and other materials, which are composed of one or two or more plates with a thickness of 0.1mm, 0.2mm, 0.5mm, 1mm, 2mm, 5mm, 10mm, or 20mm. After the total thickness of 20mm, its shape is E-type.

Embodiment 3

[0049] Others are with embodiment 1. The difference is that the fastener is a four-anchor lag bolt fastener. The bolt square head anchoring structure is composed of the square heads of four square head bolts 1 and eight underlying steel bars 9 vertically and horizontally arranged on them; the height adjustment group 5 is a set of rubber and plastic plates with two slots 5A , or nylon plate, or other steel plates and other materials, which are composed of one or two or more plates with a thickness of 0.1mm, 0.2mm, 0.5mm, 1mm, 2mm, 5mm, 10mm, or 20mm. After the total thickness of 20mm, its shape is E-type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com