Nut

A nut, threaded through-hole technology, applied in the direction of nuts, screws, bolts, etc., can solve problems such as difficulty in tightening, and achieve the effects of long service life, improved safety performance, and good anti-loosening performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

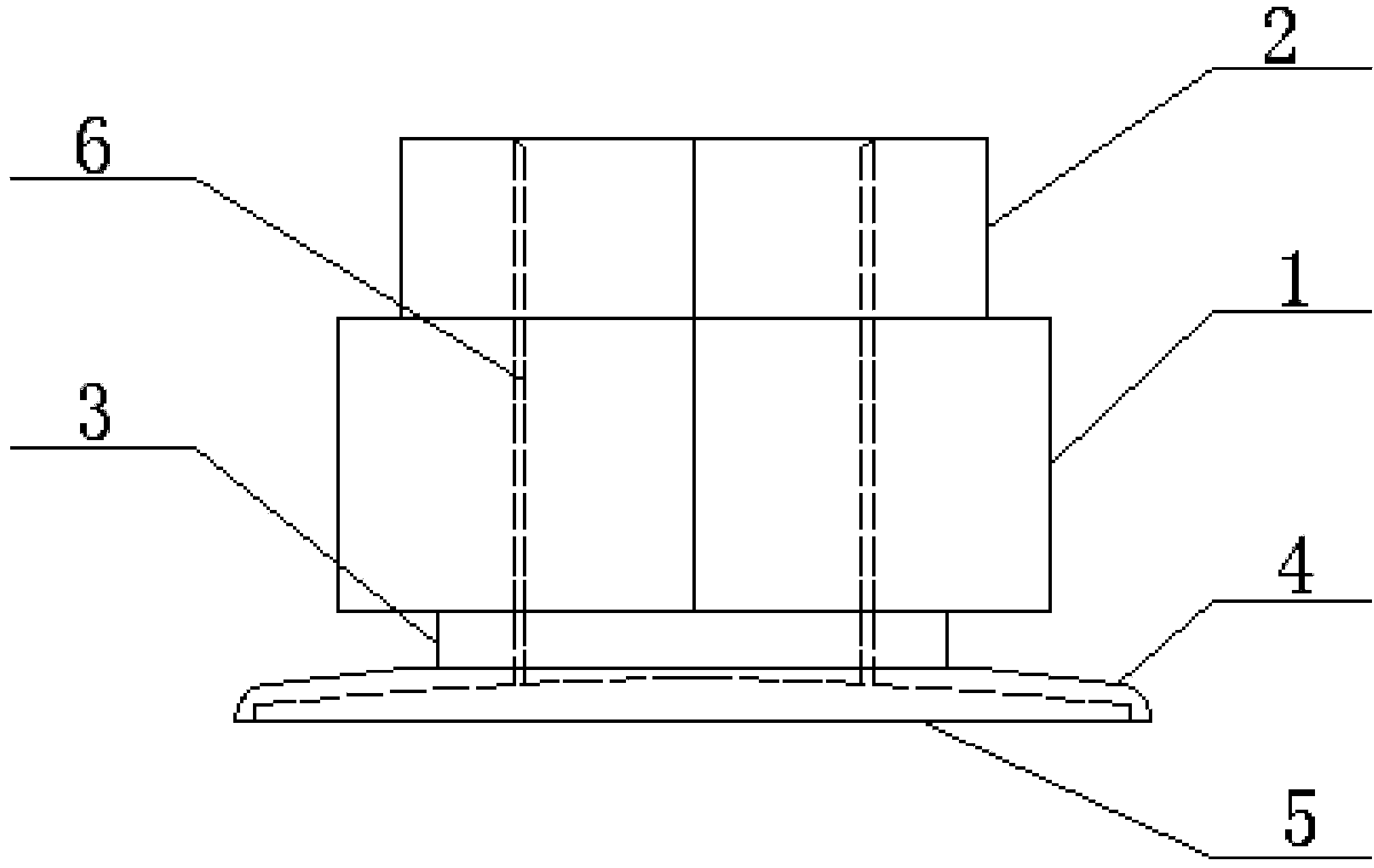

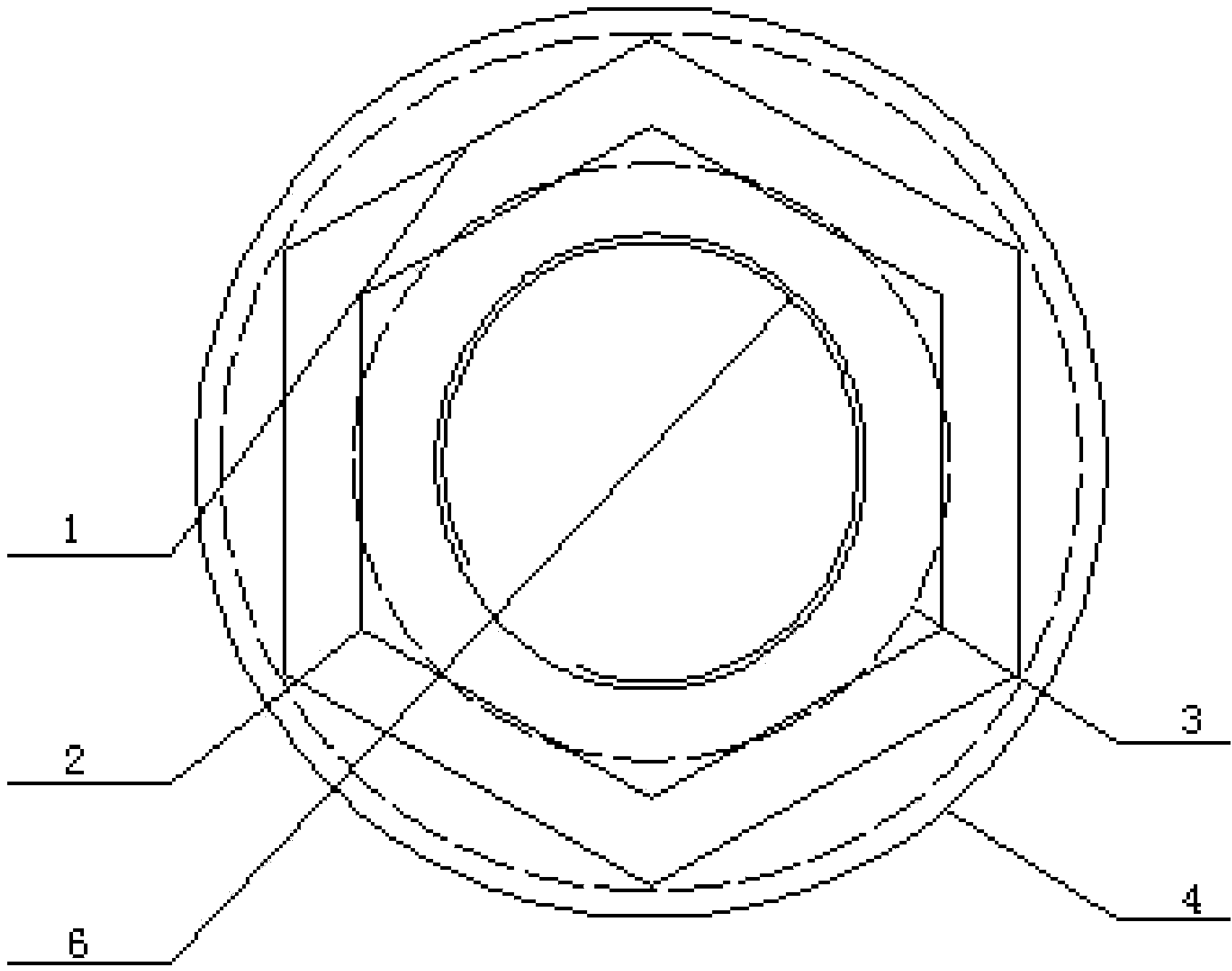

[0012] Embodiment of the present invention: a kind of nut, as attached Figure 1-2 As shown, there is an integrally formed nut body, the nut body includes a first nut 1, and the second nut 2 is located above the first nut 1, and the outer diameter of the second nut 2 is smaller than the outer diameter of the first nut 1 during production , a transition cylinder 3 is provided at the lower part of the first nut 1, the outer diameter of the transition cylinder 3 is smaller than the diameter of the inscribed circle of the first nut 1, and at the bottom of the transition cylinder 3 is an outwardly diffused horn-like structure The mounting piece 4, the lower bottom surface 5 of the mounting piece 4 is an inwardly concave arched surface, and a threaded through hole 6 with an oval structure is arranged in the nut body. Its threaded holes of the nuts currently used are circular holes, and the circular threaded holes only need to be tightened on the pegs with a little force during the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com