Locking screw

A screw and anti-loosening technology, applied in the direction of screws, nuts, bolts, etc., can solve the problems of increasing manufacturing costs and inapplicability, and achieve the effects of increasing friction, saving manufacturing costs, and increasing positive force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

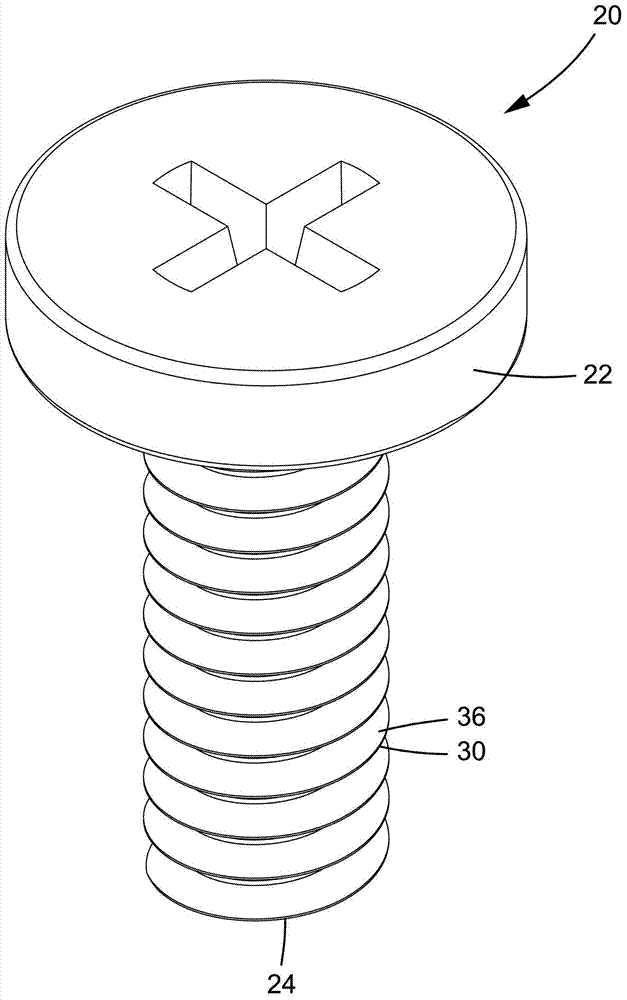

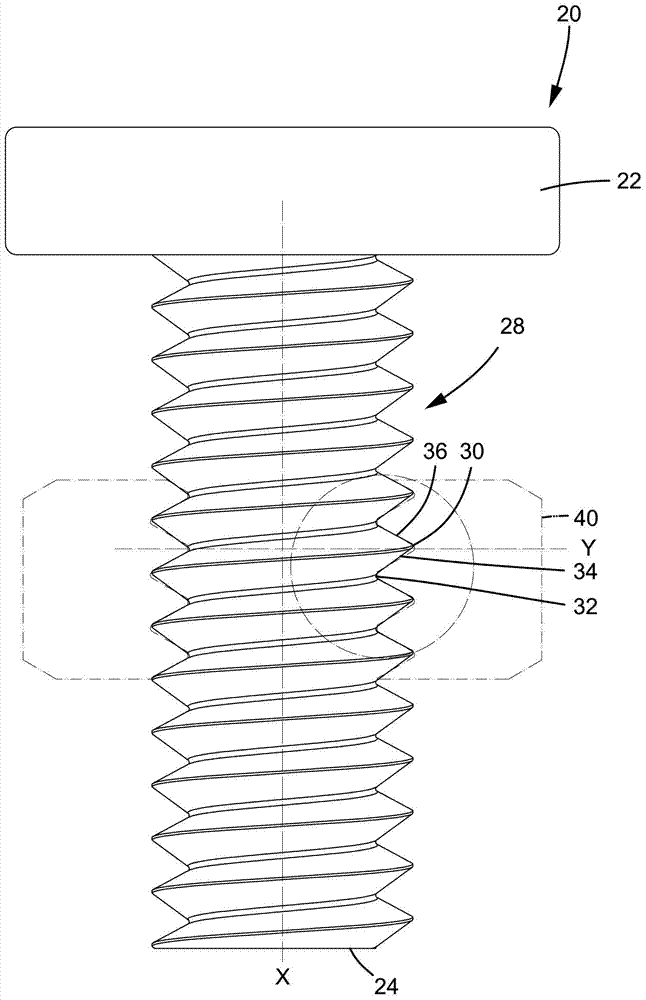

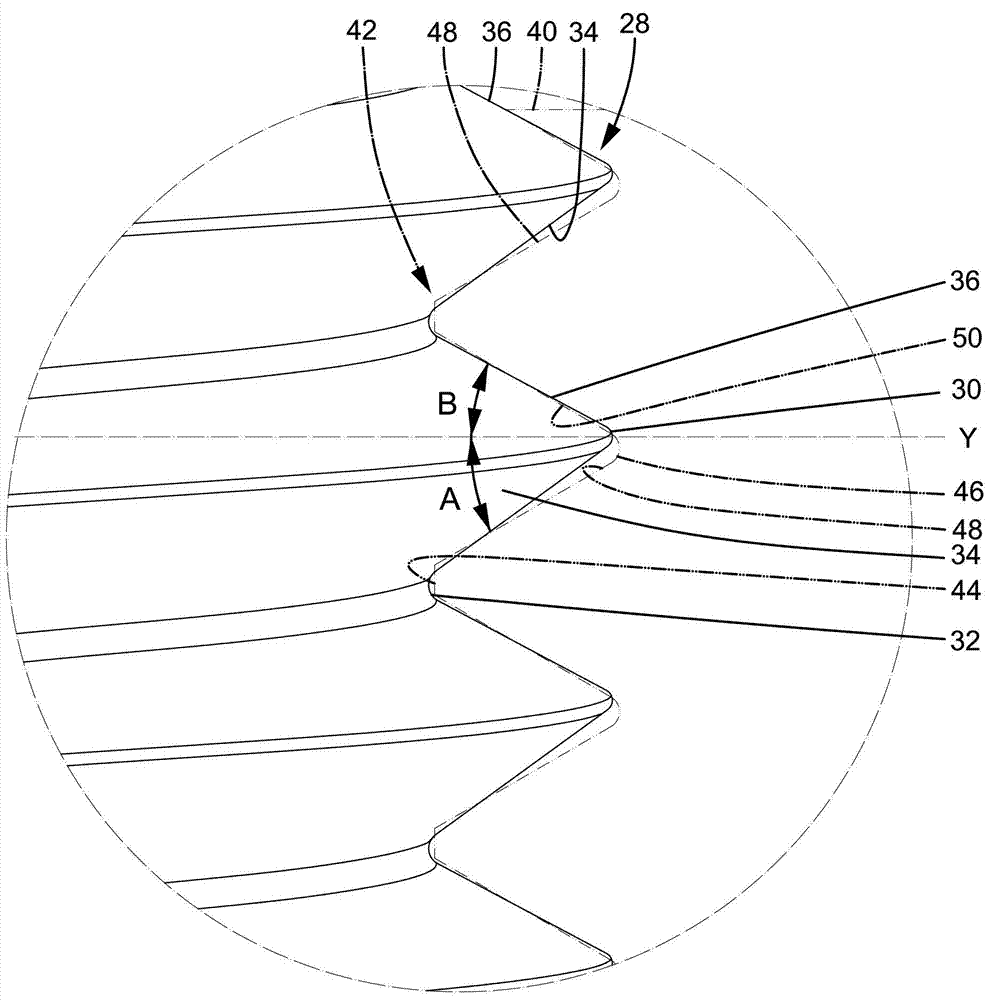

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] All of the following drawings are only for the convenience of explaining the basic teaching of the present invention. In the accompanying drawings, the number, position, relationship, and extension of the elements constituting the preferred embodiment will be described. After reading and understanding the teaching of the present invention The associated change implementation is within the skill of the industry. In addition, modification of precise dimensions and dimensional ratios to meet specific strength, weight, strength, and similar requirements is within the skill of the art upon reading and understanding the teachings of this invention.

[0015] The same or similar elements are marked with the same reference numerals in different drawings; and similar terms are only provided for viewers to refer to the structures in the drawings,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com