Apparatuses for reducing angular velocity of protective shells associated with protective headwear

A headgear, angular velocity technology, used in helmets, applications, eye surgery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

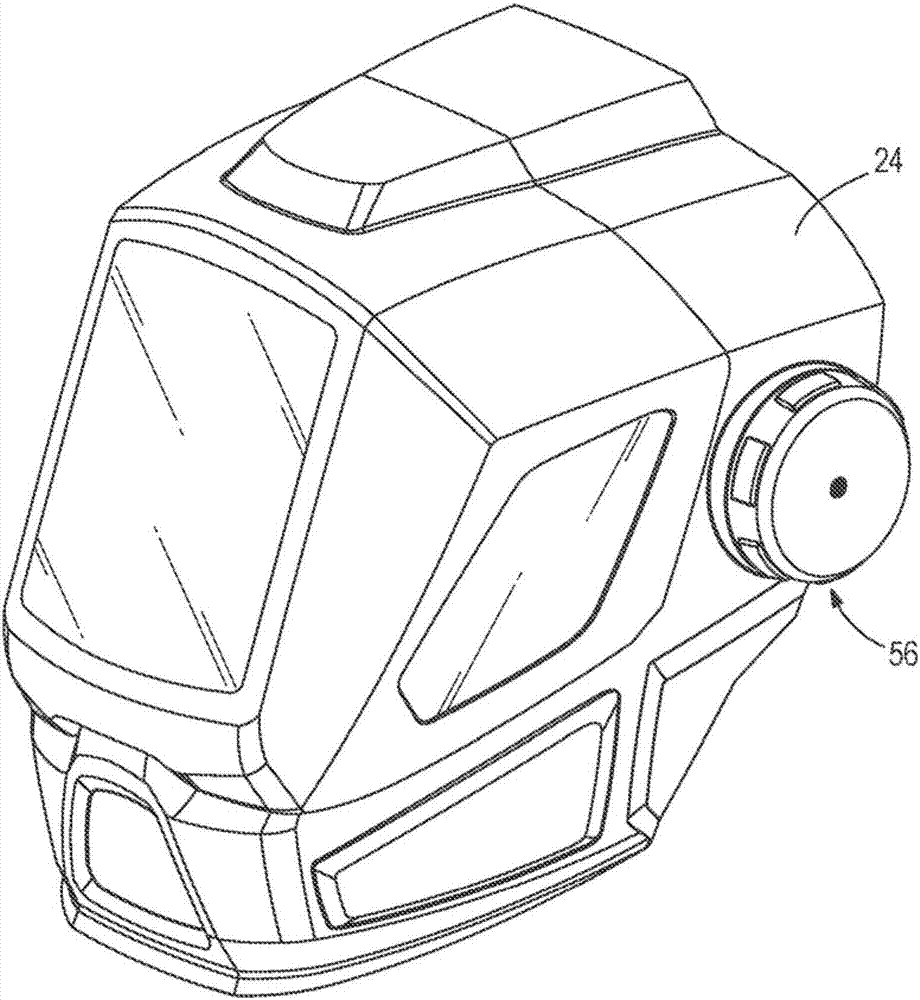

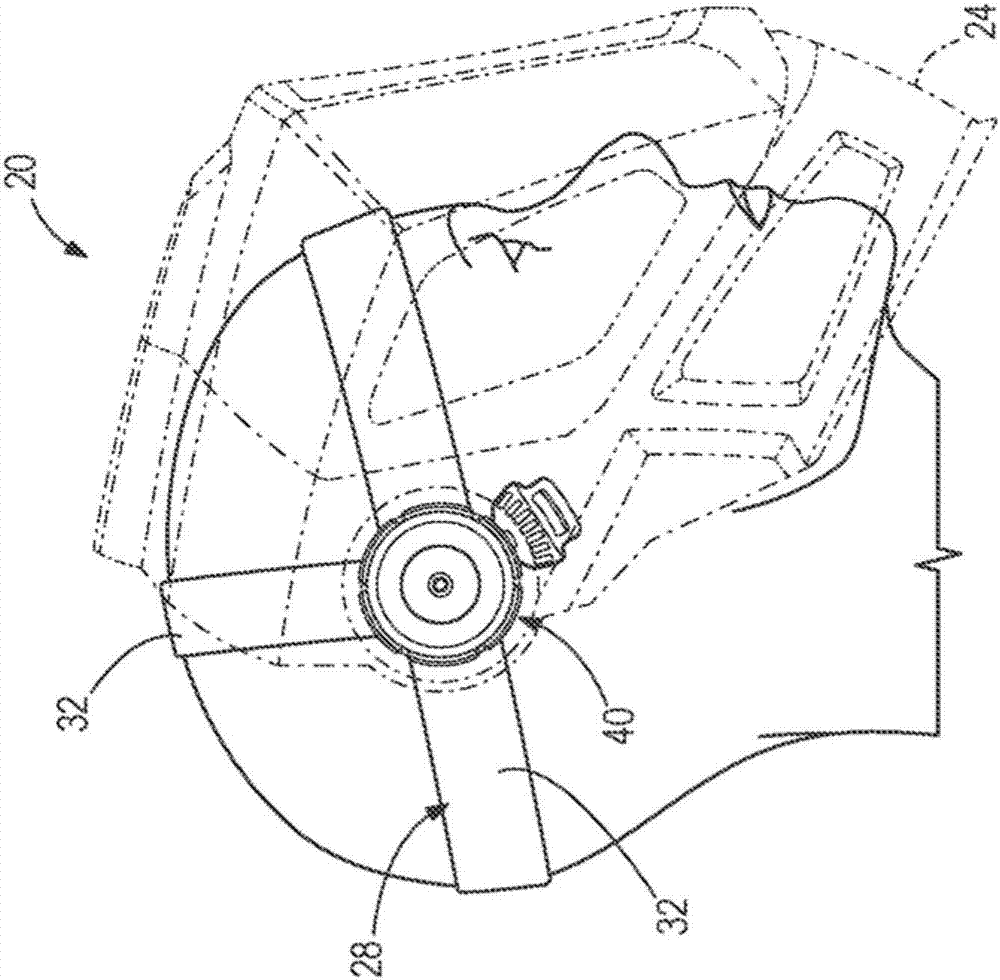

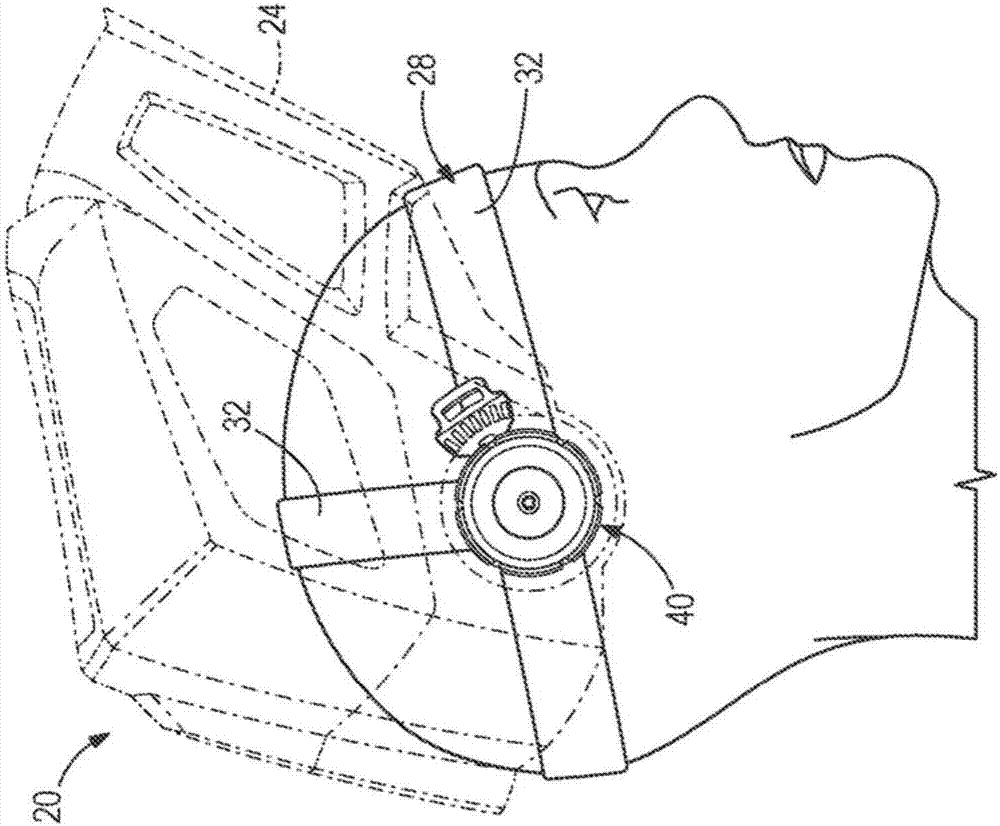

[0056] A user needs to wear the protective headgear 20 in various environments in an attempt to provide protection to the user's head. Protective headgear 20 typically has more weight than a typical baseball cap or other non-protective headgear 20, thus putting stress on the user's neck. There are many types of protective headgear 20 including, but not limited to, hard hats, welding helmets, grinding helmets, and the like. Some of the protective headgear 20 include movable parts that can apply additional stress to the user's neck. For example, during movement of the component and / or when movement of the component ceases, increased stress may be applied to the user's neck to initiate movement of the component. One example of protective headgear 20 that includes moving parts is a welding helmet 20 . For the purpose of illustrating at least some of the principles of the present disclosure, welding helmet 20 will be shown and described. However, the illustration and description...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com