Elastic terminal

A technology of elastic terminals and elastic arms, which is applied in the field of elastic terminals, can solve the problems of large space occupation, permanent deformation contact resistance, and abnormal contact, etc., and achieves good contact stability, improved product performance, and small space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

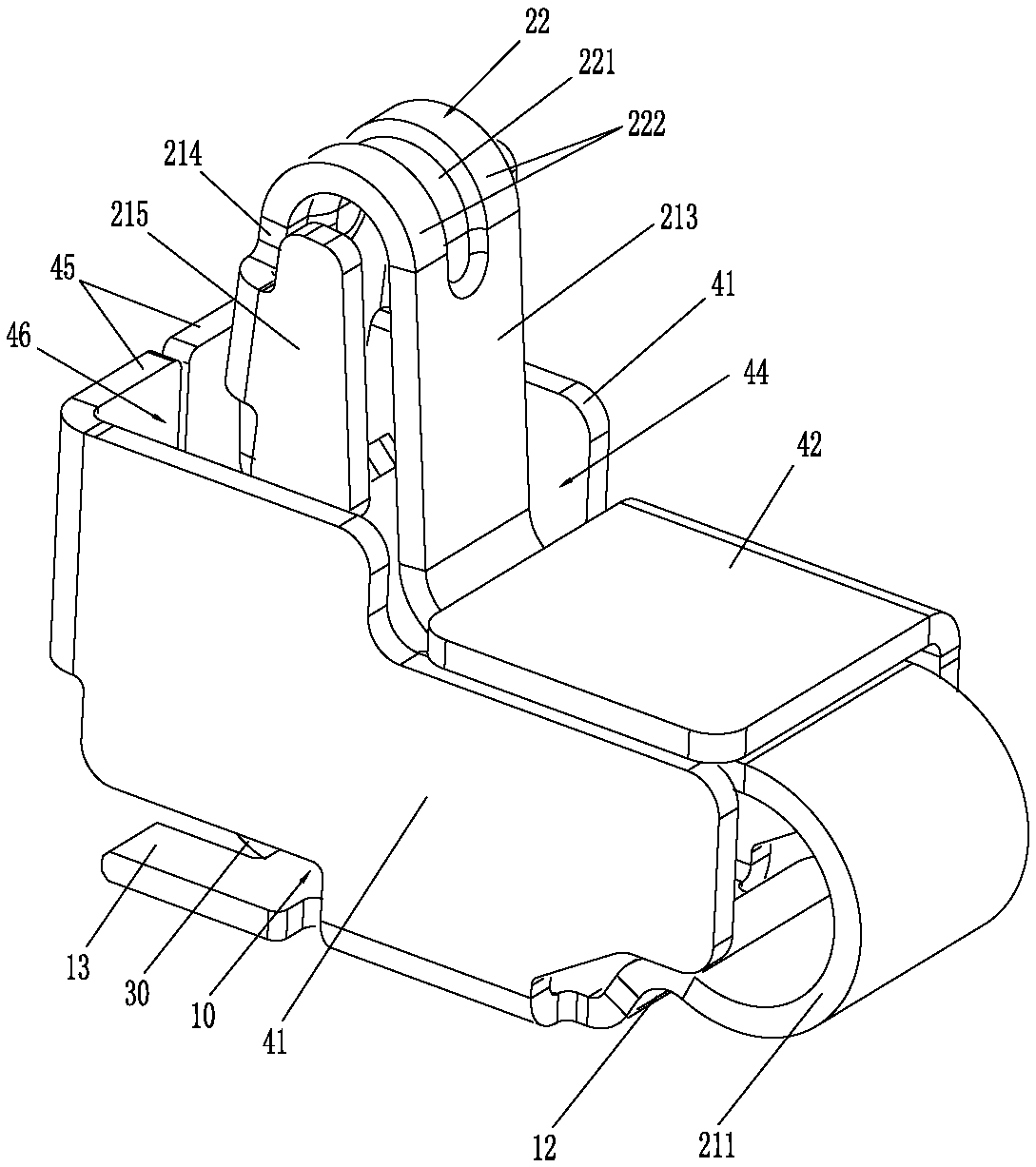

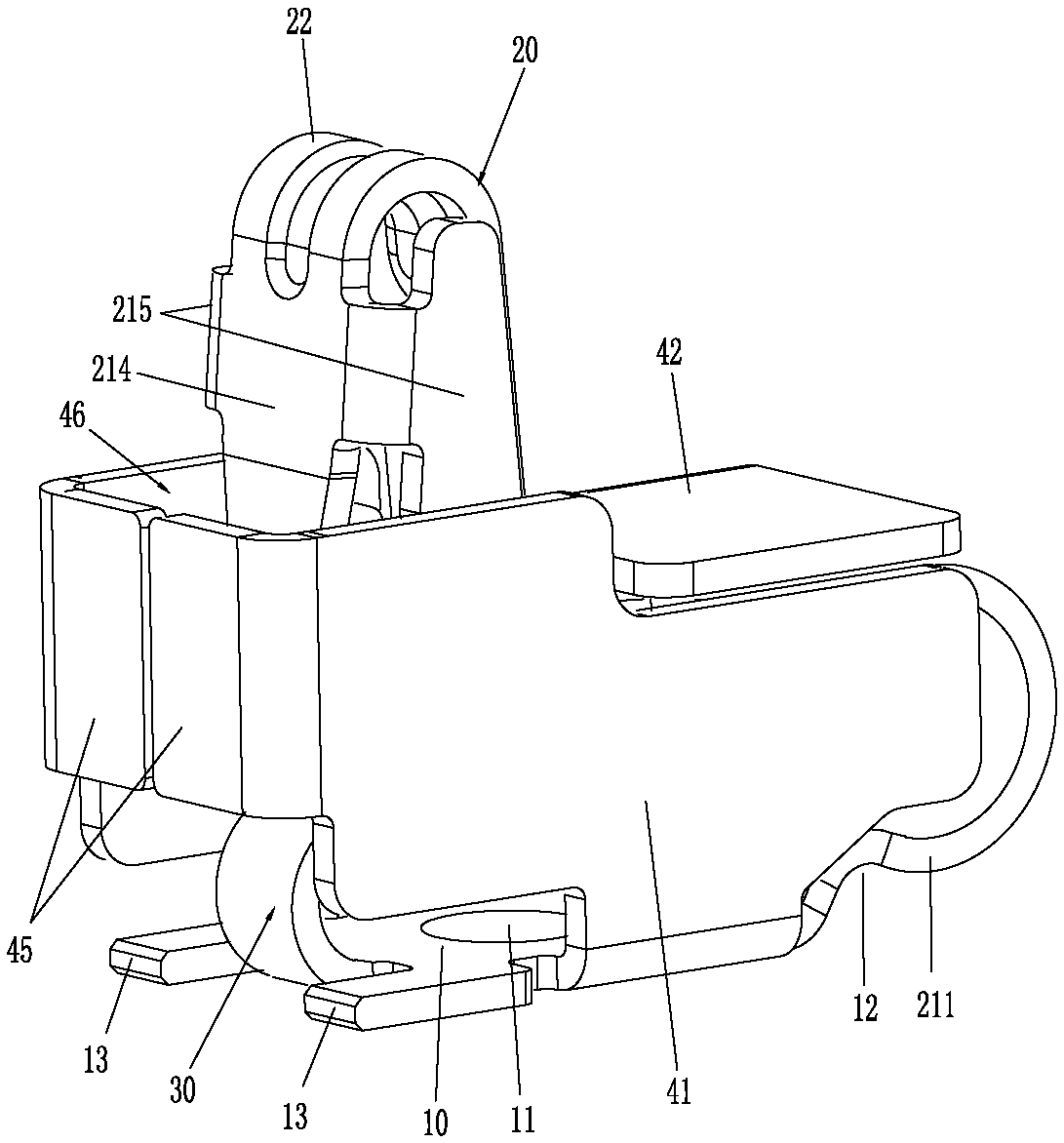

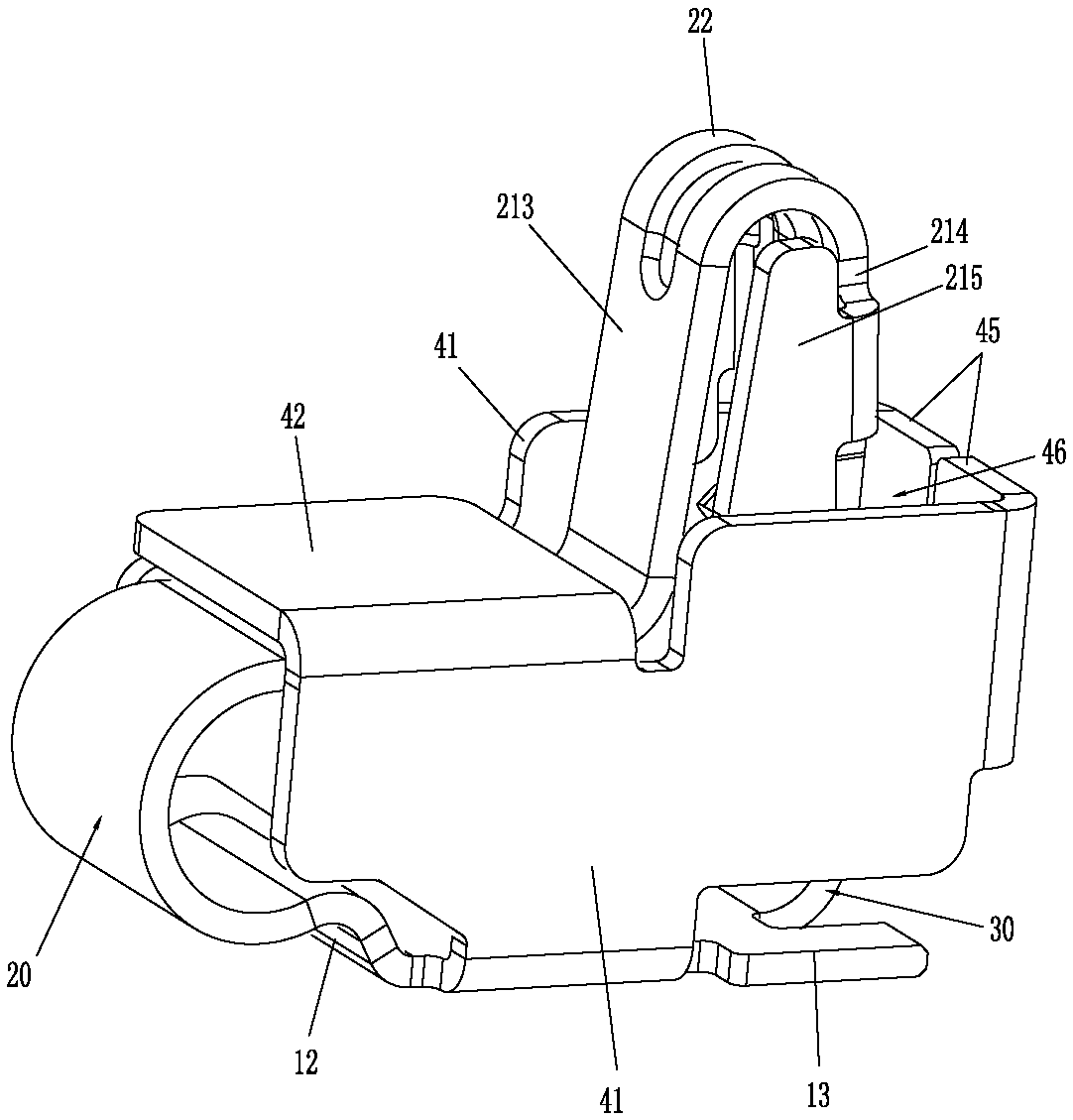

[0046] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the embodiment of the present invention. This kind of elastic terminal includes a welding base 10, a contact elastic piece 20 and a supporting elastic piece 30; this kind of elastic terminal is equivalent to a connector without a plastic seat. Thin sheet metal can be punched and bent. The manufacturing cost is low. There are no plastic seats and other parts, which simplifies assembly. It occupies less space and the overall weight is lighter, which is more in line with the design of thinner and miniaturized electronic products. need.

[0047] Wherein, the contact elastic piece 20 includes a first elastic arm 21 and a first contact portion 22 formed on the free end of the first elastic arm 21 for electrical contact. The first elastic arm 21 is integrally bent and extended from the welding base 10 Formed and suspended above the welding base 10, a deformation space 23 is formed between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com