Stable-signal connector

A signal stabilization and connector technology, applied in the direction of connection, two-part connection device, and parts of the connection device, etc., can solve the problems of small size and thinness of the shrapnel, affecting the stability of the data transmission of the connector, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

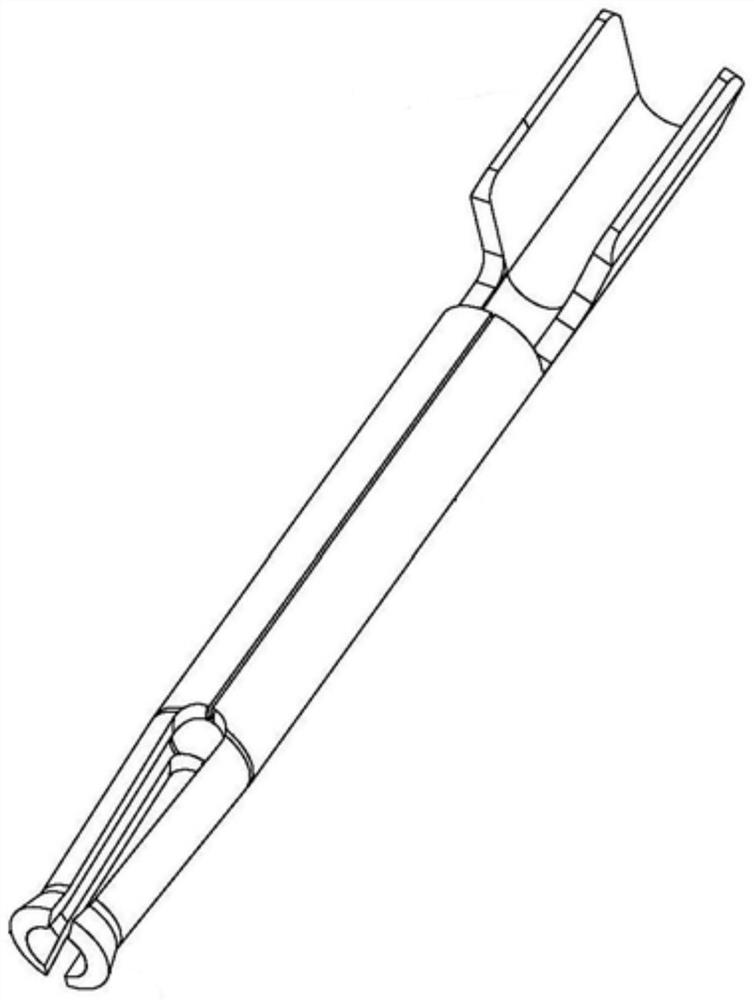

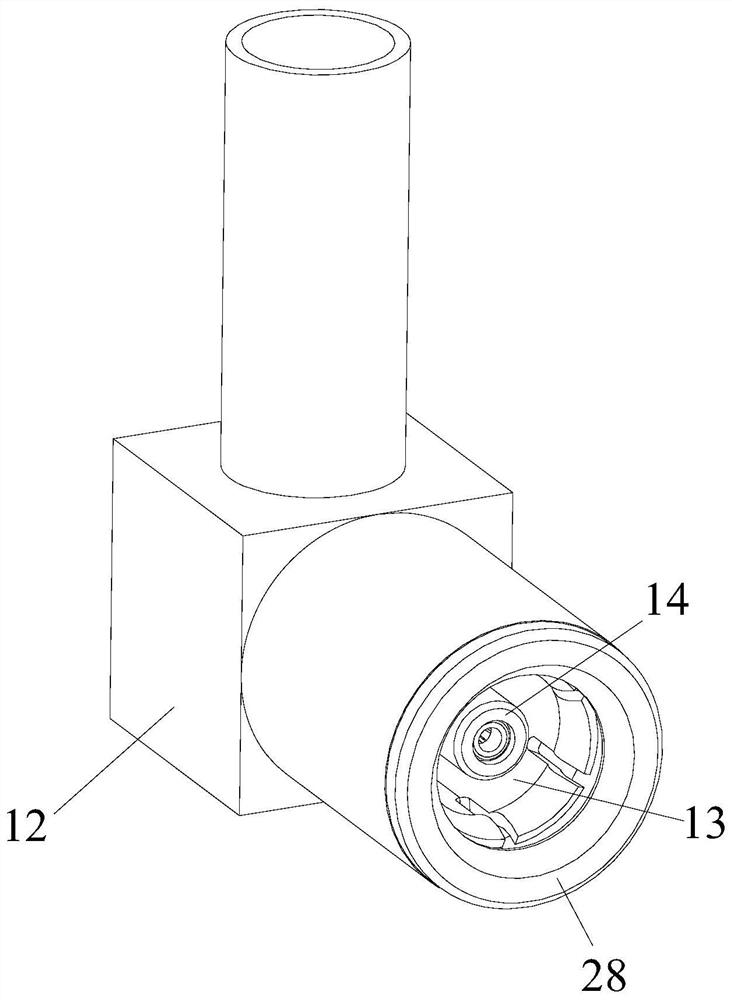

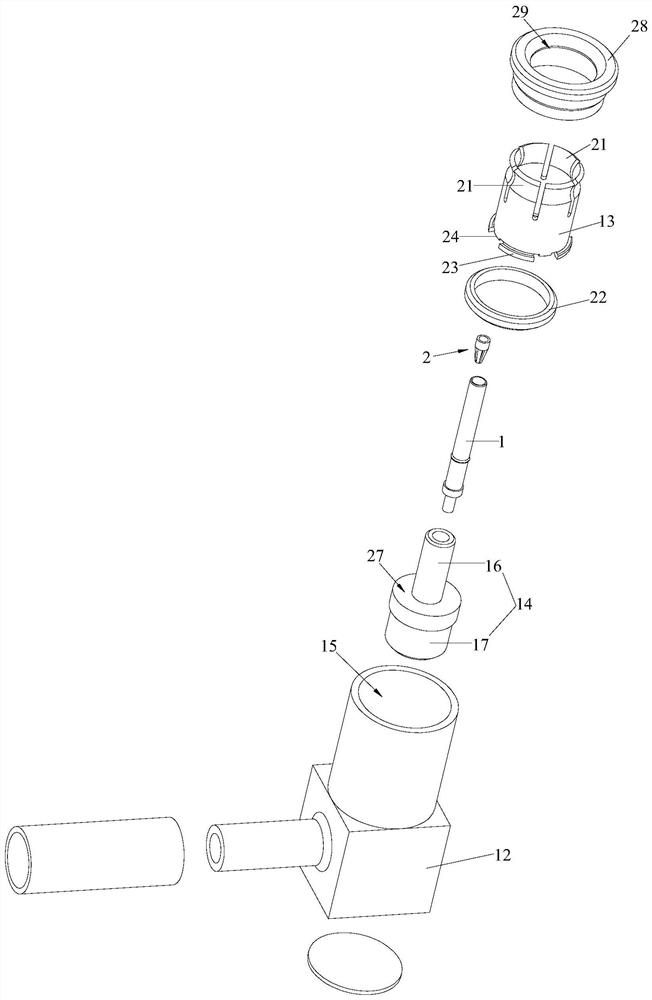

[0037] This embodiment provides a stable signal connector, such as Figure 2 to Figure 8 As shown, it includes a plastic seat 12, a metal outer cylinder 13 inserted in the plastic seat 12, an insulating seat 14 disposed in the metal outer cylinder 13, and a metal terminal assembled in the insulating seat 14. The metal outer cylinder 13 1. The insulating seat 14 and the metal terminal are arranged coaxially. The plastic seat 12 is provided with a docking hole 15. The front ends of the metal outer cylinder 13, the insulating seat 14 and the metal terminal are all exposed in the docking hole 15. The metal terminal includes The metal sleeve 1 and the claw spring 2, the claw spring 2 is used to clamp the external connection terminal, the metal sleeve 1 is provided with a cavity 3, and the claw spring 2 is assembled in the cavity 3; The claw spring 2 includes a support portion 4 and a clamping portion connected to the support portion 4 , and the outer periphery of the support portio...

Embodiment 2

[0050] This embodiment provides a stable signal connector, such as Figure 14 , Embodiment 2 On the basis of Embodiment 1, the outer wall of the insulating seat 14 is provided with axial ridges 18, and the outer walls of the upper insulating part 16 and the lower insulating part 17 are provided with a number of axial ridges 18. The axial ridges 18 are arranged at equal intervals, and the axial ridges 18 are arranged along the axial direction of the upper insulating portion 16 and the lower insulating portion 17 . Specifically, the high-frequency performance of this embodiment can be improved by providing the axial convex strips 18 with intervals between them.

Embodiment 3

[0052] This embodiment provides a stable signal connector, such as Figure 15 , Embodiment 3 On the basis of Embodiment 1, transverse ribs 19 are set on the outer wall of the insulating seat 14, and the outer walls of the upper insulating part 16 and the lower insulating part 17 are protrudingly provided with several transverse ribs 19, and several transverse ribs 19 are provided. The strips 19 are arranged at equal intervals, and the transverse convex strips 19 are arranged along the circumference of the upper insulating portion 16 and the lower insulating portion 17 , that is, the transverse convex strips 19 are arranged coaxially with the upper insulating portion 16 and the lower insulating portion 17 . Specifically, the high-frequency performance of this embodiment can be improved by arranging the transverse ribs 19 with intervals between the transverse ribs 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com