Impeller, blade of the impeller, and vertical axis wind power generator using the impeller

A technology of wind power generators and vertical shafts, applied to wind power generators, wind power generators at right angles to the wind direction, motors, etc., which can solve the problems of high wind power required for start-up, high work efficiency, and low power generation efficiency, so as to improve work efficiency , reduce wind resistance, high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

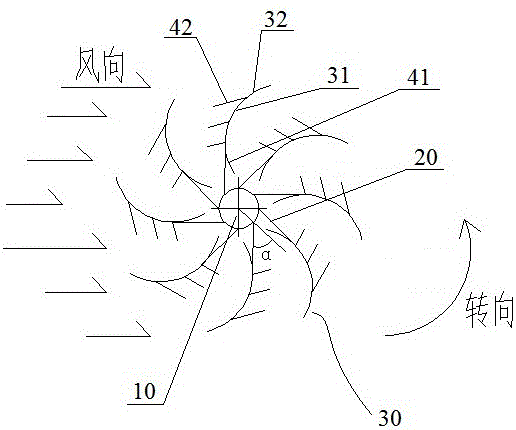

[0017] An example of an impeller in the present invention is figure 1 Shown is an impeller of a vertical axis wind power generator, including a shaft 10 and blades 30 . The blades 30 extend along the axial direction of the rotating shaft 10 and are fixed on the rotating shaft 10 through corresponding blade support rods 20 . The cross-section of each blade 30 perpendicular to the rotating shaft 10 is arc-shaped, and forms an S-shape together with the blades on the opposite side. When working, the impeller follows the figure 1 set in the way of figure 1 Rotate in the direction shown by the arc-shaped arrow, the axial direction of the rotating shaft 10 is perpendicular to the wind direction, the air flow forms a power area below the rotating shaft 10, and forms a resistance area above the rotating shaft 10.

[0018] The outer end of each blade 30 away from the center of rotation is inclined towards a side away from the rotation direction of the blade 30 , so that the blade 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com