Polyurethane for bearing and preparation method thereof

A polyurethane and bearing technology, which is applied in the field of polyurethane for bearings and its preparation, can solve the problems of permanent deformation of polyurethane and affect the service life of polyurethane, and achieve the effects of good resilience, prolonging service life and improving structural density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

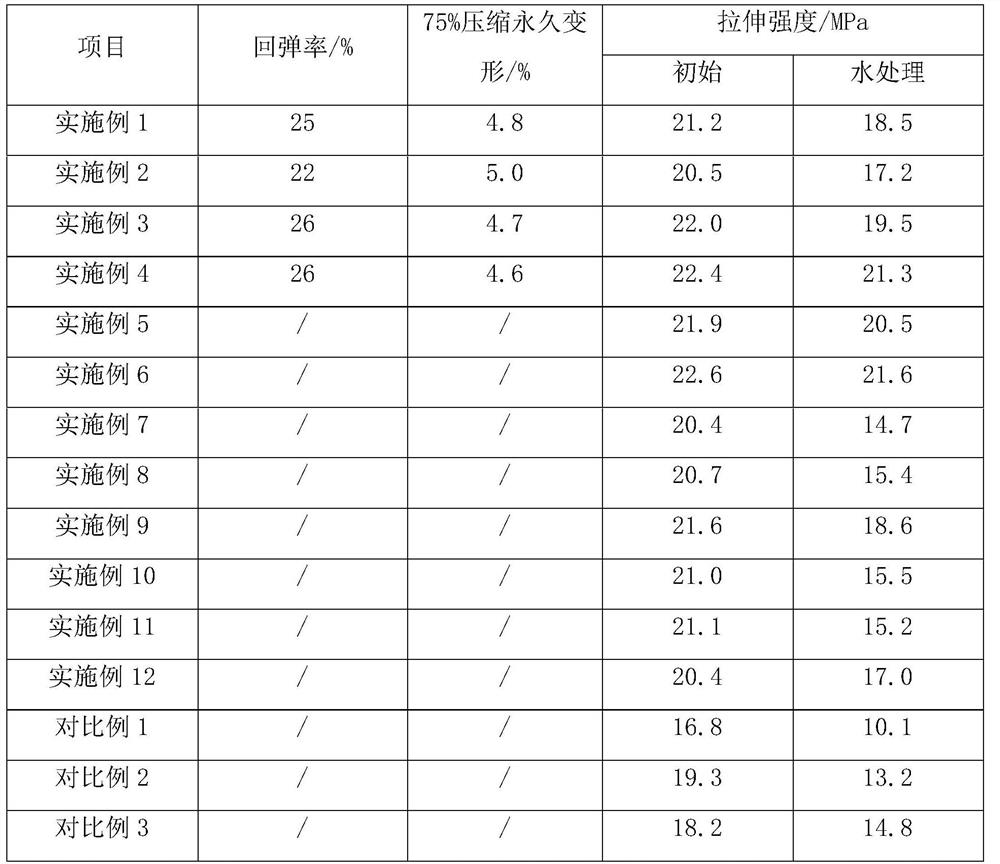

Examples

preparation example 1

[0045] Preparation Example 1: Modified four-needle zinc oxide whiskers were prepared by the following method:

[0046] Weigh 10 g of four-needle zinc oxide whiskers and place them in 200 g of aminopropyltriethoxysilane to disperse evenly, then dry and disperse until the four-needle zinc oxide whiskers do not agglomerate and adhere to each other to obtain a finished product; four The diameter of the central body of the needle-shaped zinc oxide whisker is 1 μm, and the length of the needle-shaped body is 20 μm.

[0047] Preparation example of mesoporous silica

preparation example 2

[0048] Preparation Example 2: Mesoporous silica was prepared by the following method:

[0049] Weigh 490 mg of cetyl trimethyl ammonium chloride, 15 mg of 99% absolute ethanol, and 0.22 mg of triethanolamine together into 400 mL of deionized water, and stirred at 84 °C for 0.6 h, and then added to 1 mL / mL of deionized water. Add 2.6 mL of tetraethyl orthosilicate at the speed of min, stir evenly, stir at 84 °C for 6 h, collect the product by centrifugation for 15 min, wash with methanol 5 times, and then disperse in an acidic methanol solution (containing 2 mL of HCl 100mL methanol) was condensed and refluxed for 3 times, the temperature of the condensed reflux was 66 ° C, and the time was 14h. After the washing was complete, the semi-finished product was collected by centrifugation, then washed with methanol twice, and then washed with deionized water for 3 times, and then vacuum freeze-dried 12h, the finished mesoporous silica was obtained.

[0050] Preparation example of e...

preparation example 3

[0052] Preparation Example 3: The epoxy resin liquid was prepared by the following method:

[0053] Weigh 60kg of epoxy resin, 20kg of curing agent, 8kg of diluent, and 1.6kg of leveling agent, mix and stir to obtain the finished epoxy resin liquid; epoxy resin model E44; curing agent is T-31 curing agent; diluent is Anhydrous ethanol, the mass fraction of anhydrous ethanol is 99%; the leveling agent is HR-6031 wetting and leveling agent (polyether modified polysiloxane polymer).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com