Precise rail docking device of self-walking trolley conveying machine

A self-propelled trolley and docking device technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of falling off, damage to the movable track, easy loosening, etc. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

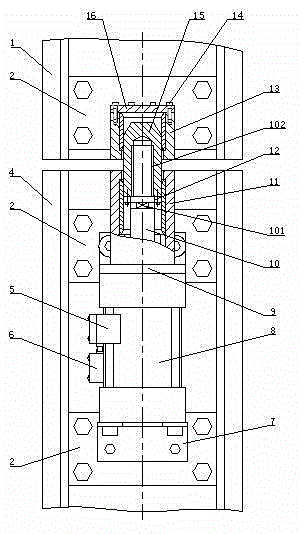

[0007] see figure 1 , the self-propelled trolley conveyor track precision docking device of the present invention includes a movable track 1, a fixed track 4 and a rail bar 15, and also includes a cylinder fixing seat 7, a cylinder 8, a cylinder end seat 9, a fixed end positioning composite sleeve 11, and an anti-loosening plate 12. The movable end positioning composite sleeve 13, the end cover 16 and three positioning seats 2, the upper limit switch 5 and the lower limit switch 6 are installed on the cylinder 8, and the tenon 101 and external thread are provided on the extension shaft 10 of the cylinder 102, the movable track 1 is equipped with a positioning seat 2, the movable end positioning compound sleeve 13 is mounted on the positioning seat 2 of the movable track 1, and the end cover 16 is mounted on the movable end positioning compound sleeve with hexagon socket head cap screws 14 13, a positioning seat 2 is installed on the upper and lower parts of the fixed rail 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com