Water-cooled heat dissipation type pressure-resistant electronic cabin

A technology of water cooling and heat dissipation, electronic cabin, applied in cooling/ventilation/heating transformation, underwater ships, underwater operation equipment, etc., can solve the problems of not considering the heat dissipation of electrical components, small effective installation area, and not being effectively solved. , to achieve the effect of extending sustainable working time, improving heat dissipation efficiency, and improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

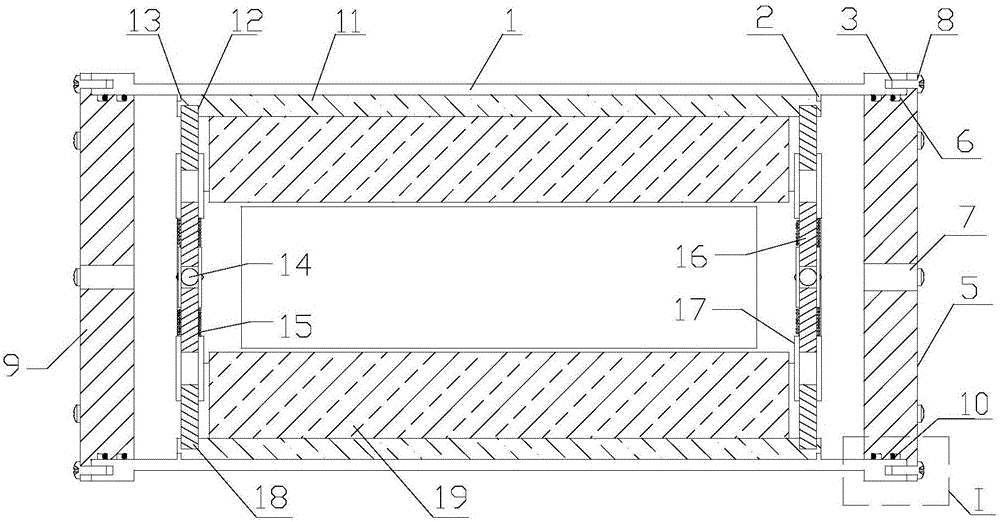

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

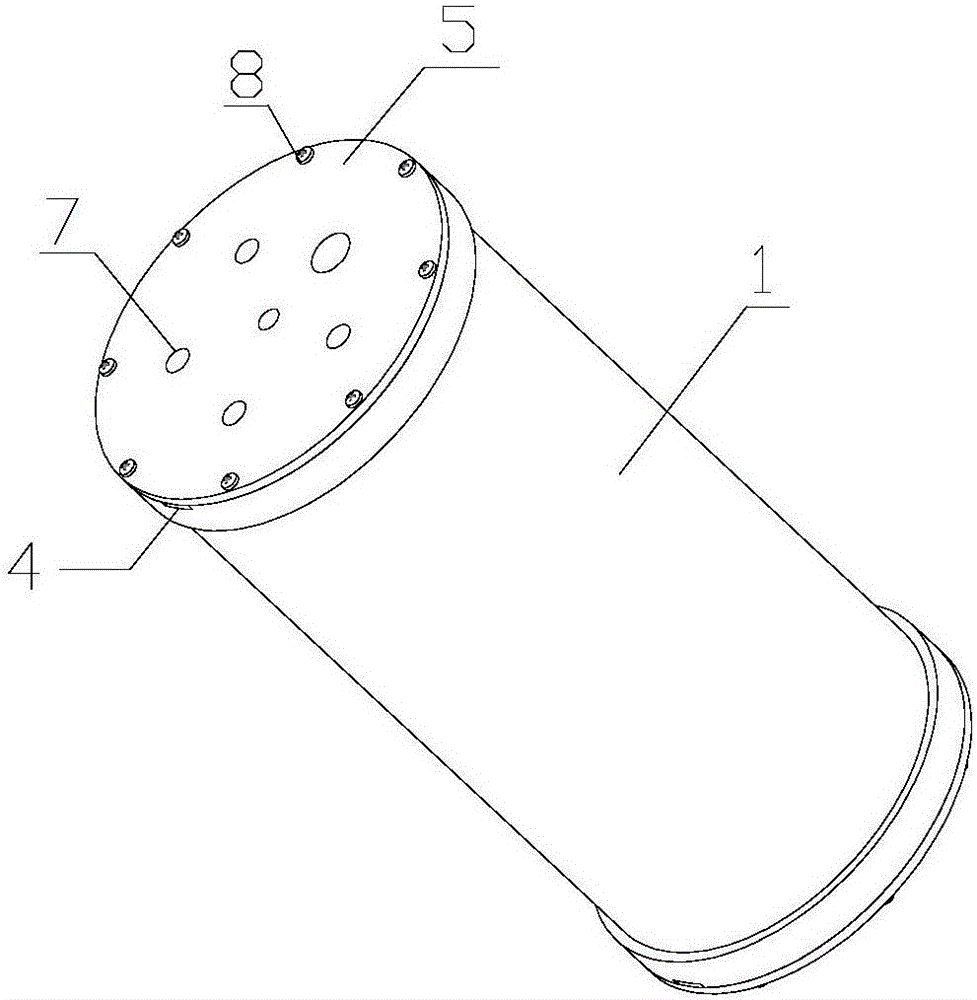

[0028] Such as Figure 1 to Figure 6 As shown, the pressure tank shell among the present invention comprises a cylindrical main cabin body 1, a cylindrical front end cover 5 and a cylindrical rear end cover 9. Flanges are left at both ends of the main cabin body 1, and eight threaded holes 3 symmetrical to the center of the axis are provided on the end surface of the flange, and two dismounting grooves 4 symmetrical to the center of the axis are provided on the end surface of the flange.

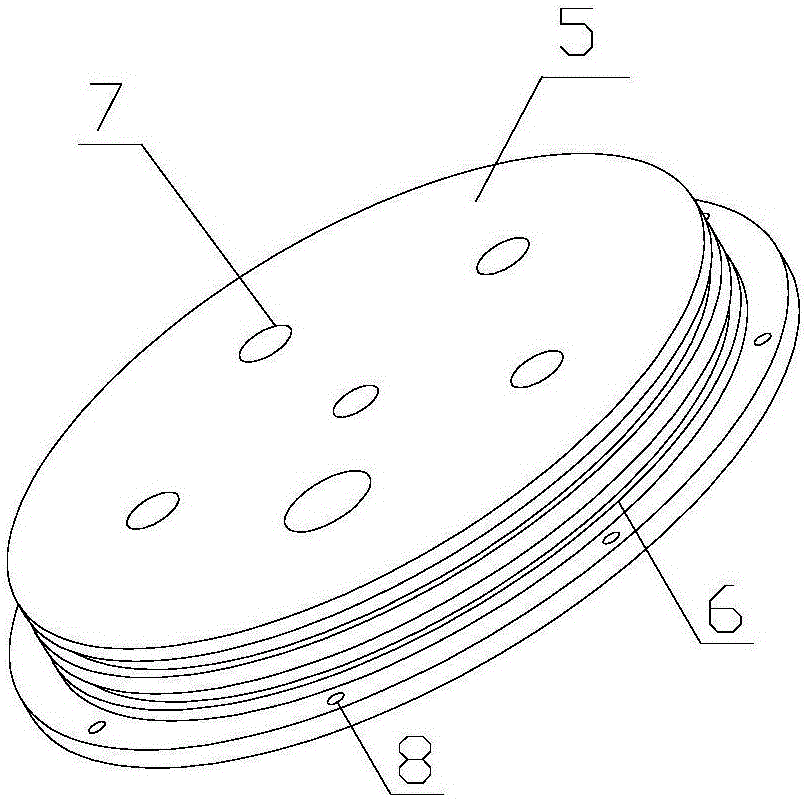

[0029] Such as figure 2 As shown, the front end cover 5 is a second-order cylindrical structure, and the outer cylindrical end surface is provided with eight circular positioning holes 8 corresponding to the main cabin body 1, and the inner cylindrical end surface is provided with a number of connectors for installing watertight cable connectors. The socket 7 has two annular seali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com