Small ring-grooved rivet with wide range and riveting method

A ring groove rivet, a wide range of technology, used in rivets and other directions, can solve the problems of easy on-site installation, small clamping range, and various types of formation, and achieve high connection strength, good anti-loosening performance, and large clamping range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

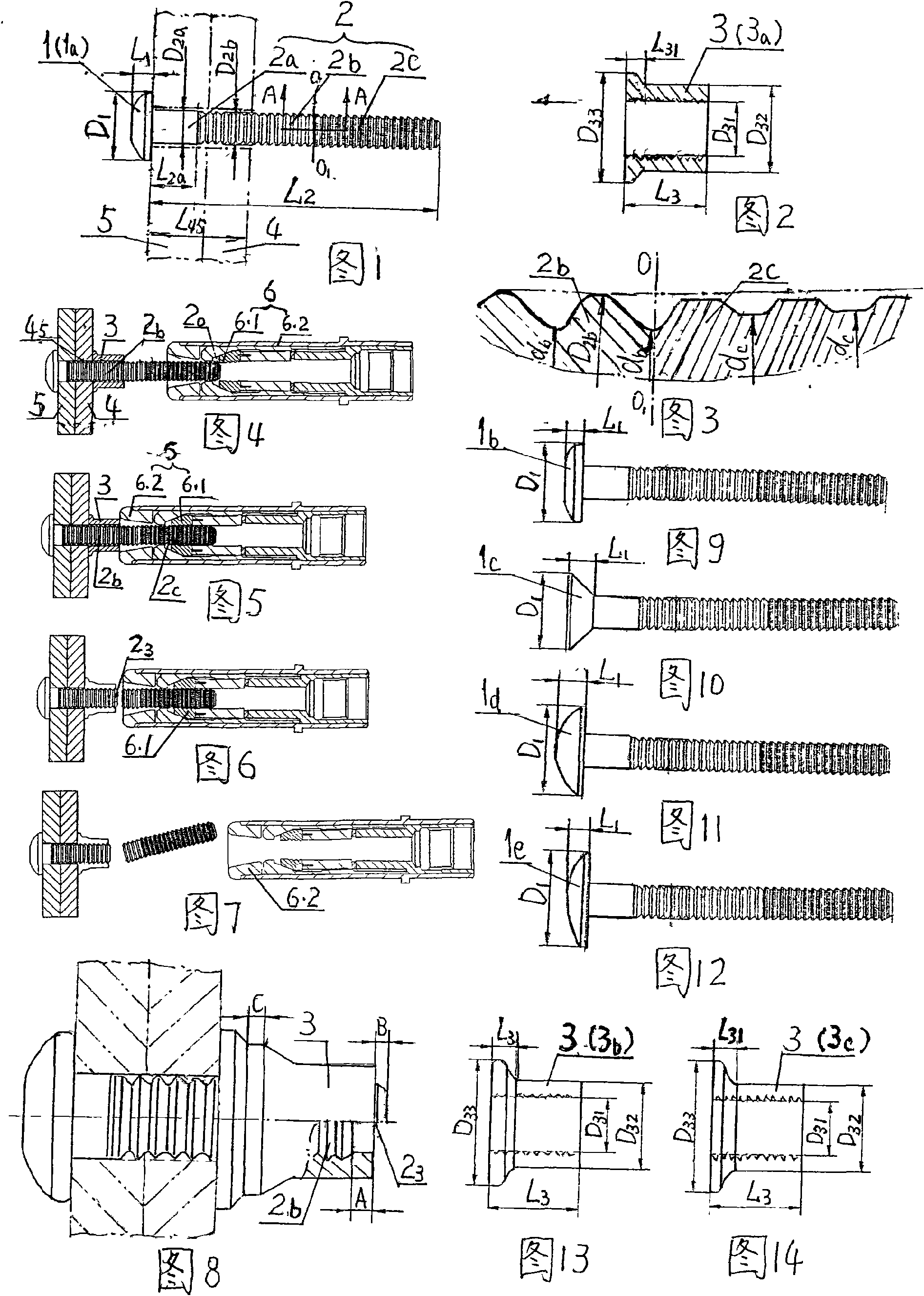

[0038] Example 1: see Figure 1 to Figure 8

[0039] See figure 1 , figure 2 , This embodiment 1 wide-range small ring groove rivet is composed of nail head 1, nail shank 2 and collar 3. Among them, the nail head 1 is a round head 1a; the collar 3 is a flange collar 3a; a , Front ring groove section 2 for extrusion fit with collar b And the rear ring groove section 2 used for riveting with the riveter at the rear end c composition. See image 3 , the diameter of the fine teeth of the front ring groove section d b Smaller than the fine tooth diameter of the rear ring groove d c .

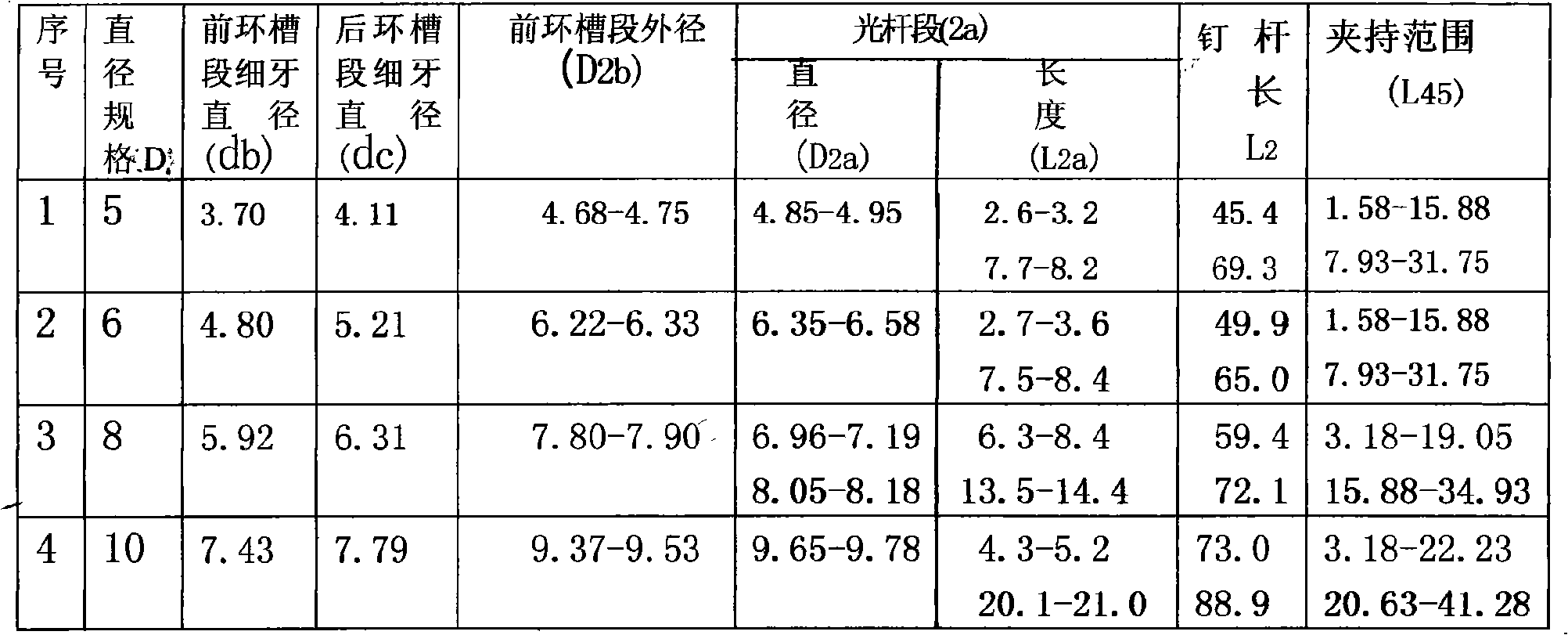

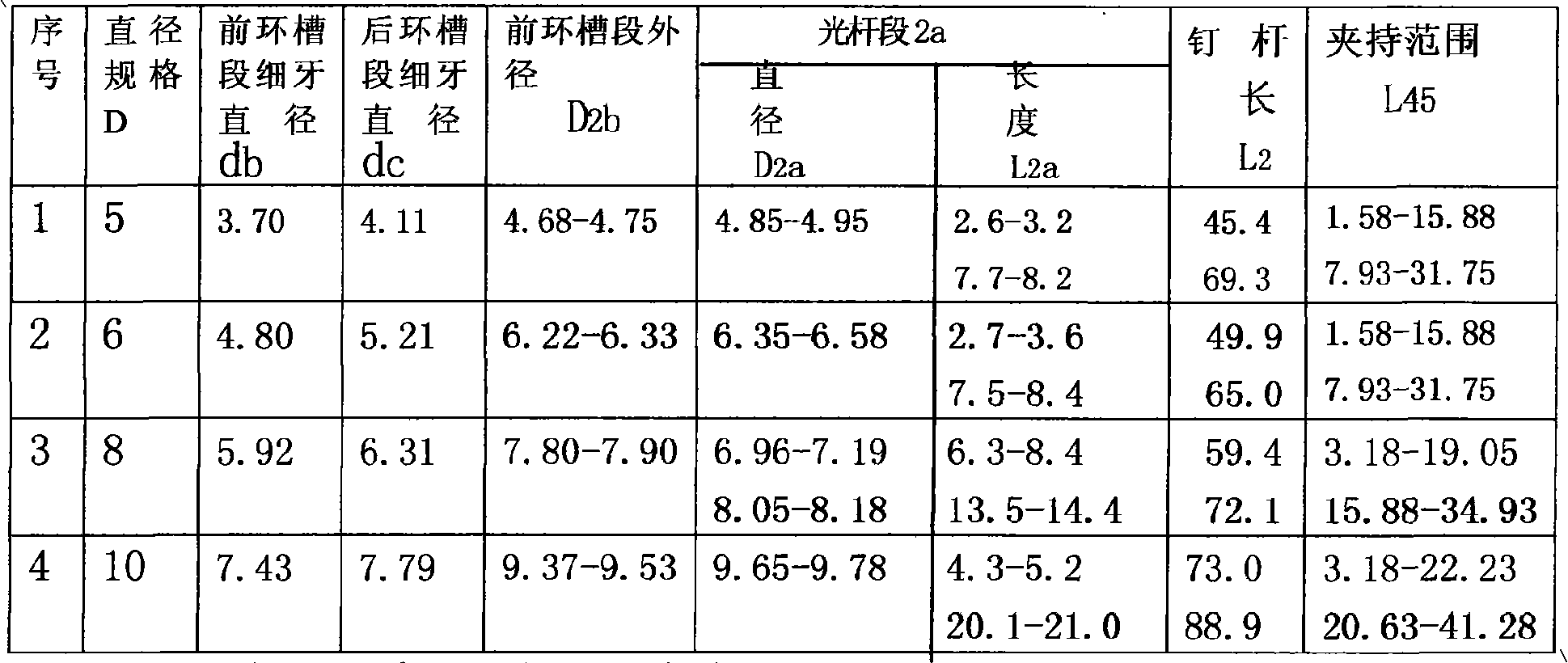

[0040] See Table 1, Table 2, Table 3, figure 1 , figure 2 and image 3 , the selected size of the wide-range small ring groove rivets in this embodiment 1 is as follows: serial number 1, diameter specification D=5mm, diameter of fine teeth of the front ring groove section d b =3.70mm is less than the fine tooth diameter d of the rear ring groove segment c =4.11; reduction ratio β=9....

Embodiment 2

[0049] Embodiment 2: The wide-range small ring groove rivet of Embodiment 2 is identical to Embodiment 1 except for the following diameter specifications and corresponding dimensions. See Table 1, when the diameter specification D is 6, 8 or 10mm, the corresponding diameter d of the fine teeth of the front ring groove section b , The diameter of the fine teeth of the rear ring groove section d c , Outer diameter D of the front and rear ring grooves bc , polished rod section diameter D 2a , the length of the polished rod section L 2a , Nail length L 2 and clamping range L 45 etc. are three groups corresponding to serial numbers 2, 3 or 4 in Table 1, and each group has seven values and value range numbers in total.

Embodiment 3

[0050] Embodiment 3: The wide-range small ring groove rivet of Embodiment 3 is identical to Embodiments 1 and 2 except for the following head types and corresponding dimensions. See Table 2, Figure 9 , Figure 10 , Figure 11 , Figure 12 , the diameter specification D is 6, 8 or 10mm, and the nail head 1 is the diameter D of the pan head 1b, countersunk head 1c, half-round head 1d or thin half-round head 1e 1b 、D 1c 、D 1d 、D 1e and thickness L 1b , L 1c , L 1d , L 1e They are the value range numbers of No. 1, No. 2, No. 3 or No. 4 in Table 2 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com