Nut anti-loosening mechanism special for railway turnout

A technology for nuts and turnouts, which is applied in the field of anti-loosening mechanism for special nuts for railway turnouts, and achieves the effects of convenient operation, reduced cost of turnouts, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

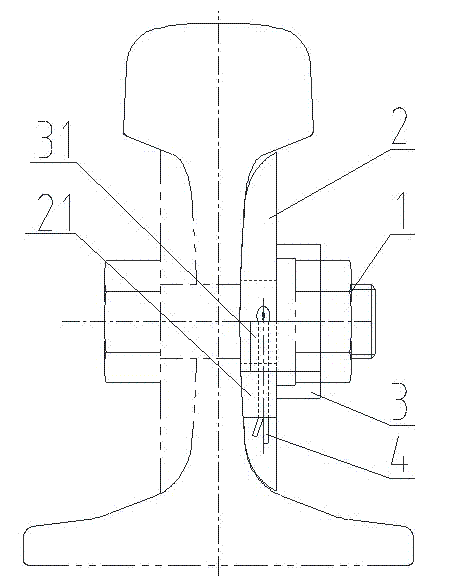

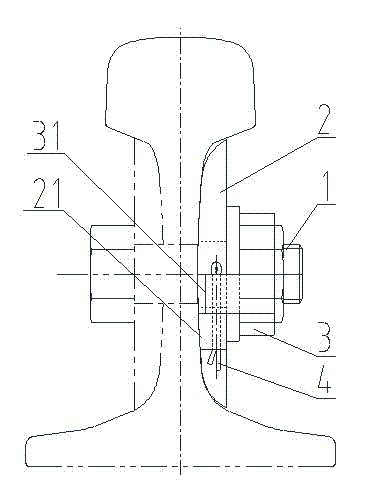

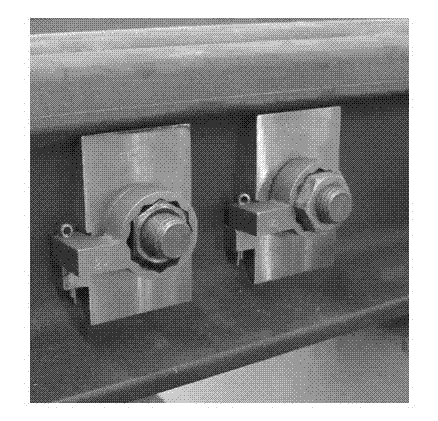

[0020] That is, the special nut anti-loosening mechanism of railway turnout is made up of rail washer 2, nut anti-rotation washer 3 and cotter pin 4. The rail washer 2 is fixedly installed on the rail waist through the bolt and nut 1, and the anti-rotation washer 3 set on the bolt and nut 1 is connected with the rail washer 2 through the cotter pin 4, thereby restricting the rotation of the nut along the loosening direction to achieve self-locking The function, by comparing the installation and fixing methods of the rail washer 2 and the anti-rotation nut, the scheme of the side connection of the single cotter pin.

[0021] It should be understood that: although the above-mentioned embodiments have made more detailed text descriptions to the design ideas of the present invention, these text descriptions are only simple text descriptions to the design ideas of the present invention, rather than limitations to the design ideas of the present invention. The combination, addition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com