Conical internal thread

An internal thread, tapered technology, applied in the direction of threaded fasteners, nuts, bolts, etc., can solve the problems of uneven load distribution, easy wear and tear of threaded parts, uneven force, etc. Alternating loads, excellent resistance to lateral vibration, resistance to wear and fatigue fracture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

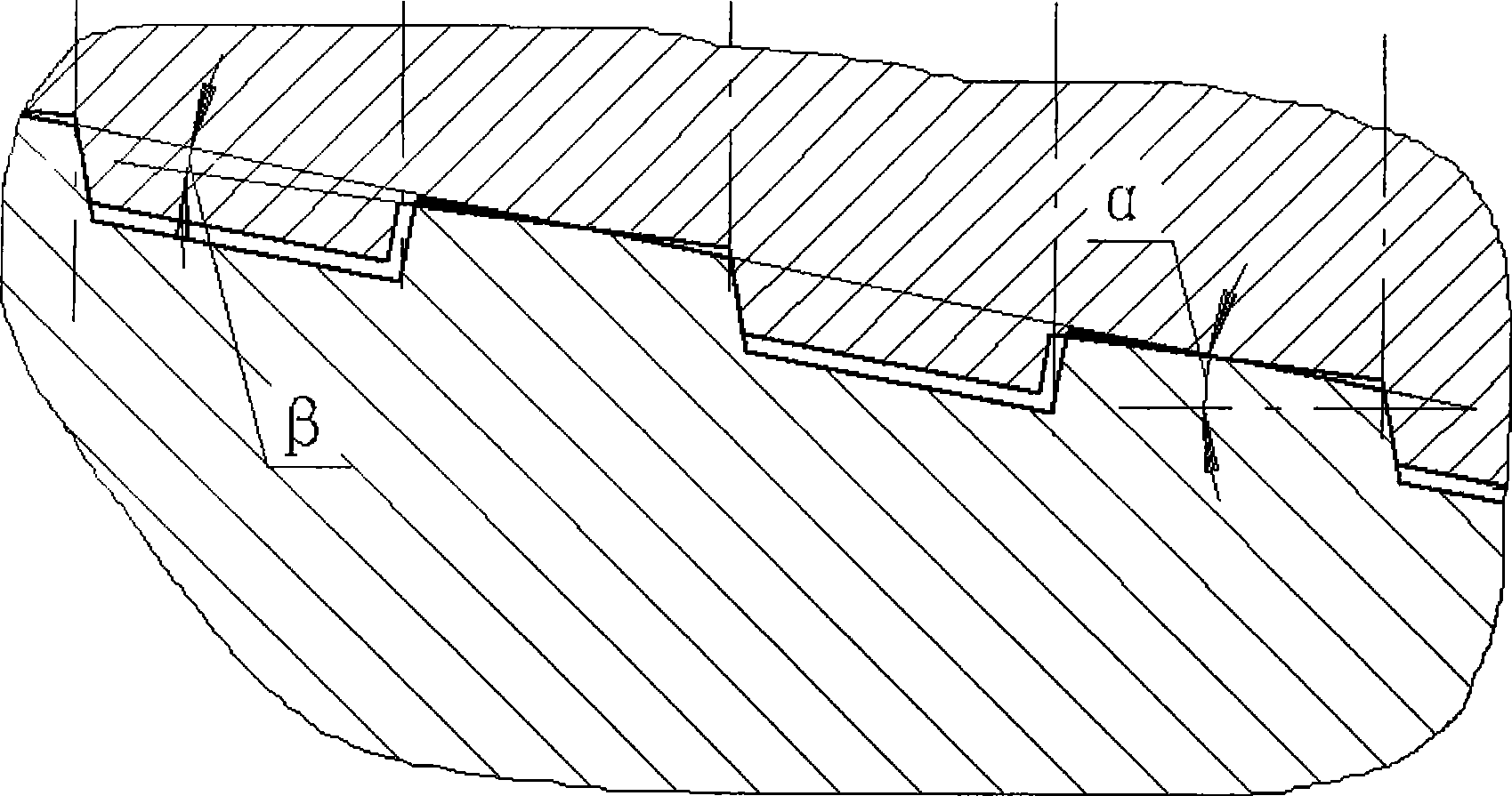

[0010] A tapered internal thread, the root between the teeth is a centering slope, the upper large-diameter end of the centering slope is a centering surface that interferes with the crest of the external taper thread, and the centering slope The included angle β with the main cone surface is 0°<β<α, and α is the inclination angle of the taper thread.

[0011] The tooth shape of the tapered internal thread is triangular, trapezoidal, or zigzag. The root between the teeth is based on the position of the crest of the external tapered thread that matches it. The large diameter end is convex inward, and the small diameter end is concave outward. Form the centering slope.

[0012] The root of the tapered internal thread forms a standard helix with an inclination angle of α at the intersection of the crest of the external tapered thread that matches it.

[0013] The internal thread adopts a double-cone structure. After the internal and external threads are matched, a tight distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com