Iron-based shape memory alloy locking bolt as well as production and application method thereof

A memory alloy, anti-loosening bolt technology, applied in the direction of bolts, screws, nuts, etc., can solve the problems of inconvenient use, change the nature of detachable connections, high cost and difficult to promote, etc., and achieve high tensile strength and anti-loosening effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

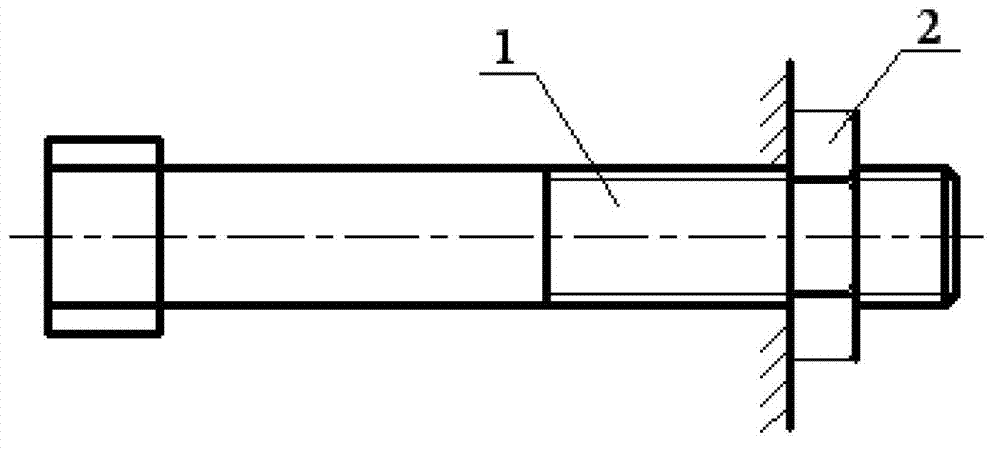

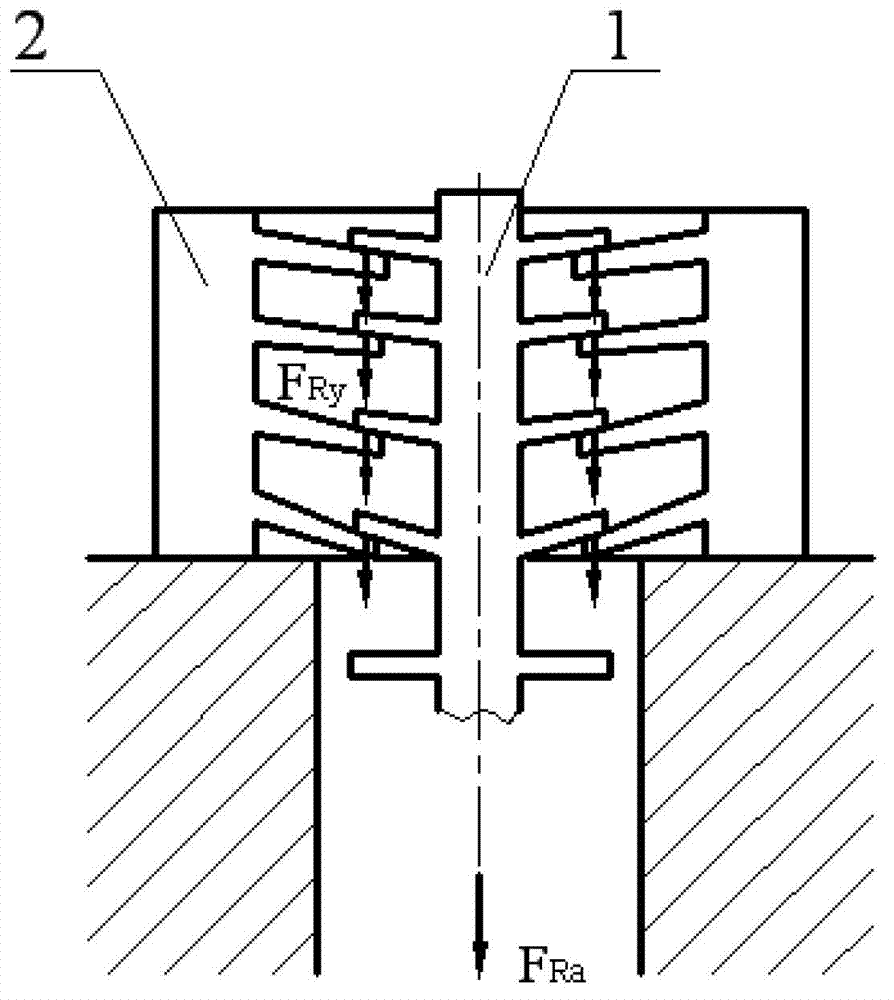

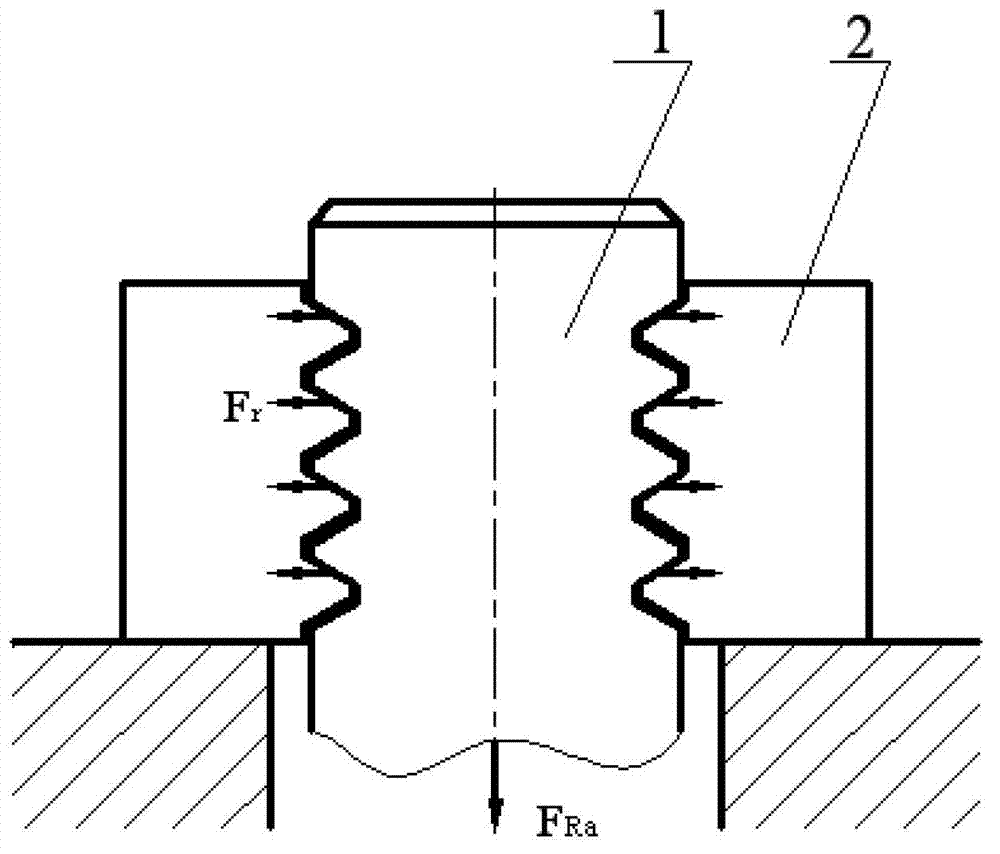

[0028] figure 1 Shown is a specific embodiment of the present invention, which is a front view structural schematic diagram of an iron-based shape memory alloy anti-loosening bolt 1 and a common nut 2 combined into a thread pair; the iron-based shape memory alloy anti-loosening bolt 1 is characterized in that Because: the composition by chemical composition mass percentage is:

[0029] Mn: 16.86%;

[0030] Si: 4.50%;

[0031] Cr: 10.30%;

[0032] Ni: 5.29%;

[0033] C: ≤0.08

[0034] Except for impurities, the remaining components are Fe.

[0035]The manufacturing process of the iron-based shape memory alloy anti-loosening bolt is characterized in that: the smelting material is selected according to the composition requirements of the chemical composition mass percentage, and the smelting material is selected from industrial pure iron (the main impurities are C, Al, etc.), nickel, After mixing electrolytic manganese, silicon, electrolytic chromium and ferrovanadium, each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com