End surface taper centering and interlocking lock nut suite

A technology of taper centering and anti-loosening nuts, which is applied in the direction of nuts, threaded fasteners, locking fasteners, etc., can solve the problems of affecting the service life of the thread, lateral force to the screw, and screw breakage, etc., to achieve Avoid the risk of breakage, eliminate lateral force, convenient and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

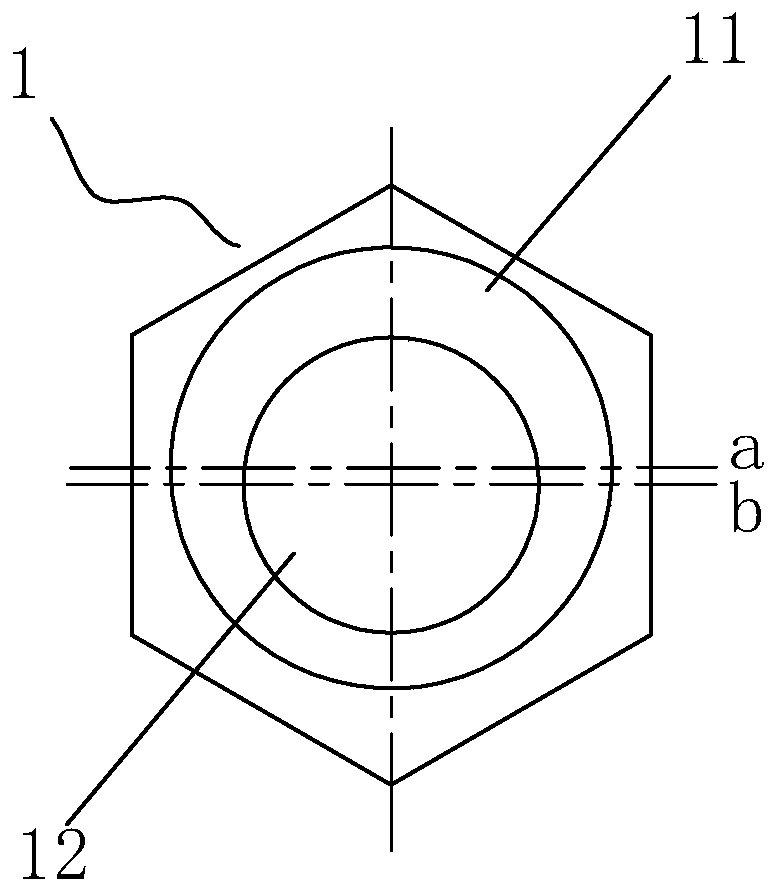

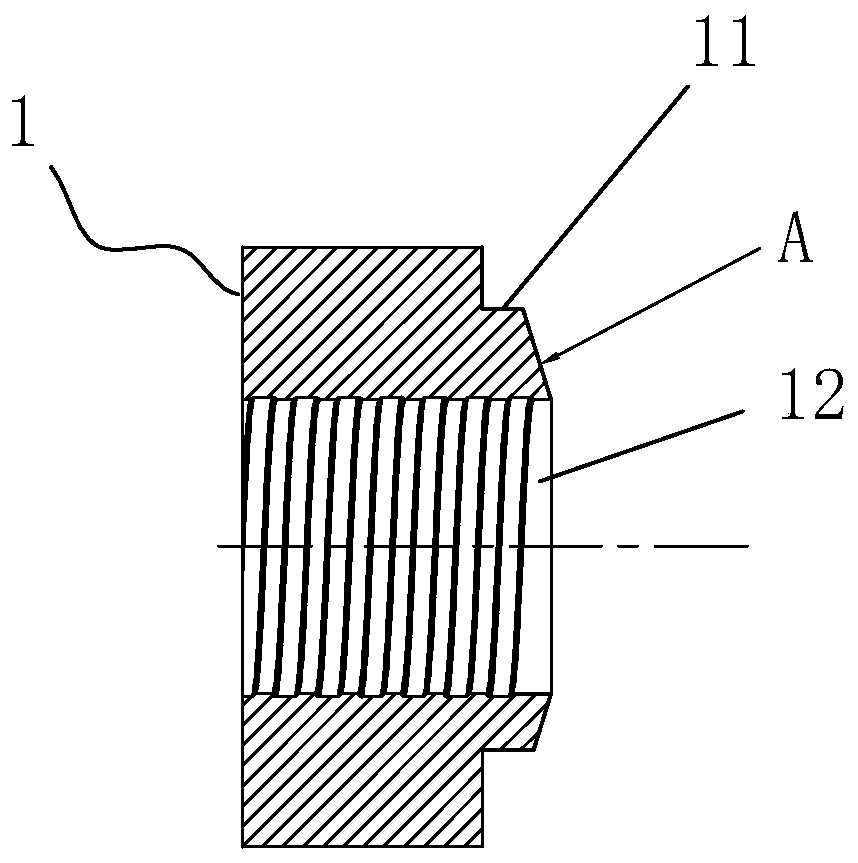

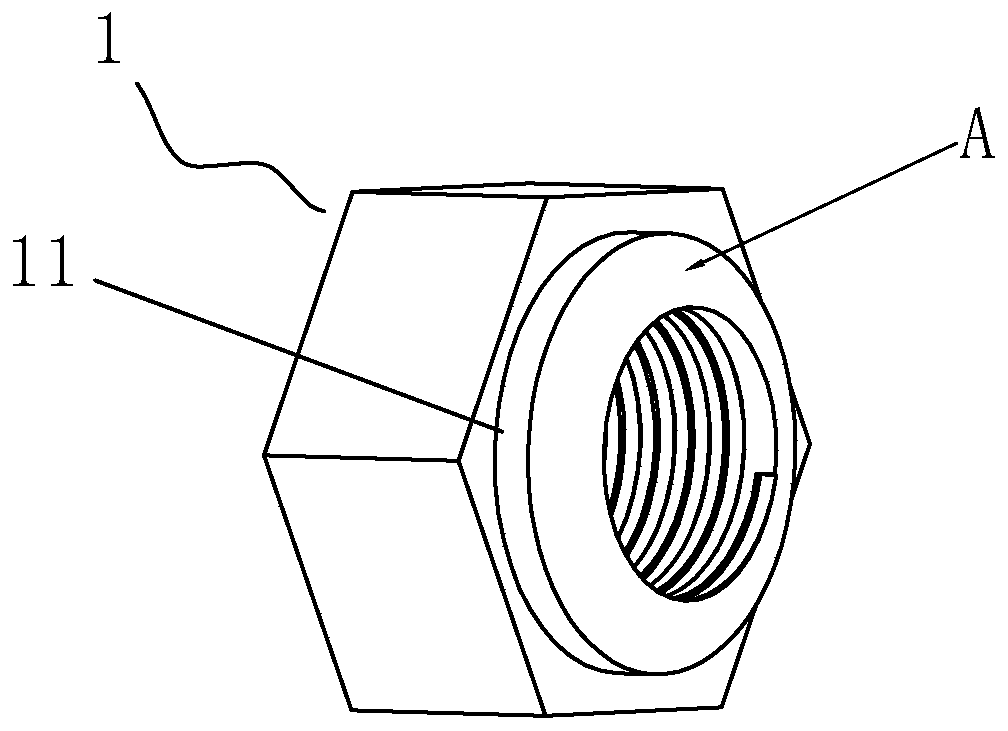

[0041] Such as Figure 1 to Figure 7 As shown, a set of end face taper centering interlock locknuts includes an upper nut I1 with an axial threaded through hole Ia12 and a lower nut I2 with an axial threaded through hole IIa, and the diameter of the threaded through hole Ia12 is the same as The diameters of the threaded through holes IIa22 are the same.

[0042] One end surface of the upper nut I1 is set as a circular boss I11, and the profile of the circular boss I11 is an eccentric circle that is eccentric to the axial threaded through hole Ia12, such as figure 1 As shown, a in the figure represents the center line of the circular boss I11, and b in the figure represents the center line of the axial threaded through hole Ia12; the end face A of the circular boss I11 (see figure 2 , image 3 ) has a taper.

[0043]One end surface of the lower nut I2 is concavely formed with a cylindrical groove I21 compatible with the circular boss I11. The central axis of the cylindrical...

Embodiment 2

[0047] like Figure 9 to Figure 15 As shown, a set of end face taper centering interlock locknuts includes an upper nut II3 with an axial threaded through hole Ib32 and a lower nut II4 with an axial threaded through hole IIb42, and the diameter of the threaded through hole Ib32 is the same as The diameters of the threaded through holes IIb42 are the same.

[0048] One end surface of the upper nut II3 is set as a circular boss II31, the profile of the circular boss II31 is a perfect circle concentric with the axial threaded through hole Ib32, and the upper surface of the circular boss II31 A notch 33 is provided on the end face. like Figure 9 As shown, c in the figure represents the centerline of the circular boss II31, and also represents the centerline of the threaded through hole IIb42, the centerline of the circular boss II31 coincides with the centerline of the threaded through hole IIb42; the circular boss End face C of platform Ⅱ 31 (see Figure 10 , Figure 11 ) h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com