Extrusion assembly nut connection pair and assembly method thereof

An assembly method and a technology of connecting pairs, which are applied in the direction of nuts, connecting members, screws, etc., can solve the problems of high cost, poor anti-loosening performance, and complex structure, and achieve low cost, good anti-loosening performance, and improved anti-loosening performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

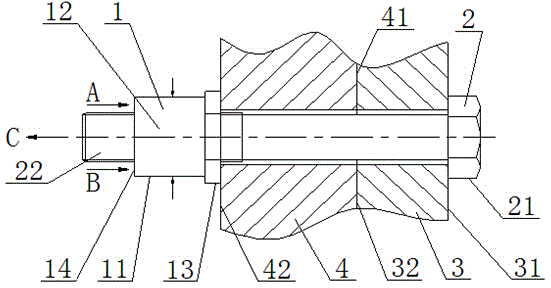

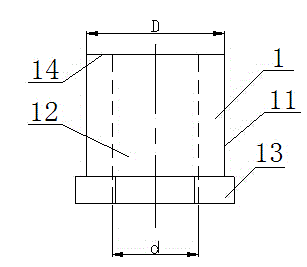

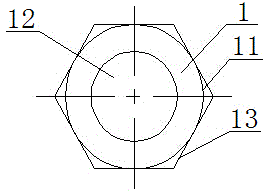

[0047] see Figure 1 to Figure 3 , an extrusion assembly nut connection pair, comprising an extrusion assembly nut 1, an externally threaded fastener 2, the extrusion assembly nut 1 includes a nut body 11; the nut body 11 is a cylinder, and the center of the nut body 11 A through hole 12 is provided, the inner surface of the through hole 12 is a smooth surface, the diameter of the through hole 12 is larger than the major diameter of the external thread of the external thread fastener 2, and one end of the nut body 11 is provided with a nut flange surface 13, the nut flange The structure of the surface 13 is quadrangular, hexagonal, dodecagonal, hexagonal or flat.

[0048] According to the above scheme, an assembly method for extruding and assembling a nut connection pair, the assembly method includes the following steps in sequence: first, the external thread fastener 2 is inserted into the inner hole of the first connecting piece 3 in turn, and the second connecting piece 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com