Engagement and disengagement module of intelligent lock

A smart lock and clutch technology, which is applied in the field of smart locks, can solve the problems that the clutch pin cannot be inserted into the clutch block, the installation and parts have high precision requirements, and the handle screws come back loose, so as to increase the anti-loosening effect and ensure smooth insertion. The effect of reducing air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

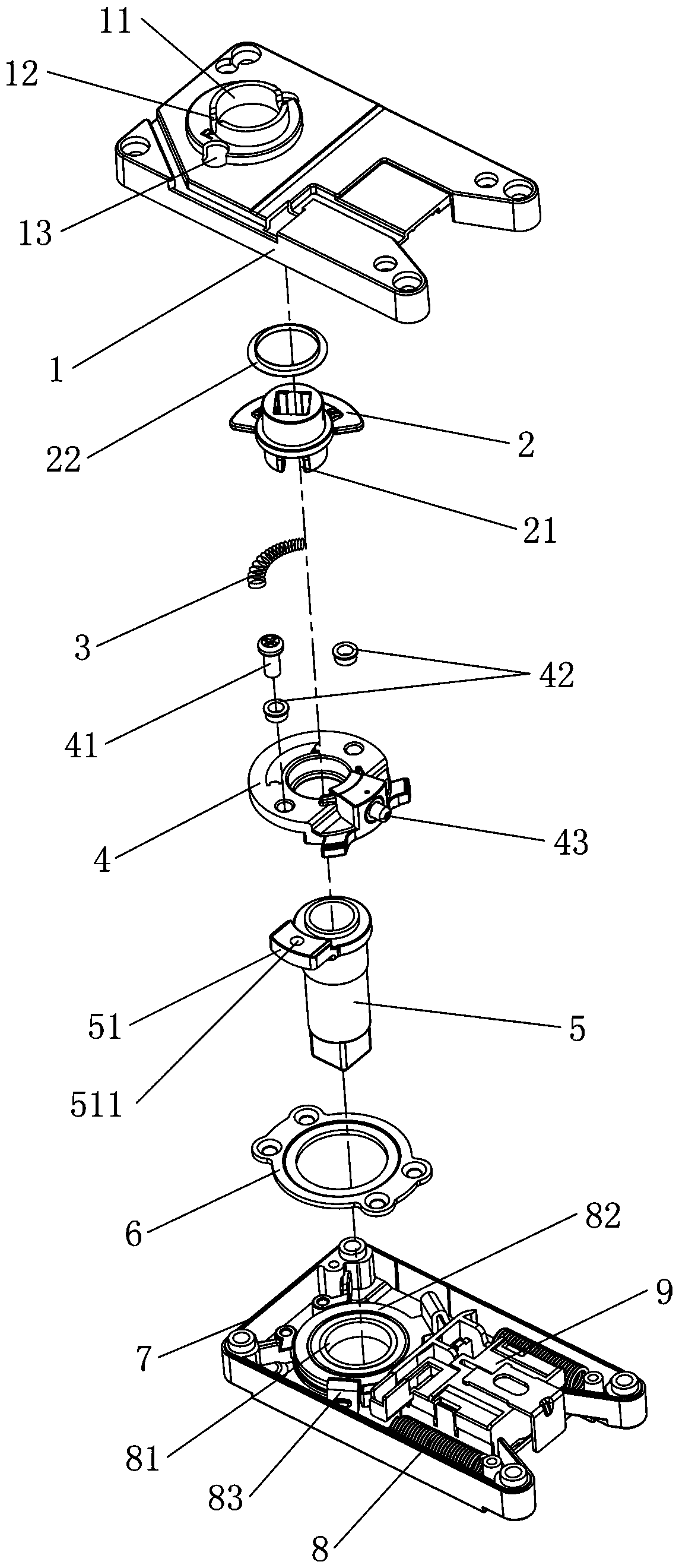

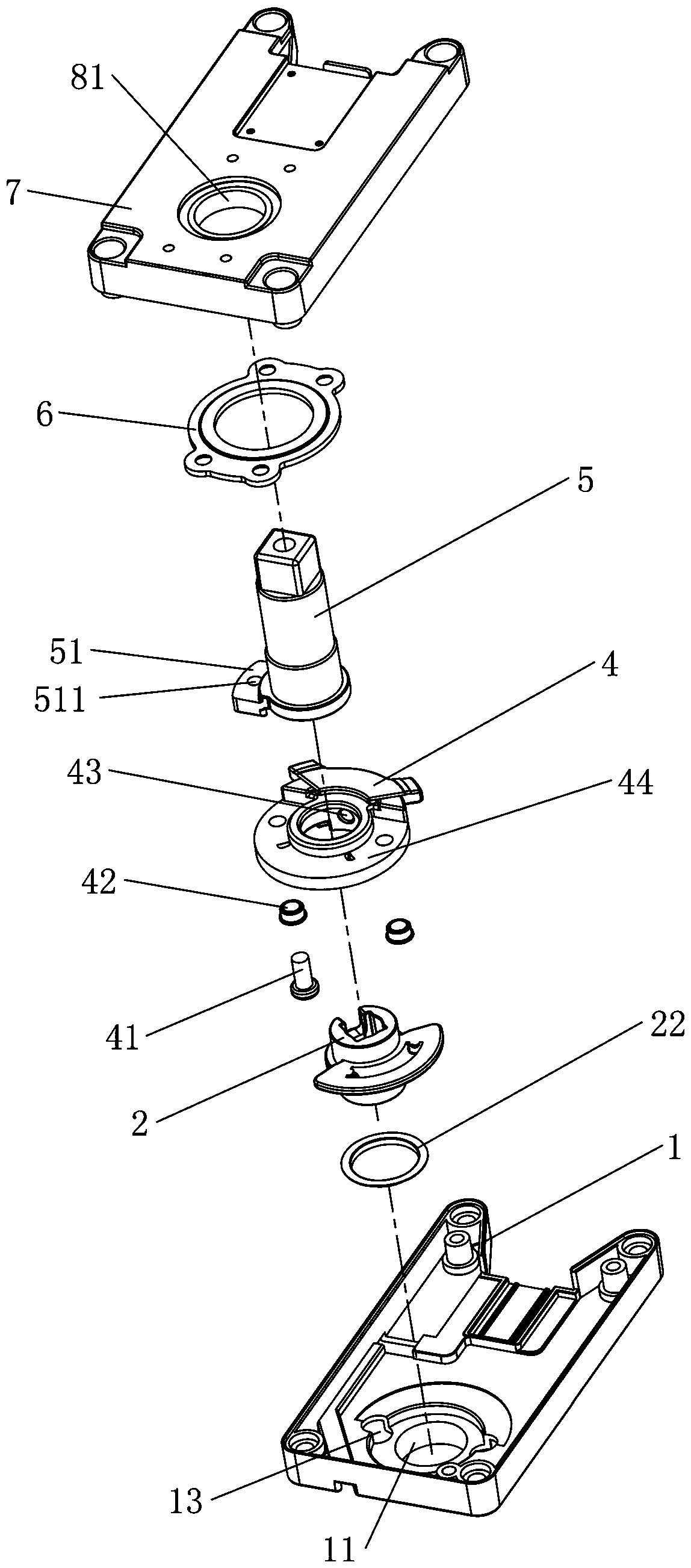

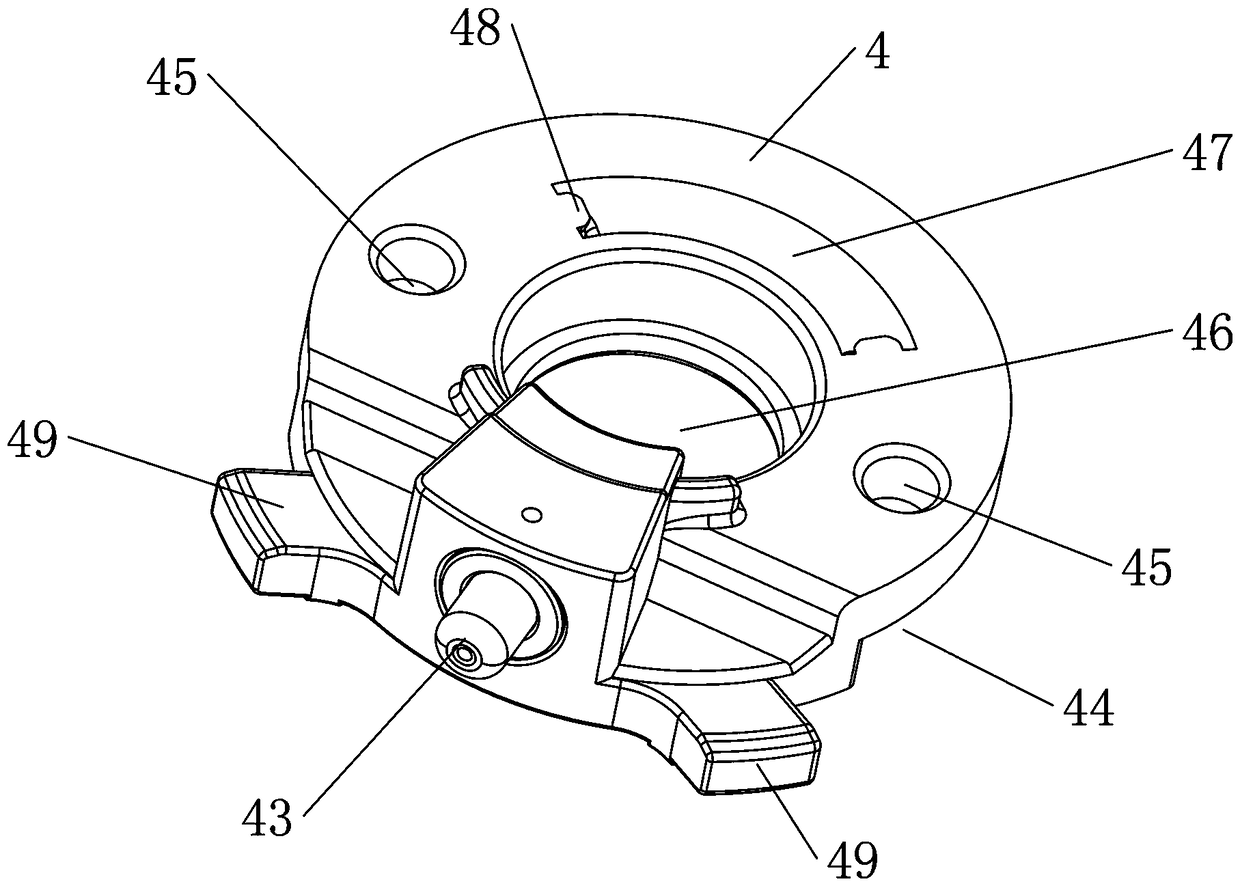

[0028] see Figure 1 to Figure 7 As shown, a smart lock clutch module includes a housing, a handle 5, a clutch block 2, a clutch sleeve 4, a clutch pin 43 and an electric push rod 91 for driving the clutch pin 43, and the clutch sleeve 4 is rotatably arranged on the shell In the body, the clutch sleeve 4 is provided with a central hole 46, and the clutch pin 43 is radially arranged on the clutch sleeve 4, and extends out of the central hole 46 and the outer periphery of the clutch sleeve 4 from both ends; 46, and corresponding to the clutch pin 43, a clutch bayonet 21 is provided. One end of the clutch block 2 protrudes outside the clutch sleeve 4, and a baffle plate 24 is arranged on its outer periphery. The surface of the clutch sleeve 4 corresponds to the left and right sides of the center hole 46. Holes are respectively provided, and a reversing sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com