Nut assembly with reliable locking performance

A technology for locking nuts and components, applied in the direction of locking fasteners, nuts, threaded fasteners, etc., can solve problems such as loosening, and achieve the effects of convenient production and installation, excellent anti-loosening performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the present invention will be described in detail below in conjunction with specific drawings.

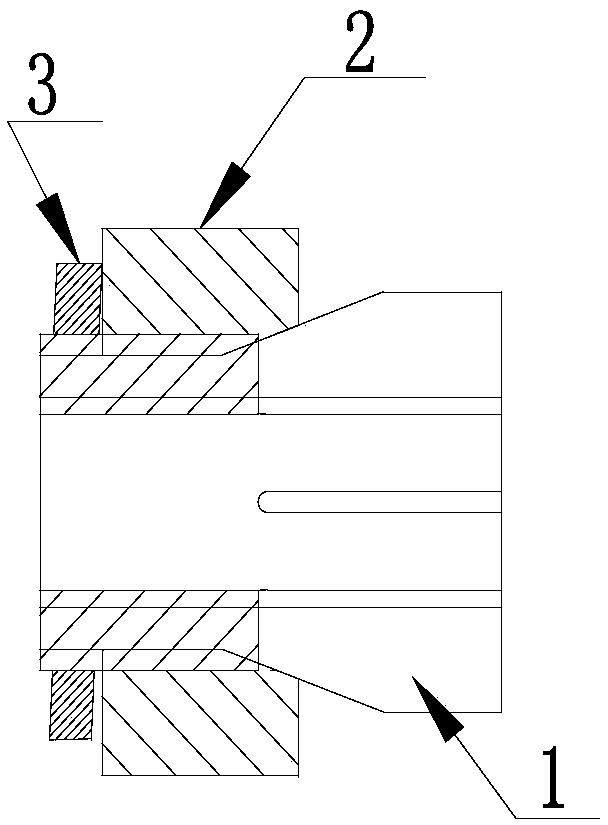

[0024] The nut assembly provided by the invention, such as figure 1 As shown, it includes a lock nut 1, a drive nut 2 and an elastic washer 3.

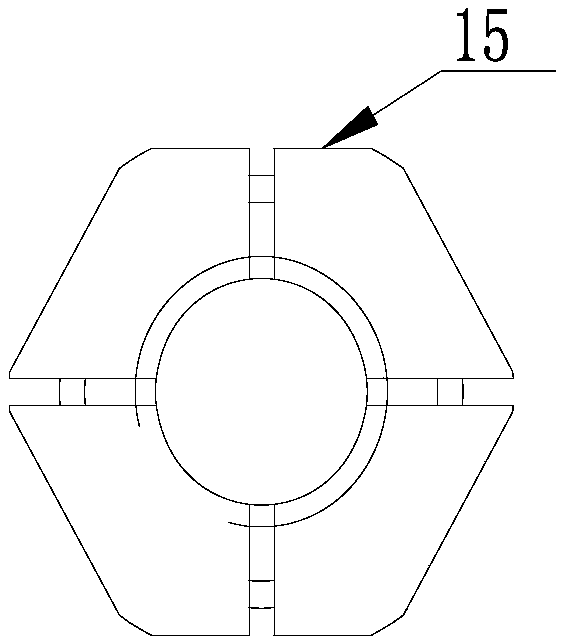

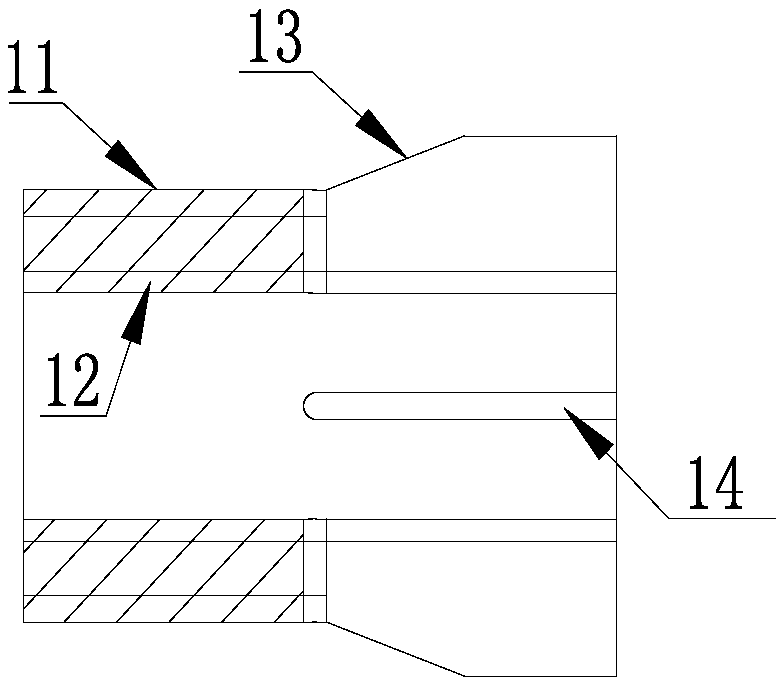

[0025] The lock nut 1 ( Figure 2-3 ) includes coaxial external threads 11 and internal threads 12 with different rotation directions. The external threads 11 and internal threads 12 are full threads at the equal diameter part of the locknut 1 where they are located, but are not limited to full threads, as long as they meet Lock the required thread length. The lock nut 1 is provided with an external diameter reducing part 13, the outer diameter of the reducing diameter part 13 increases from the side where the external thread 11 is located to the other side, and the shape of the reducing diameter part 13 can be tapered or other forms , such as an umbrella. The tail of the lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com