Slack preventive fastener for screw tool, and method and device for manufacturing the same

A manufacturing method and technology for connecting parts, applied in the direction of threaded fasteners, screws, nuts, etc., can solve problems such as complicated use methods, difficult threaded parts or connecting parts, and unusability, so as to avoid excessive tightening torque The final fastening, preventing loosening or falling off, easy and reliable anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] (The structure of the anti-loosening joint of the threaded part)

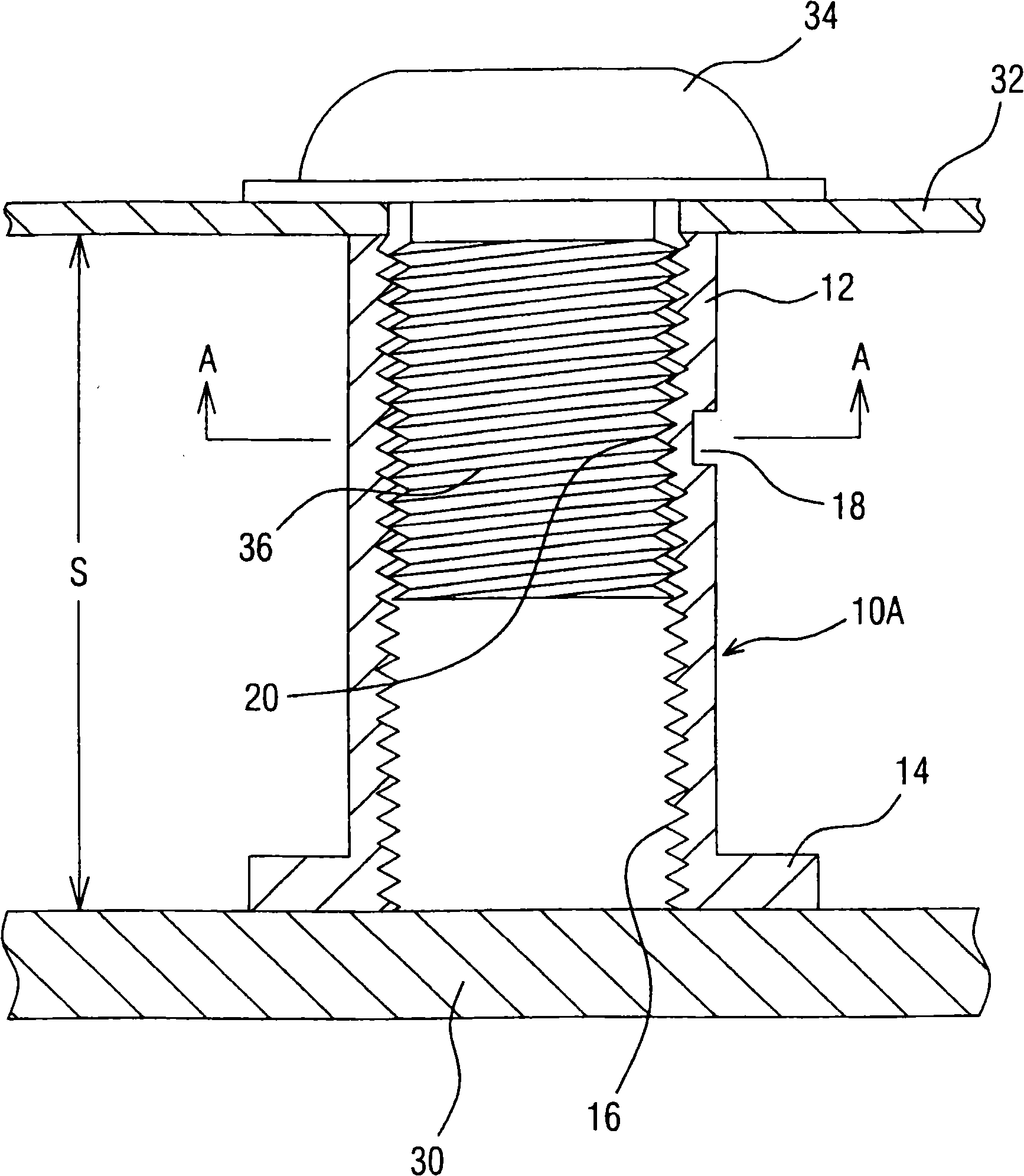

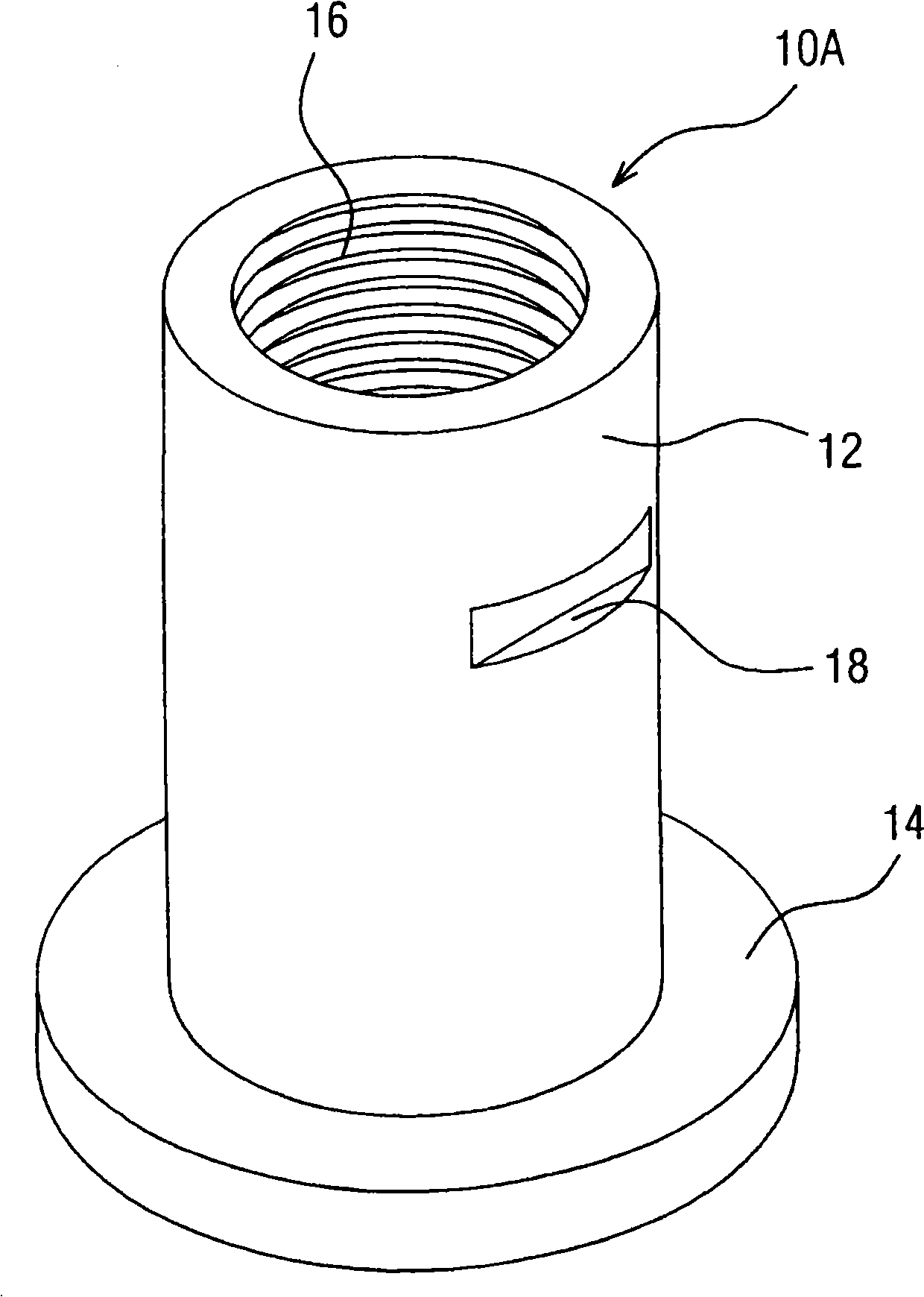

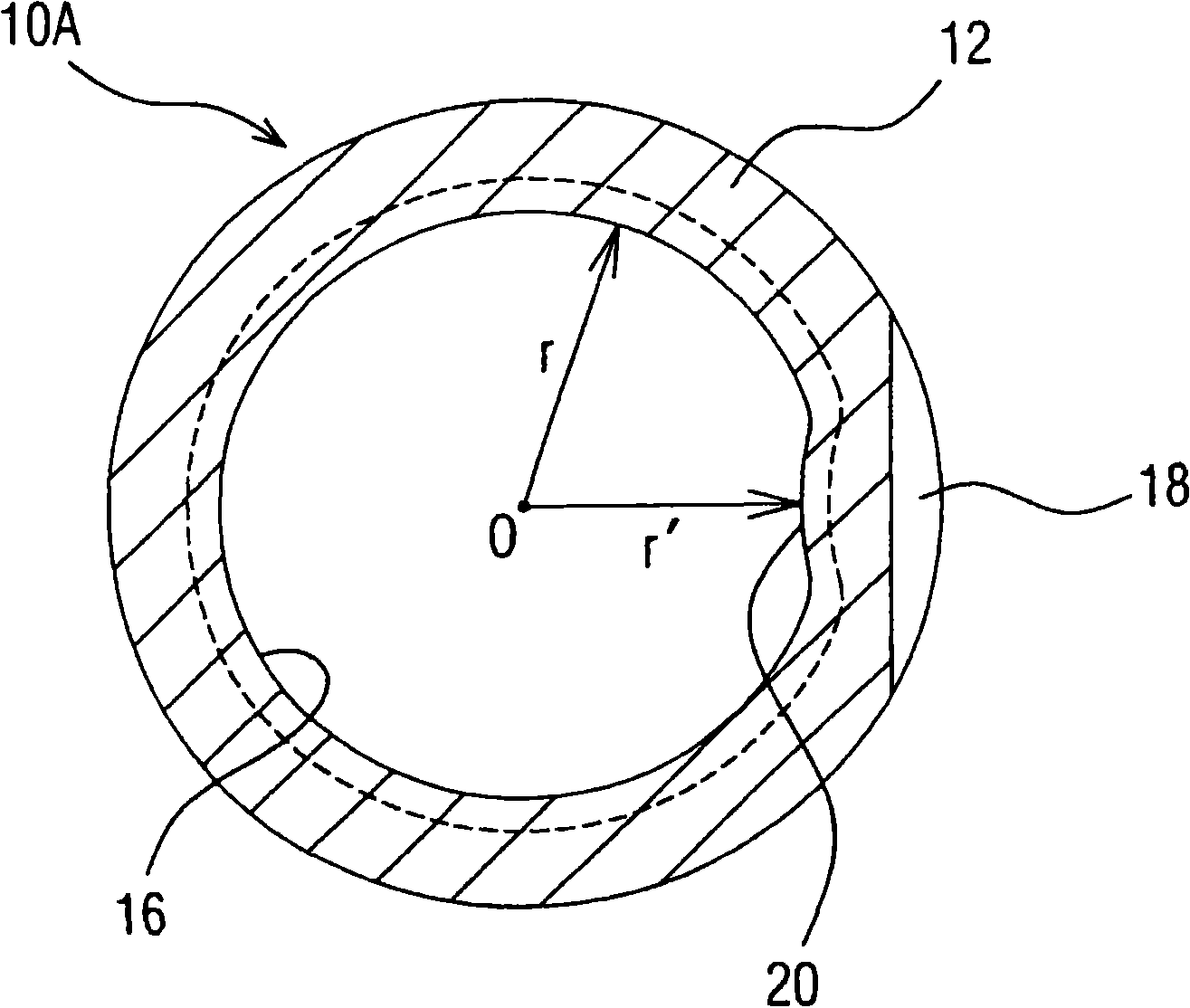

[0095] Figure 1 to Figure 3 An example of the anti-loosening fastening member of the screw according to the present invention is shown. figure 1 It is a longitudinal sectional view of the main part of the anti-loosening joint of the present embodiment showing the state of being connected with the screw, figure 2 is a perspective view of the connector of this embodiment, image 3 yes figure 1 A cross-sectional view of the main part of the connecting member shown along line A-A.

[0096] exist figure 1 Among them, reference numeral 10A represents a connecting member of the present invention, and this connecting member 10A is configured so that when a mounting substrate 32 as a cover plate is fixed via a required space S to an object 30 to be mounted as an integrated circuit substrate , and a coupling member 10A serving as a bush for holding the above-mentioned space S is provided. Therefore, the co...

Embodiment 2

[0105] (The structure of the anti-loosening joint of the threaded part)

[0106] Figure 7 to Figure 9 It is another embodiment of the anti-loosening joint of the threaded part of the present invention. Figure 7 It is a longitudinal sectional view of the main part of the anti-loosening connector of the present embodiment, Figure 8 is a perspective view of the connector of this embodiment, Figure 9 yes Figure 7 B-B line sectional view of the main part of the connecting member shown. In addition, for convenience of explanation, the same reference numerals will be used for the same constituent elements as those of the coupling tool of the first embodiment described above.

[0107] exist Figure 7 Herein, reference numeral 10B denotes a coupling member of this embodiment, and this coupling member 10B is a coupling member 10B as a bushing similar to that of the first embodiment, and in particular, the cylindrical main body 12 is formed to have a thick wall. Therefore, if ...

Embodiment 3

[0114] (The structure of the anti-loosening joint of the threaded part)

[0115] Figure 11 to Figure 13 It is another embodiment of the anti-loosening joint of the threaded part of the present invention. Fig. 11 is a longitudinal sectional view of main parts of the anti-loosening connector of the present embodiment, Figure 12 is a perspective view of the connector of this embodiment, Figure 13 It is a cross-sectional view of main parts along line C-C of the coupling shown in FIG. 11 . In addition, for convenience of explanation, the same reference numerals will be used for the same constituent elements as those of the coupling tool of the first embodiment described above.

[0116] in Figure 11 and Figure 12 In the figure, reference numeral 10C represents the coupling tool of this embodiment, and this coupling tool 10C is a coupling tool 10C configured as a hexagonal nut. On the inner peripheral surface of the hex nut main body 13 of the coupling 10C made of the hex nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com