Locking positioning structure

A locking positioning and nut technology, applied in the direction of locking fasteners, connecting members, threaded fasteners, etc., can solve problems such as jamming, limitations of applicability and practicability, and difficult-to-lock structures, and achieve structural settings. Reasonable, improve the fixed effect, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

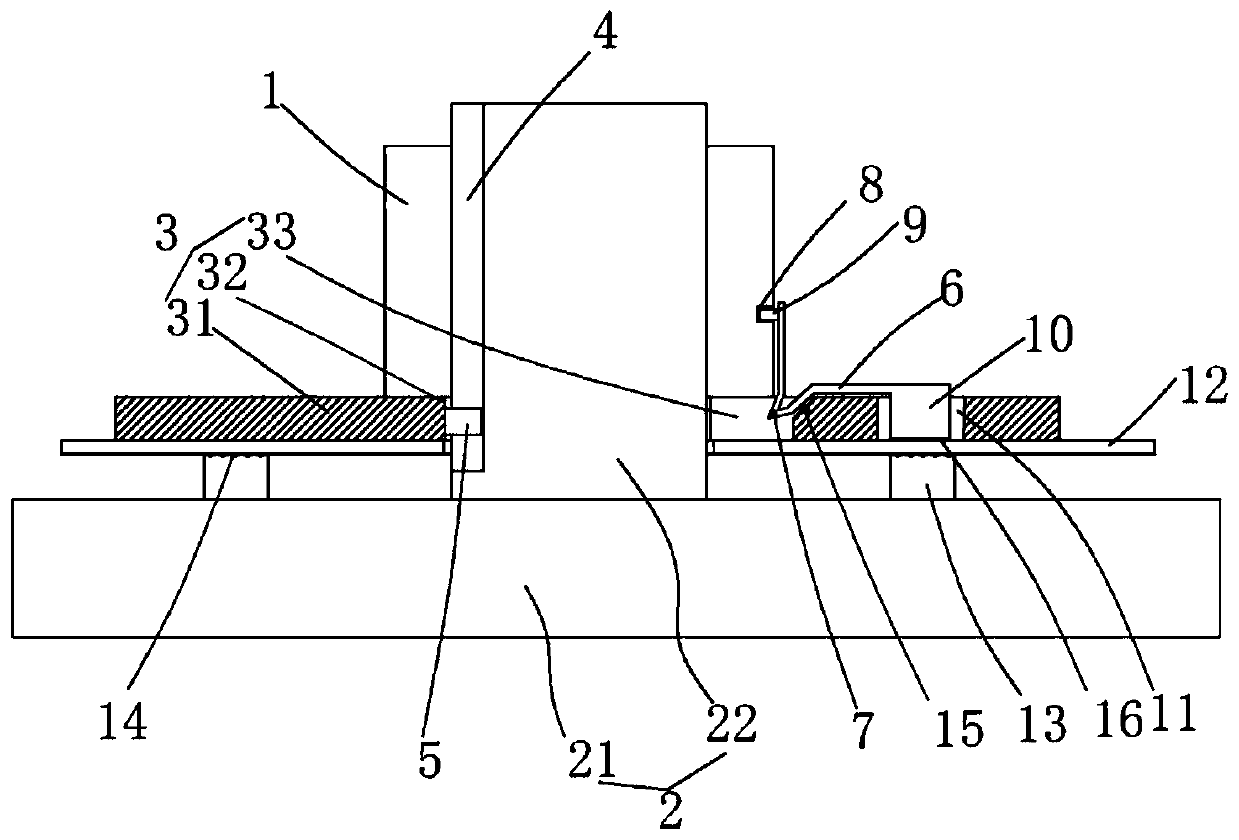

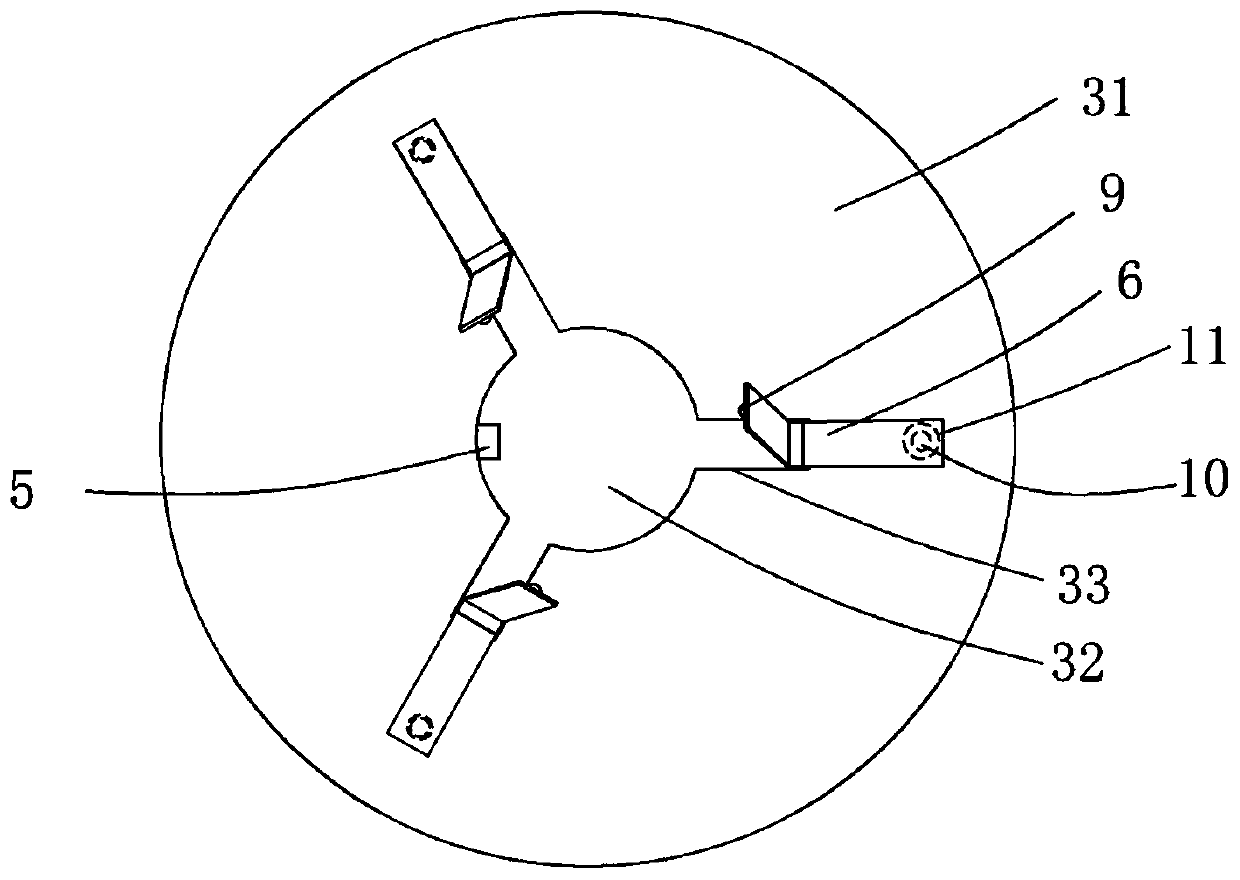

[0018] figure 1 and figure 2 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a specific structural schematic diagram of the locking structure of the present invention.

[0019] See figure 1 and figure 2 , a locking and positioning structure, including a bolt 2 and a nut 1, the bolt 2 includes a stud 21 and a nut 22, and a locking structure 3 is also provided between the nut 1 and the nut 22, so The locking structure 3 includes a backing plate 31, a circular hole 32 with the same diameter as the stud is opened in the center of the backing plate, and at least three grooves 33 are uniformly opened on the inner ring of the backing plate, The depth of the groove is the same as the thickness of the nut, and a vertical clamping groove 4 is provided on the side wall of the stud, and the vertical clamping groove 4 is integrally formed on the inner ring of the backing plate. The posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com