A mechanism real gold color steel plate production line

A color steel plate and production line technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problem of troublesome disassembly and assembly of core barrels, improve production efficiency and convenience, facilitate axial movement, and facilitate disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

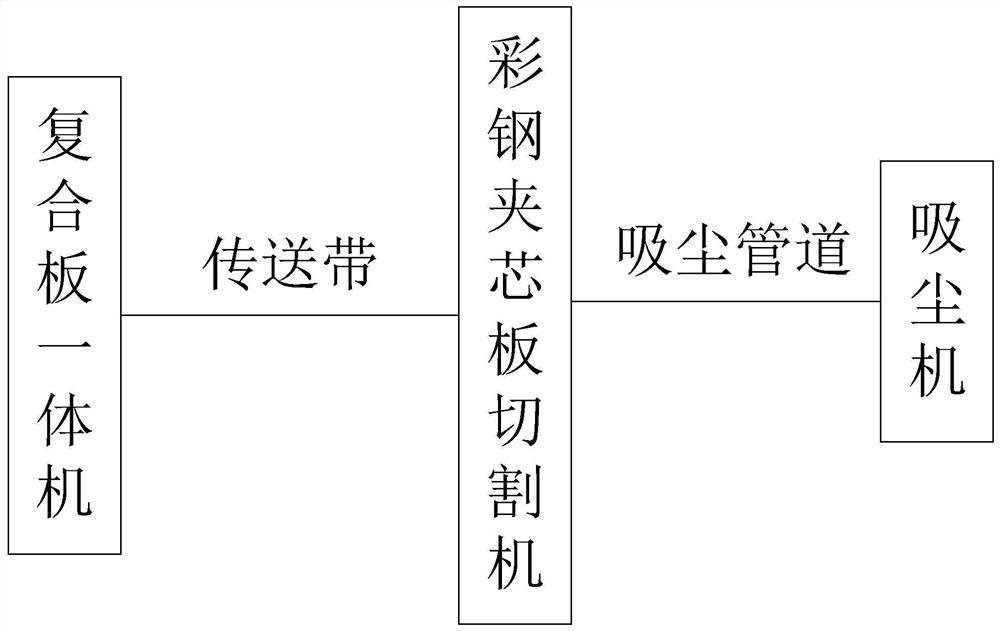

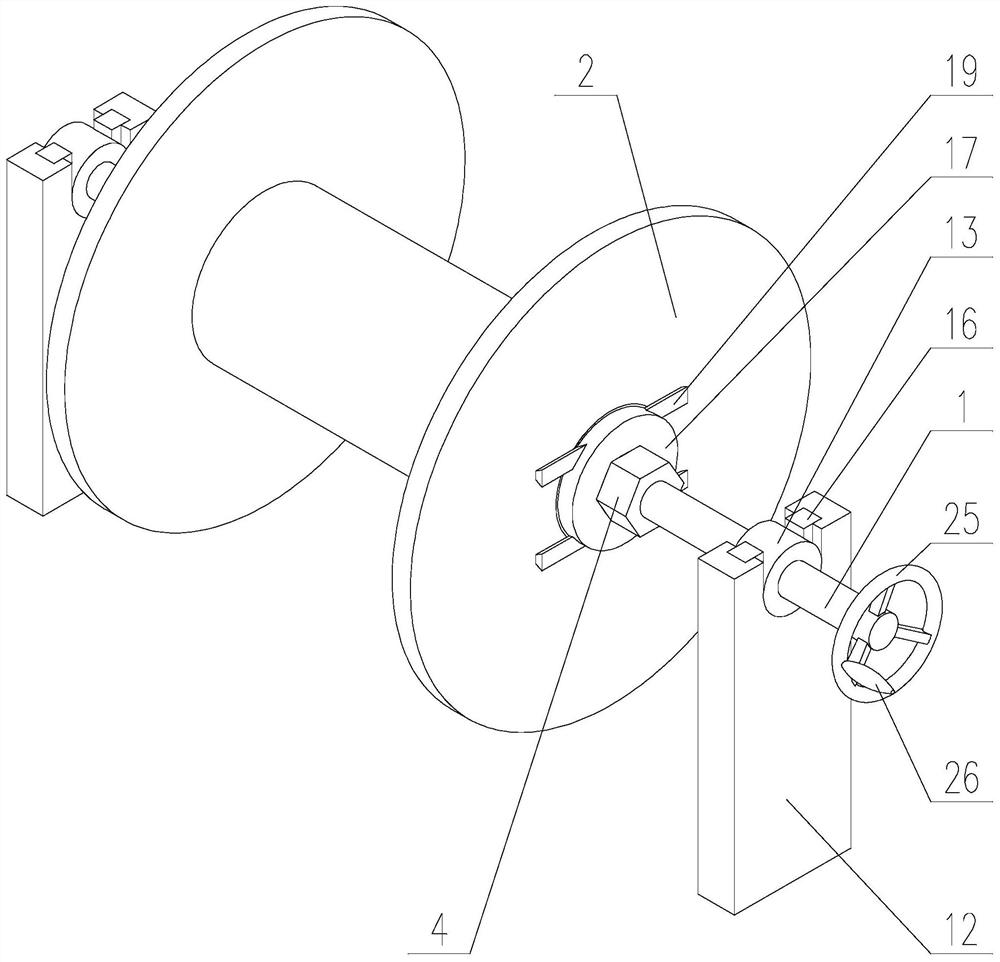

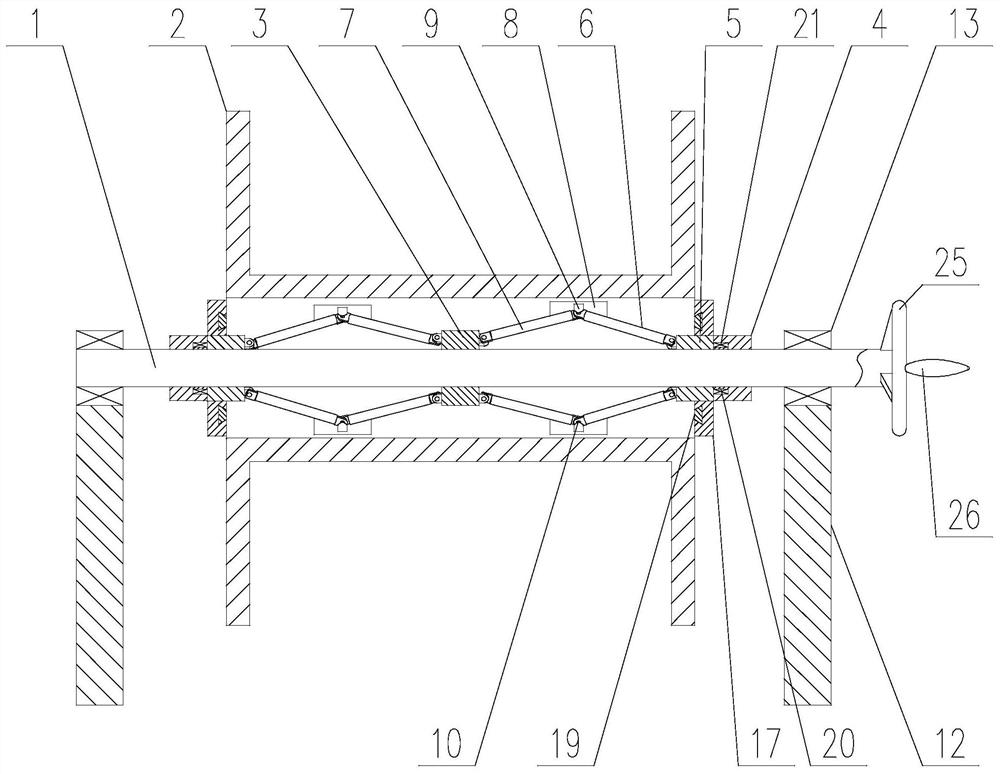

[0044] like Figure 1-Figure 11 As shown, a machine-made real gold color steel plate production line of the present invention includes a composite plate integrated machine and a machine-made real gold color steel plate cutting machine, and the discharge end of the composite plate integrated machine is connected to the feed end of the machine-made real gold color steel plate cutting machine , a steel coil feeding device is provided on the composite board integrated machine, and the steel coil feeding device includes a rotating shaft 1, two supporting assemblies respectively supporting the two ends of the rotating shaft 1, sleeved on the rotating shaft 1 and located at two The core barrel 2 between the shaft support assemblies is provided with threads on the side wall of the rotating shaft 1, and an intermediate ring 3 is sleeved on the middle part of the rotating shaft 1, and tops are provided on both sides of the intermediate ring 3. Tightening assembly, the tightening assembl...

Embodiment 2

[0059] This embodiment is a further description of the axial fixation of the core barrel.

[0060] like Figure 2-Figure 8 As shown, in the present invention, a pressure ring 17 is sleeved on the moving ring 5, and the outer diameter of the pressure ring 17 is smaller than the diameter of the central hole of the core barrel 2, and the pressure ring 17 is close to the middle ring 3. One side is all provided with chute 18, and the opening size of described chute 18 is smaller than the groove bottom size, and its extension direction is parallel to the horizontal plane, and in chute 18, all is slidably provided with retaining bar 19, and the cross-section of described retaining bar 19 The shape and size of the chute 18 are consistent with the shape and size of the cross section of the chute 18, and the length of the bar 19 is greater than the diameter of the central hole of the core tube 2.

[0061] Although the core cylinder 2 can maintain its synchronization with the rotating s...

Embodiment 3

[0073] This embodiment is a specific implementation description for the outer surface of the contact shaft 8 .

[0074] In the present invention, a non-slip rubber layer is provided on the side wall of the contact shaft 8 . The arrangement of the anti-slip rubber layer further increases the frictional force between the contact shaft 8 and the core cylinder, which is beneficial to further improve the synchronization between the core cylinder and the contact shaft 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com