High pressure common rail fuel delivery pump with adjustable pressure and flow rate

A high-pressure common rail, adjustable technology, used in fuel injection pumps, engine components, machines/engines, etc., can solve the problems of inability to adjust the pressure and flow of the fuel pump, poor controllability, inconvenience, etc., to avoid high frequency The effect of impact, prolonging life and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

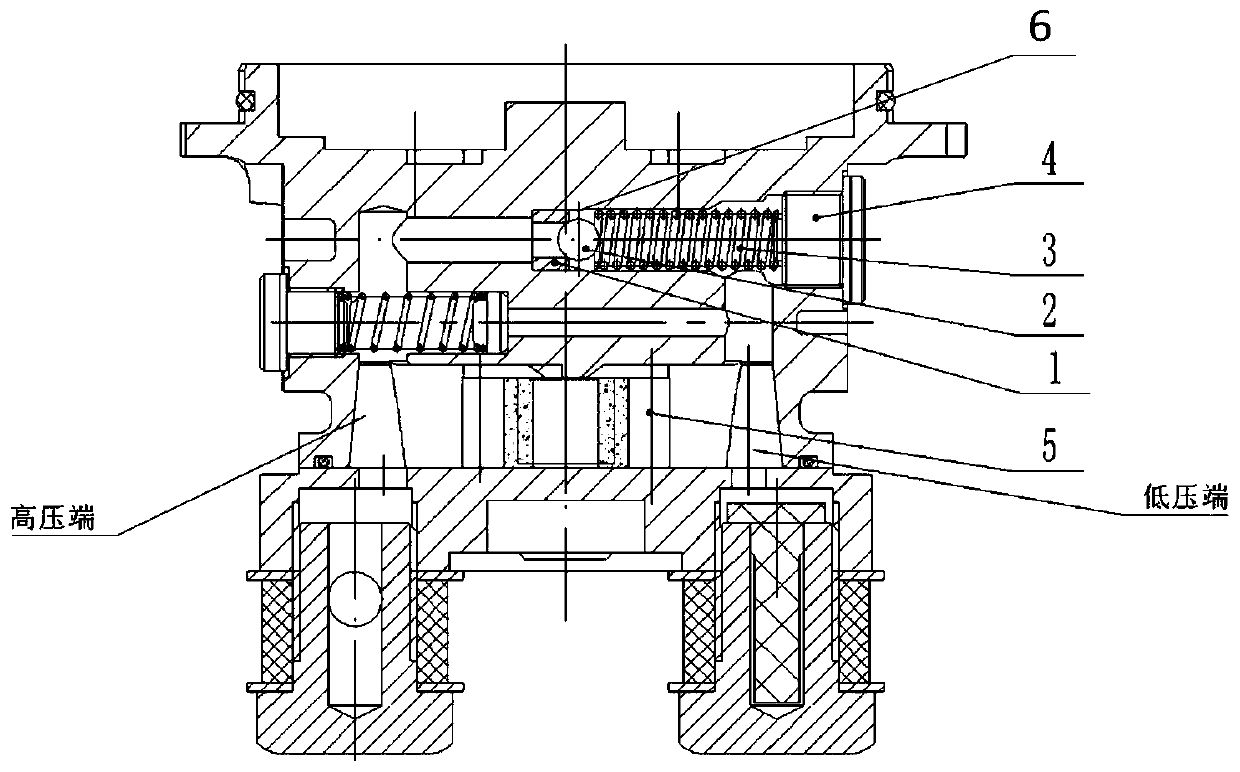

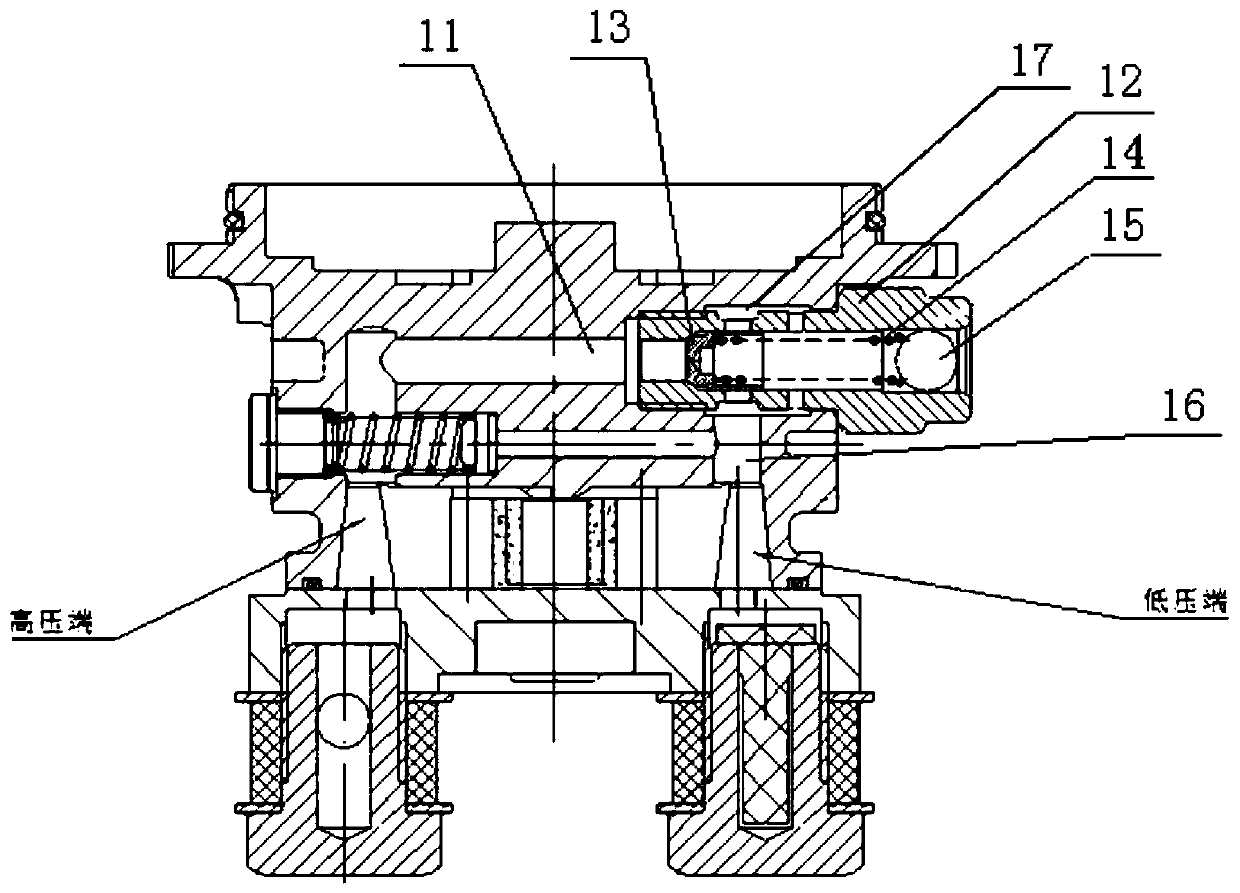

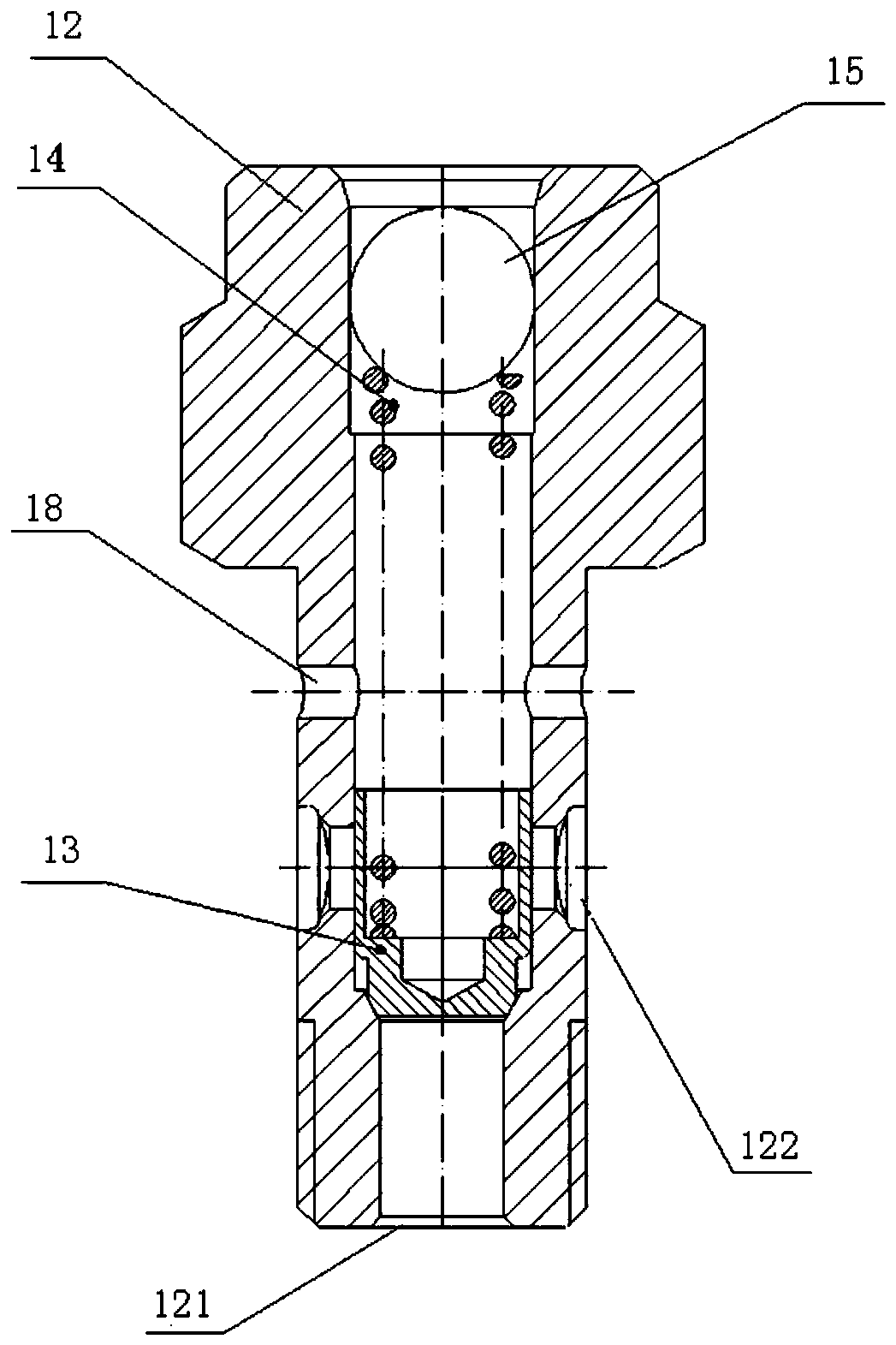

[0024] Refer to attached figure 2 with 3 As shown, the high-pressure common rail fuel delivery pump in this embodiment that can adjust the pressure and flow includes an adjusting slide valve arranged on the fuel passage 11 at the high-pressure end of the pump body. The adjusting slide valve includes a slide valve body 12 and a slide valve core 13. , Overflow spring 14 and fixed plug 15.

[0025] The slide valve body 12 is fixed on the high-pressure end fuel passage 11, and the slide valve body 12 is a hollow pipe, wherein an open end 121 of the hollow pipe communicates with the high-pressure end fuel passage 11, and the pipe wall of the hollow pipe An oil drain hole 122 is arranged on the top, and the oil drain hole 122 communicates with the fuel input channel 16 at the low pressure end of the pump body. The spool 13, overflow spring 14 and fixed plug 15 are sequentially arranged inside the hollow tube. The spool 13 is a cylindrical piston. , move axially along the hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com