Uncoiling and discharging machine for coiled plates

A technology of feeding machine and coiling plate, applied in the field of coiling plate unwinding equipment, can solve the problems of inconvenient use, difficult to adapt to different specifications of coiled plate materials, unable to adapt to various specifications of coiled plate materials, etc., to achieve simple structure, Use flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

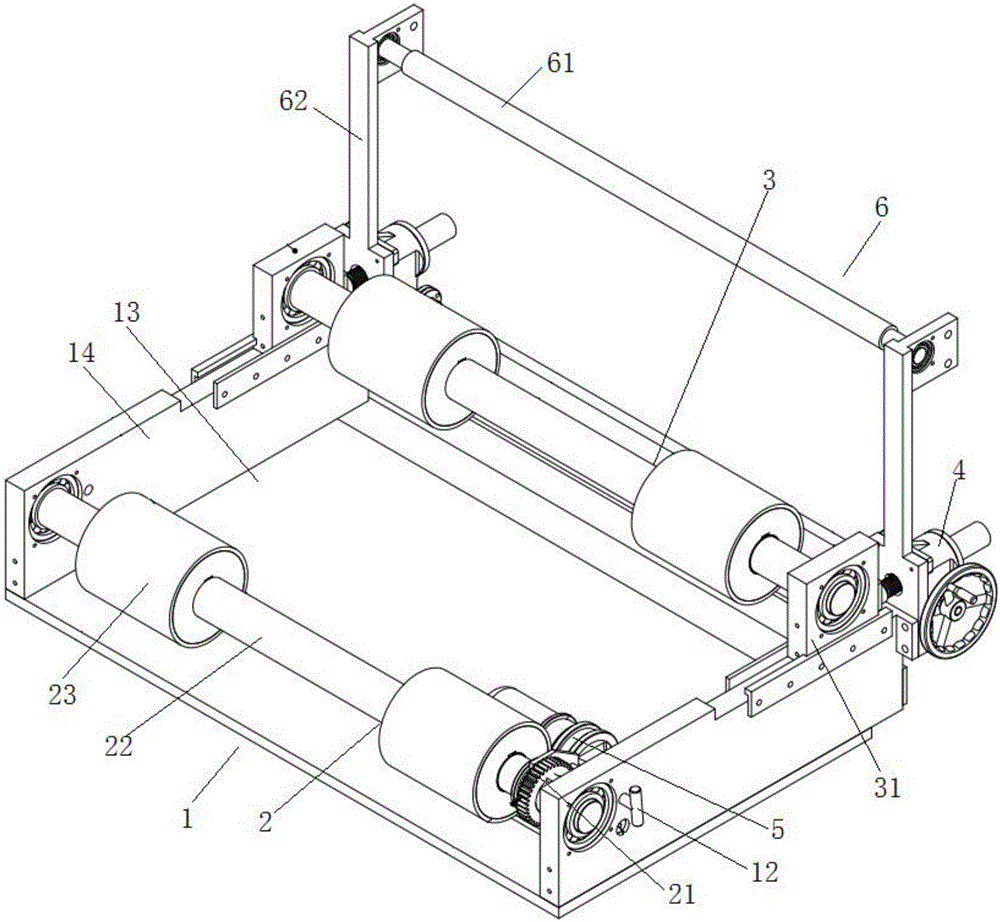

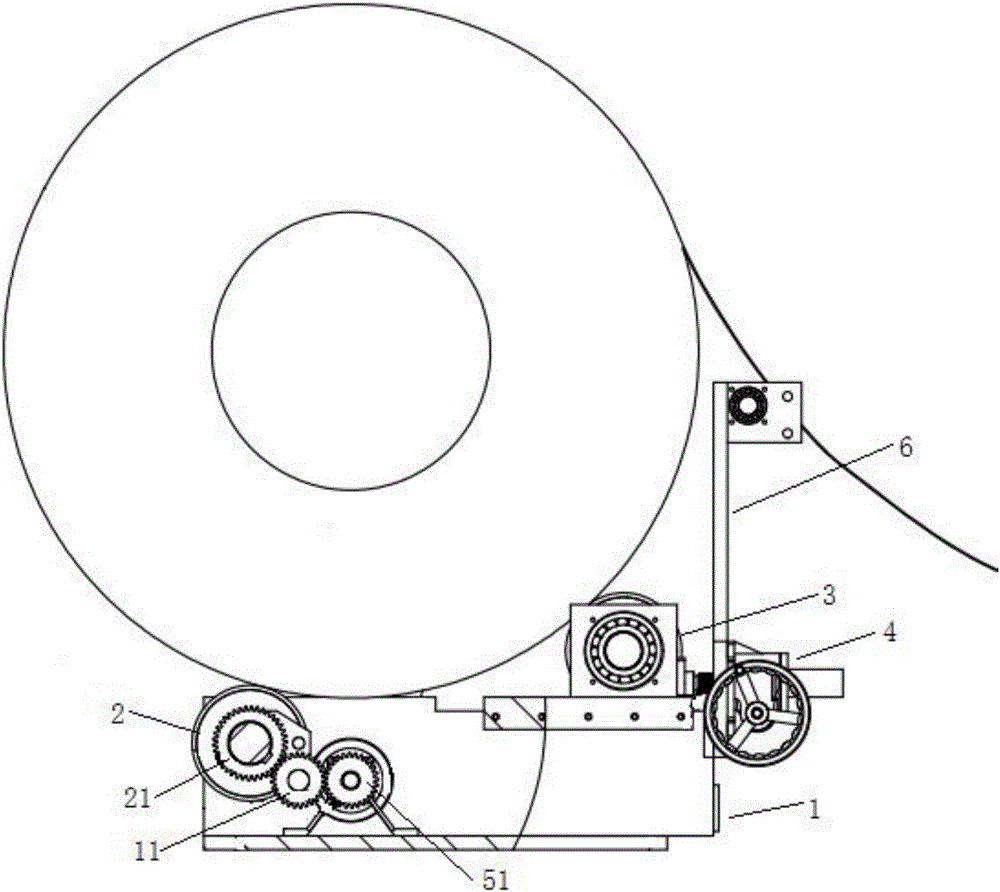

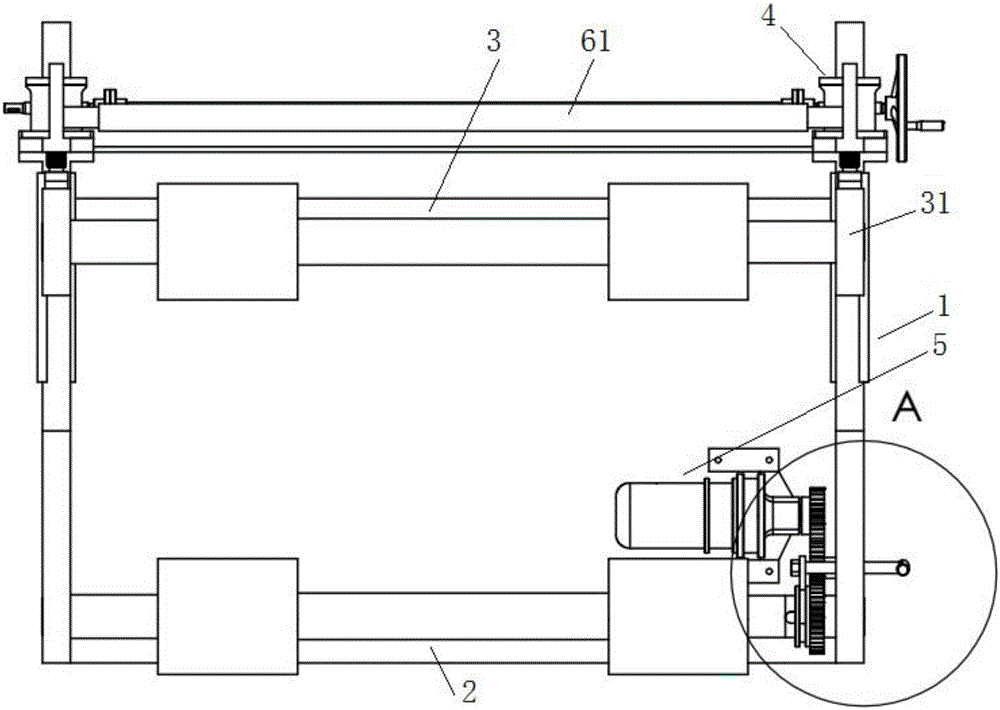

[0037] Example: such as Figures 1 to 5 As shown, the coil unwinding and unwinding machine of this embodiment includes a mounting bracket 1, a first roller shaft assembly 2, a second roller shaft assembly 3, a power pushing device 4 and a rotation driving device 5;

[0038] The above-mentioned first roller shaft assembly 2 and the second roller shaft assembly 3 are arranged horizontally and spaced in parallel, the above-mentioned first roller shaft assembly 2 is rotatably mounted on the above-mentioned mounting bracket 1; the two ends of the above-mentioned second roller shaft assembly 3 pass through the bearing seat 31 is slidably installed on the above-mentioned mounting bracket 1;

[0039] The above-mentioned power pushing device 4 is installed on the above-mentioned installation bracket 1, and can push the second roller shaft assembly 3 to move horizontally along the installation bracket 1 to approach or move away from the first roller shaft assembly 2 through the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com