Threshing device

A technology of threshing device and wallboard, which is applied in the direction of threshing equipment, application, agricultural machinery and implements, etc. It can solve the problems of blockage, excessive feeding of threshing device, etc., and achieve the effect of reducing grain loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

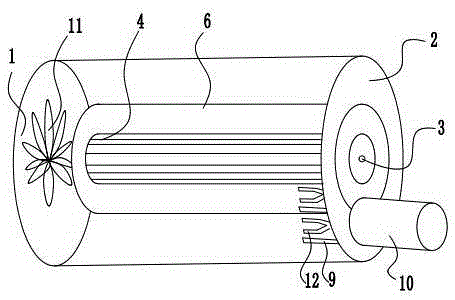

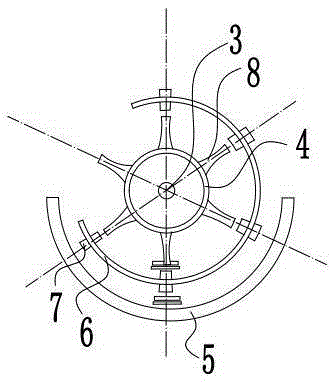

[0023] The reference signs in the accompanying drawings of the specification include: left wallboard 1, right wallboard 2, roller shaft 3, spiked roller 4, concave plate sieve 5, shell 6, protrusion 7, spiked teeth 8, collecting tank 9, miscellaneous Material pipe 10, fan 11, jaw 12.

[0024] as attached figure 1 And attached figure 2 Shown: a threshing device, including a left wall panel 1, a right wall panel 2 fixed on the harvester or the fuselage of the harvester, and a cleaning device arranged on the left wall panel 1 and the right wall panel 2, the left wall panel 1 and the right wall panel 2 is provided with a roller shaft 3, the outer surface of the roller shaft 3 is provided with a nail-toothed roller 4, a concave plate sieve 5 is arranged under the nail-toothed roller 4, and a sieve hole is arranged on the concave plate sieve 5; 5 is connected between the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com