Synthetic adhesive cutting machine

A shredder and synthetic rubber technology, which is applied in grain processing and other directions, can solve the problems of different sizes of cut pieces, high production cost and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

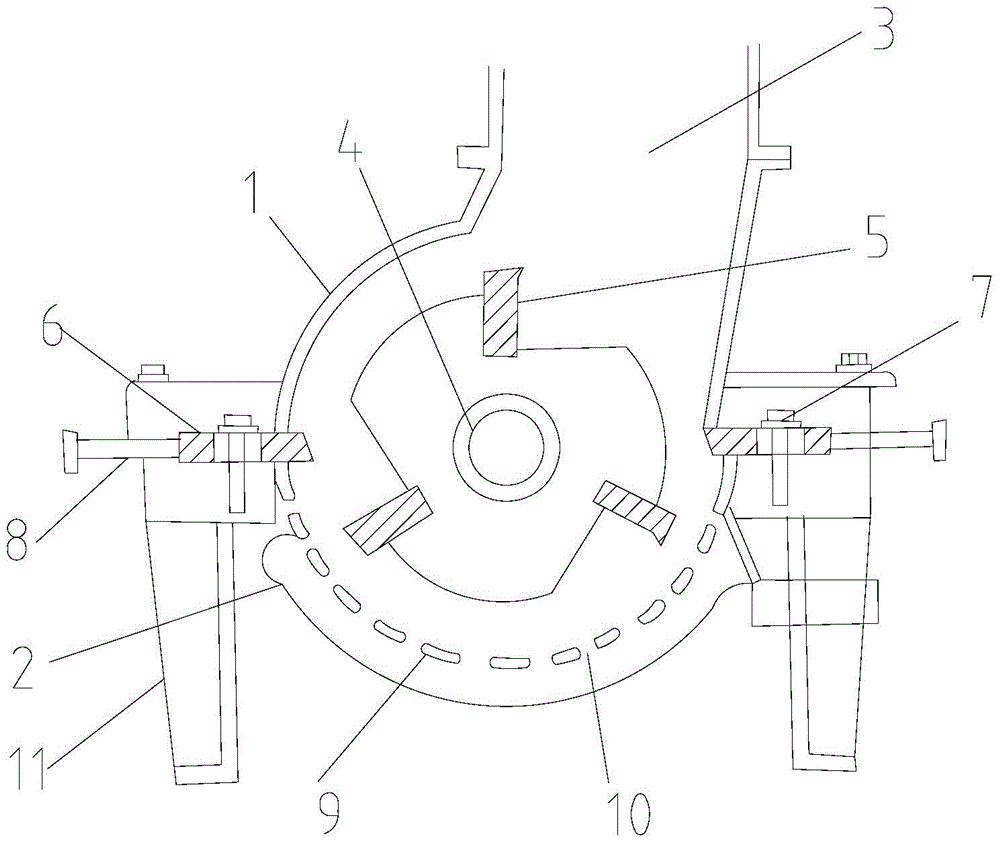

[0011] As shown in the figure, the synthetic rubber shredder includes an upper casing 1 and a lower casing 2, the upper casing 1 is arranged above the lower casing 2, the upper end of the upper casing 1 is connected with a hopper 3, the upper casing 1 and the lower casing A circular cavity is formed between the casings 2, and a rotor 4 is arranged in the cavity, and a blade 5 is arranged on the rotor 4, and the blade 5 rotates and cuts the large piece of rubber into small pieces, and the upper casing 1 and the lower casing 2 A number of fixed cutting knives 6 are arranged between them, and the fixed cutting knives 6 cooperate with the blades 5 on the rotor 4 to facilitate the cutting of large rubber blocks. The upper part of the fixed cutting knives 6 is provided with mounting holes, and the fixed cutting knives connect with the lower ones through the positioning pins 7. The housing is connected, and the diameter of the positioning pin is smaller than the diameter of the mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com