Cutting platform for glass fiber reinforced plastic products

A cutting platform, fiberglass technology, applied in the direction of metal processing, etc., can solve the problems of inability to cut fiberglass profiles, endanger the heart and lung function of workers, maintain the processing environment, etc., to achieve convenient axial movement, ingenious design, fast compression and smooth transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the techniques, creative characteristics of the present invention, it is easy to understand that the present invention is further illustrated in connection with the specific embodiments.

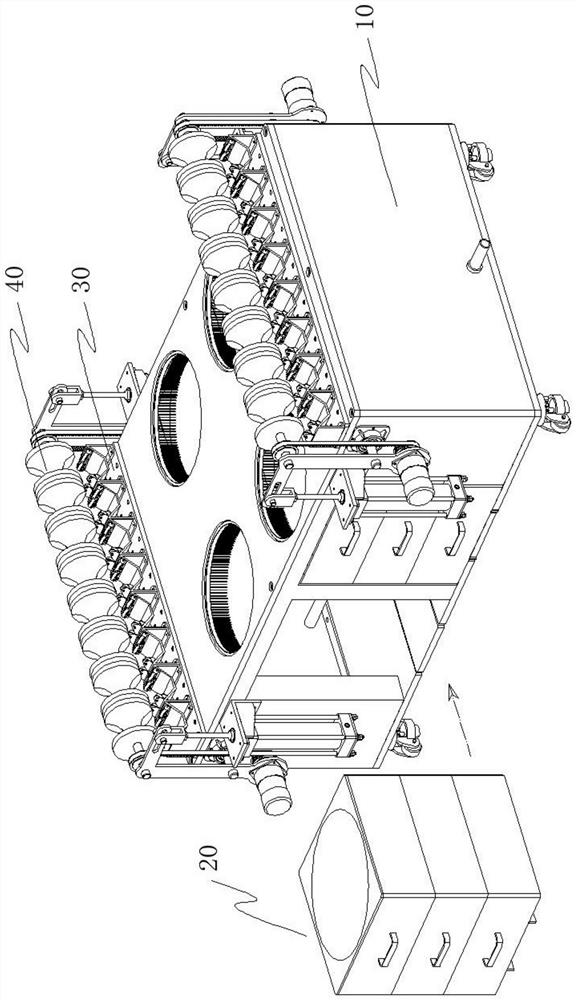

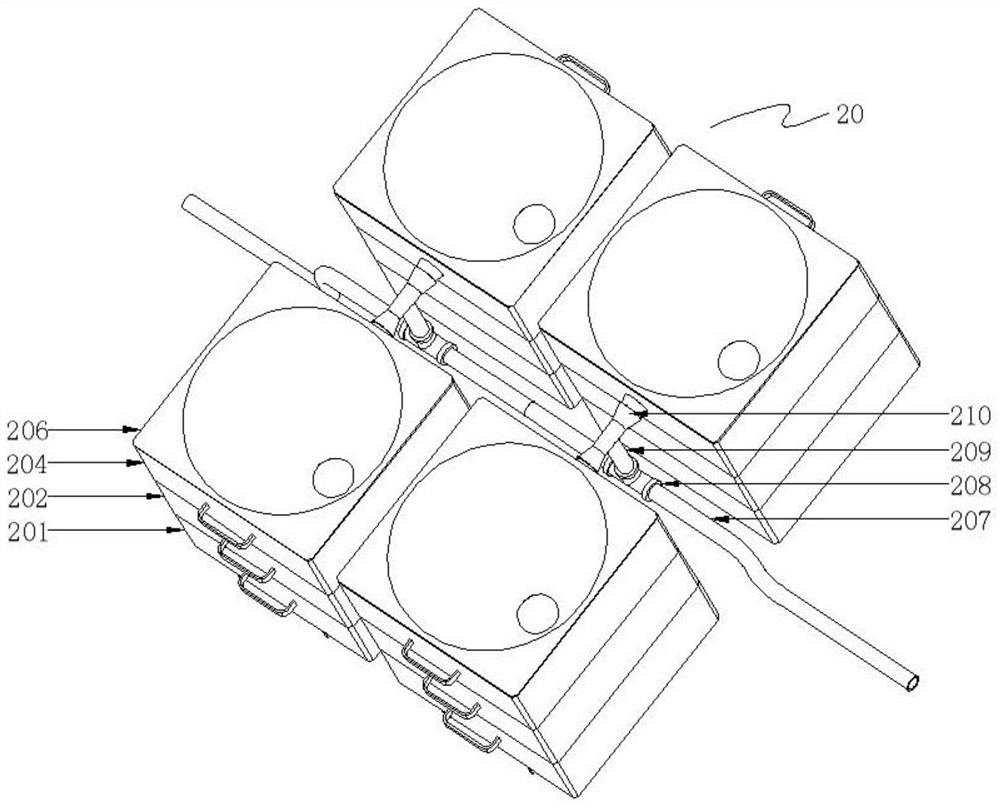

[0031] like Figure 1 to 8 As shown, a cutting platform of a glass steel article includes a support assembly 10, a chip assembly 20, a positioning assembly 30, and a clamping assembly 40, wherein:

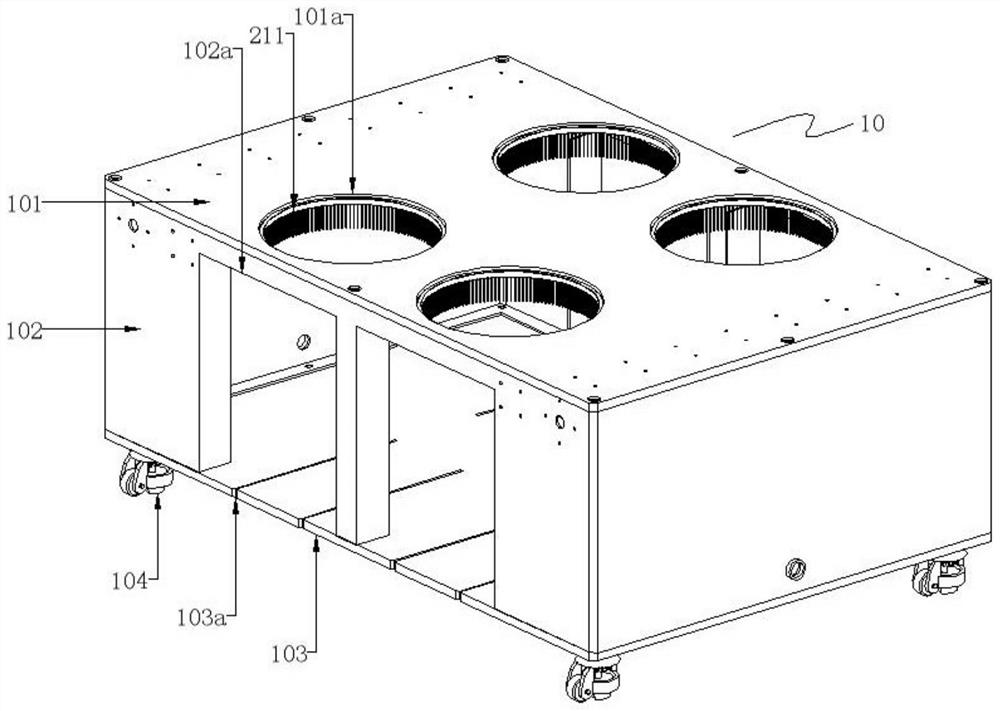

[0032] The support assembly 20 specifically includes a support top plate 101, a supporting cabinet 102, a supporting bottom plate 103, and a mutter 104, the support cabinet body 102 being a housing of a hollow long square structure without top and bottom surface, the support cabinet. The front and rear sides of the body 102 are provided with a uniformly spaced rectangular drawer port 102a, the support top plate 101, and the support bottom plate 103, respectively, at a top and bottom of the support cabinet 102, respectively, and the support top plate 101 is provided with a front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com