Automobile exhaust filtering silencer

A technology for automobile exhaust and muffler, applied in exhaust treatment, muffler device, exhaust device, etc., can solve the problems of increased cost of wearing parts, filter element without dust removal function, filter element blockage, etc., and achieves novel structure and instant The effect of detecting filtering status and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

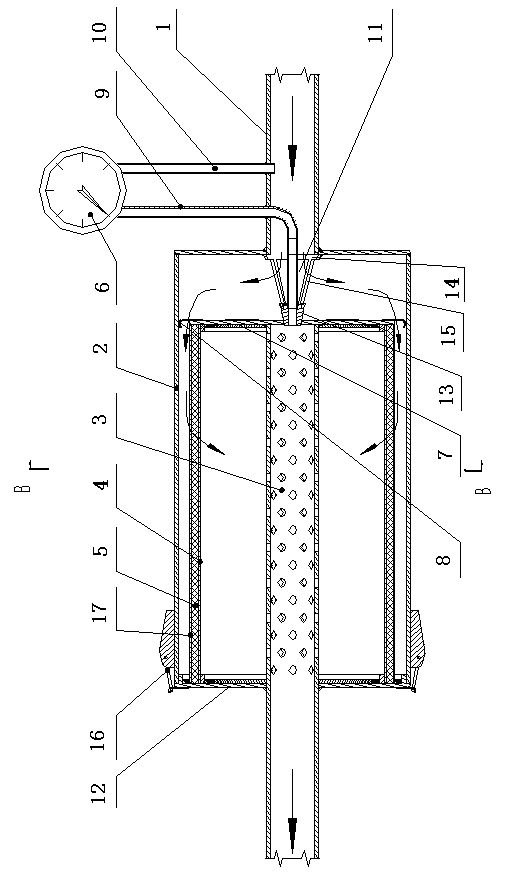

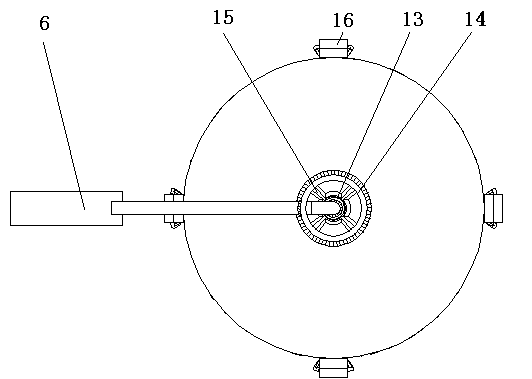

[0019] Below in conjunction with accompanying drawing, the present invention is further described:

[0020] As shown in the accompanying drawings, an automobile exhaust filter muffler is provided with an exhaust pipe 1, an outer cylinder body 2, and a core body pipe 3, and is characterized in that it is provided with a filter element skeleton 4, a filter element 5, a differential pressure gauge 6, an inner seal Cover 7, leaf spring 8, outer cavity pressure conduit 9, inner cavity pressure conduit 10, positioning plug 11 and outer sealing cover 12, the positioning plug 11 is in the shape of a truncated cone, and the positioning plug 11 is formed by a small conical ring body 13 It is connected with the large conical ring 14 through at least three connecting ribs 15 in a circular array. The center hole at one end of the outer cylinder 2 is fixedly connected with the outlet port of the exhaust pipe 1. The outer cylinder 1 is provided with a cylindrical Filter element frame 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com