Rubber hot press forming die

A hot press molding and mold technology, applied in the field of rubber molding, can solve the problems of molding needle position deviation, troublesome disassembly and replacement, friction loss between molding needle and mold, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

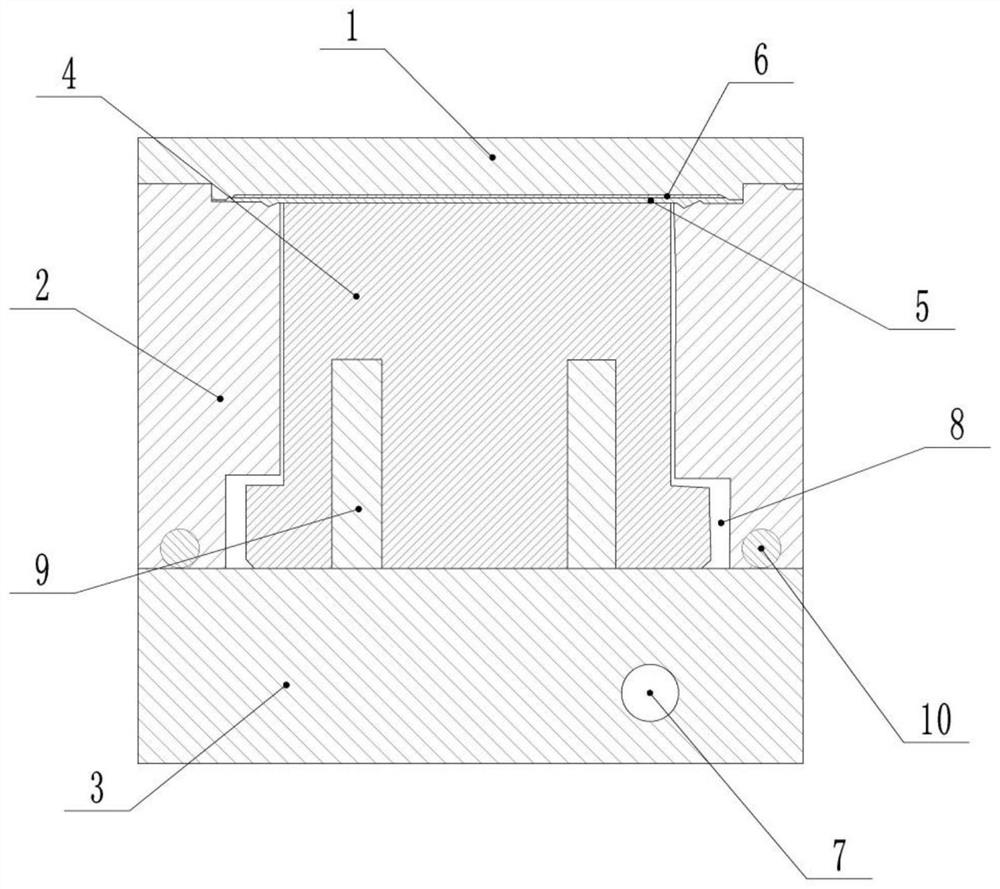

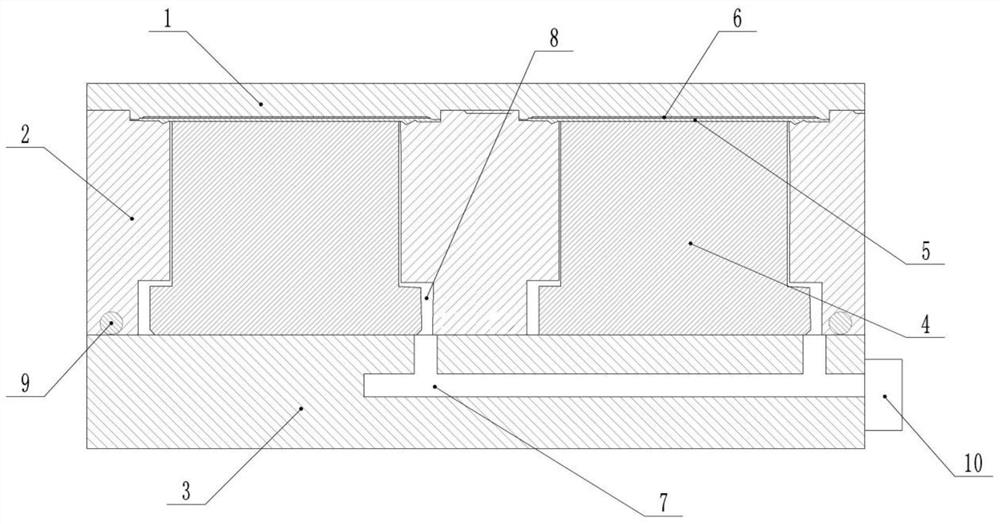

[0023] as attached figure 1 As shown, a mold for rubber thermocompression molding includes an upper mold 1, a middle mold 2, a cylindrical insert 4 and a lower mold 3, and guide grooves are provided at the edges of the upper mold 1, the middle mold 2 and the lower mold 3, Provides easy access to stacked molds and prevents confusion in mold orientation. The corresponding end of the upper mold 1 and the middle mold 2 is provided with an upper molding cavity, and the corresponding end of the middle mold 2 and the upper mold 1 is provided with a lower molding cavity. The positions of the lower molding cavity and the upper molding cavity are matched. Used together to make rubber products6. The number of upper molding cavities is 12, the number of lower molding cavities is 12, and the number of lower molding cavities corresponds to the number of upper molding cavities. It can complete the production of multiple rubber products at the same time, improving the production efficiency....

Embodiment 2

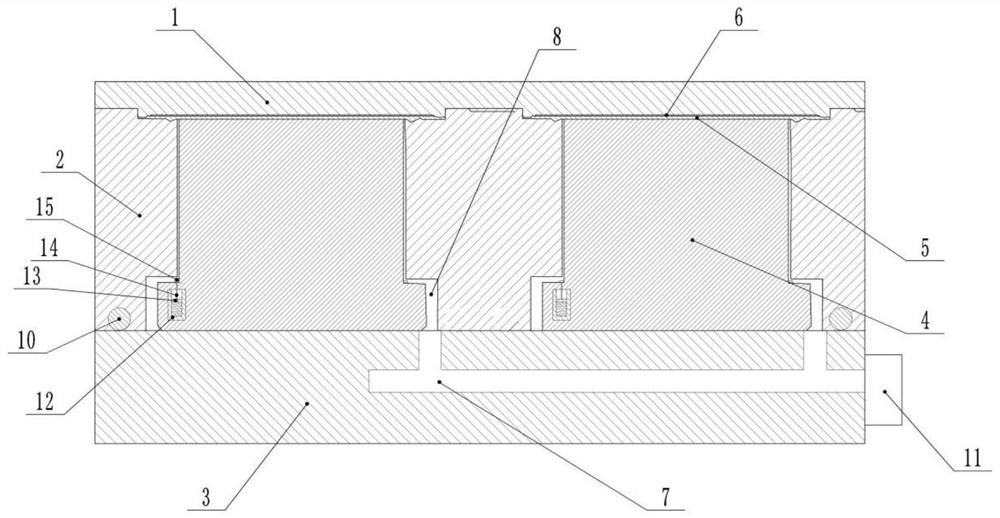

[0030] The difference between this embodiment and Embodiment 1 is that a negative pressure compensation mechanism is provided on the cylindrical insert 4, as shown in the attached image 3As shown, the negative pressure compensation mechanism includes a cylinder 12 and a sealing rubber ring 15, the cylinder 12 is fixedly connected with the cylindrical insert 4 through bolts, the cylinder 12 is located in the cylindrical insert 4, and the cylinder 12 is filled with a working medium, which is chloropropane , Chloropropane is a colorless liquid with the smell of chloroform, and the boiling point of chloropropane is 47°C. The cylinder 12 is provided with a piston 13, and a moving rod 14 is welded on the piston 13. The moving rod 14 is slidably arranged on the inner wall of the cylindrical insert 4. The moving rod 14 is welded to the cylinder 12 through a spring, and the spring can make the moving rod 14 recover quickly. In the original position, the moving rod 14 bolts are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com