Round spinning machine with dust removing device

A dust removal device and textile machine technology, applied to circular looms, textiles, looms, etc., can solve the problems of no dust removal, affecting yarn quality, reducing yarn aesthetics, etc., to achieve rapid dust removal and cleaning, improve safety, The effect of facilitating stable transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

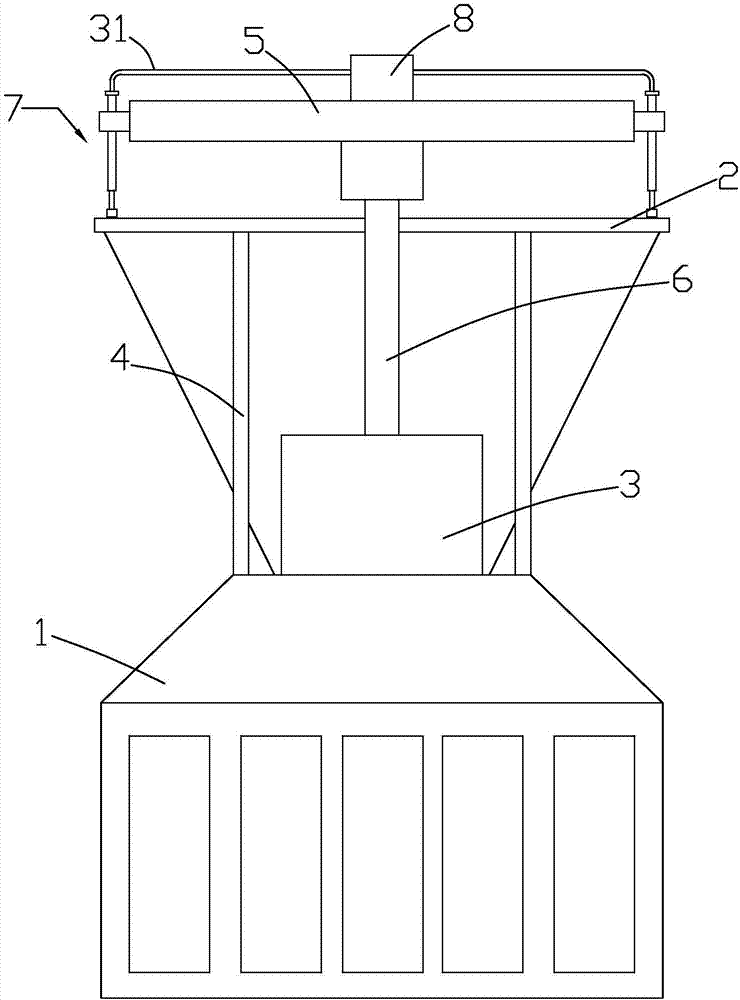

[0026] Such as Figure 1 to Figure 4 As shown, it is a circular textile machine with a dust removal device according to the present invention, which includes a machine body 1, a yarn guide 3 and a creel 2, the yarn guide 3 is fixedly connected to the top surface of the body 1, and the creel 2 is located Above the yarn carrier 3, the yarn carrier 2 is fixedly connected to the yarn guide 3 through the column 6, and the yarn carrier 2 is fixedly connected to the top of the machine body 1 through the support rod 4, which improves the stability of the yarn carrier 2 and facilitates the yarn to be rotated at the same time. Stable delivery.

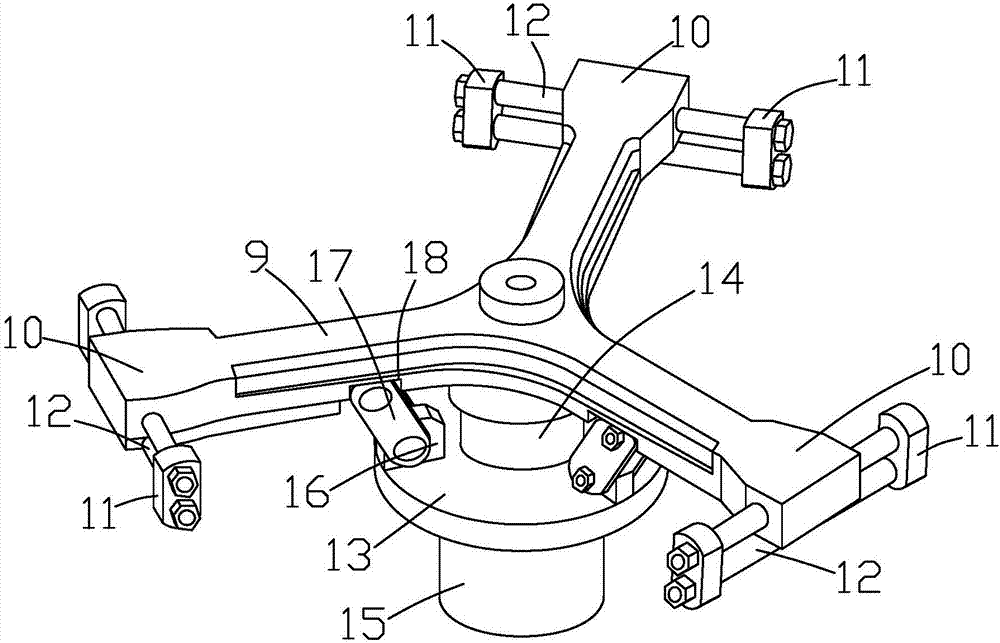

[0027] Above the creel 2 is provided with a rotating mechanism 5, a dust removal mechanism 7 and an air delivery device 8, the rotating mechanism 5 is connected to the column 6 in rotation, the rotating mechanism 5 includes a triangular bracket 9, and the ends of the triangular bracket 9 are provided with balance weights 10 The two sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com