Continuous cooling device for discharged plastic bags

A technology of cooling device and plastic bag, applied in the directions of transportation and packaging, separation method, separation of dispersed particles, etc., can solve the problems of uneven air outlet, poor cooling efficiency, inconvenient adjustment of inner diameter, etc., and achieve the effect of avoiding dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

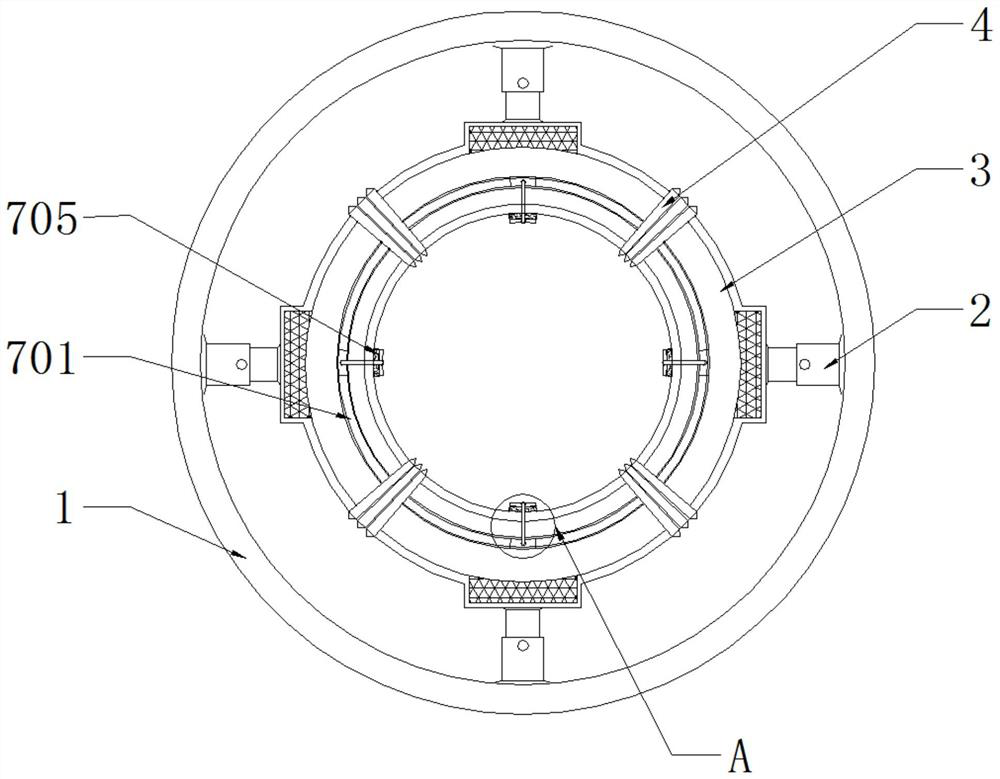

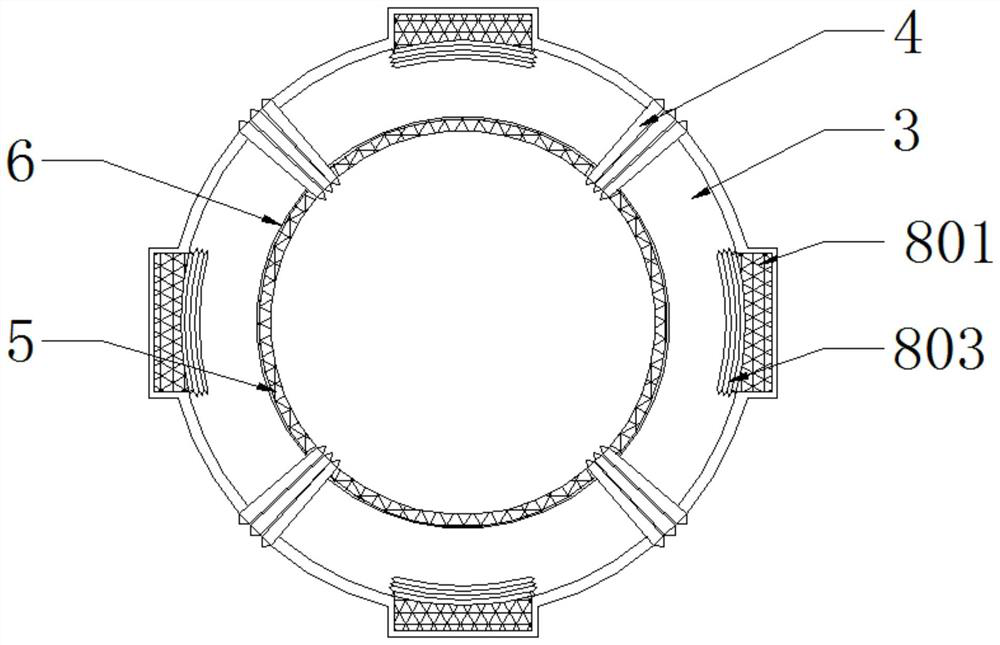

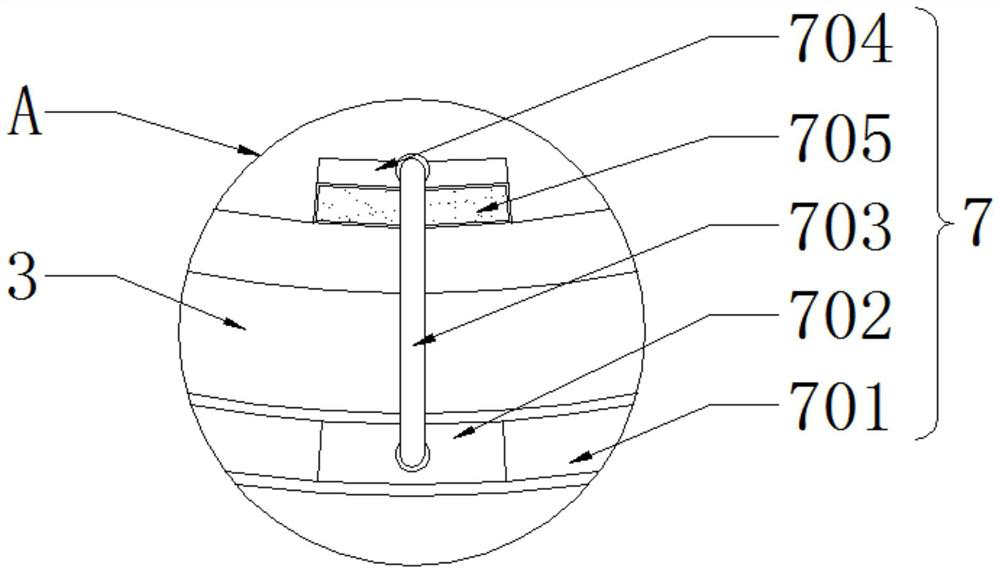

[0030] see Figure 1 to Figure 6 , the present invention provides a technical solution: a continuous cooling device for plastic bag discharge, including an outer ring 1, an inner ring pipe 3 and an air cooling assembly 8, a telescopic rod 2 is installed inside the outer ring 1, and the inner ring pipe 3 is fixed on a telescopic The top of the rod 2, and the outer corrugated pipe 4 is connected between the inner ring pipe 3, the inner side of the inner ring pipe 3 is provided with a vent 5, and the inside of the vent 5 is fixed with a filter screen 6, and the air cooling assembly 8 is placed inside The inner periphery of the ring pipe 3, and the air cooling assembly 8 includes an installation air chamber 801, a cooling fan 802, a corrugated sleeve 803, a ventilation pipe 804, an air outlet 805, a connecting flange 806 and an inner bellows 807, and the installation of the air chamber 801 A heat dissipation fan 802 is installed inside, and the inside of the installation air chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com