Fluctuation pressure adjusting system used for thread rib forming

A technology of pressure regulating system and threaded ribs, which is applied in the field of mechanical devices, can solve problems such as high production cost, large load, and low yield rate, and achieve the effects of reducing production cost, avoiding excessive load, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

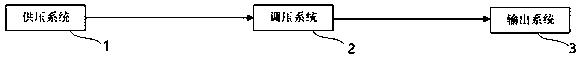

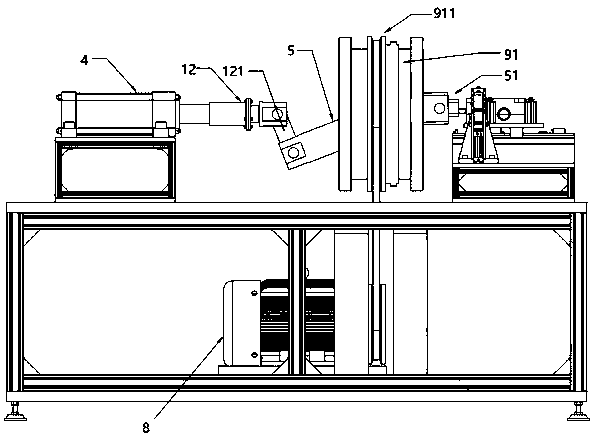

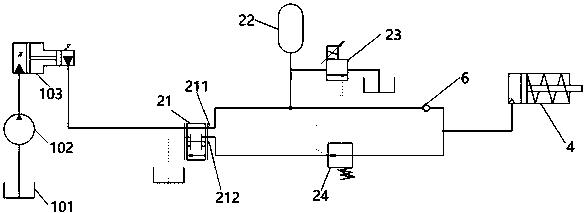

[0039] see Figure 1-8 As shown, a kind of wave pressure regulating system for threaded rib forming of the present invention comprises:

[0040] A wave propulsion system, the wave propulsion system includes a sequentially connected pressure supply system 1, a pressure regulation system 2, and an output system 3, the output system 3 includes a hydraulic cylinder 4, and the hydraulic cylinder 4 is transmission-connected to a tool holder 5, A cutter head assembly 51 is installed on the tool holder body 5, and an elastic member 7 against the cutter head assembly 51 is installed on the cutter holder body 5, and the elastic member 7 makes the output end of the cutter head assembly 51 have a Keep the initial position state of the inclination;

[0041] The wave propulsion system has a rapid pressurization stage and a wave loading stage, and controls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com