Heat preservation automatic quantitative feeding system for vacuum cold die casting

A feeding system and vacuum cooling technology, applied in casting equipment, mechanical cleaning, manufacturing tools, etc., can solve problems such as inability to accurately guarantee the production requirements of die castings, inability to accurately quantitatively feed materials, and poor molding effects of die castings, etc., to improve die casting production Efficiency, improvement of molding quality, and temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

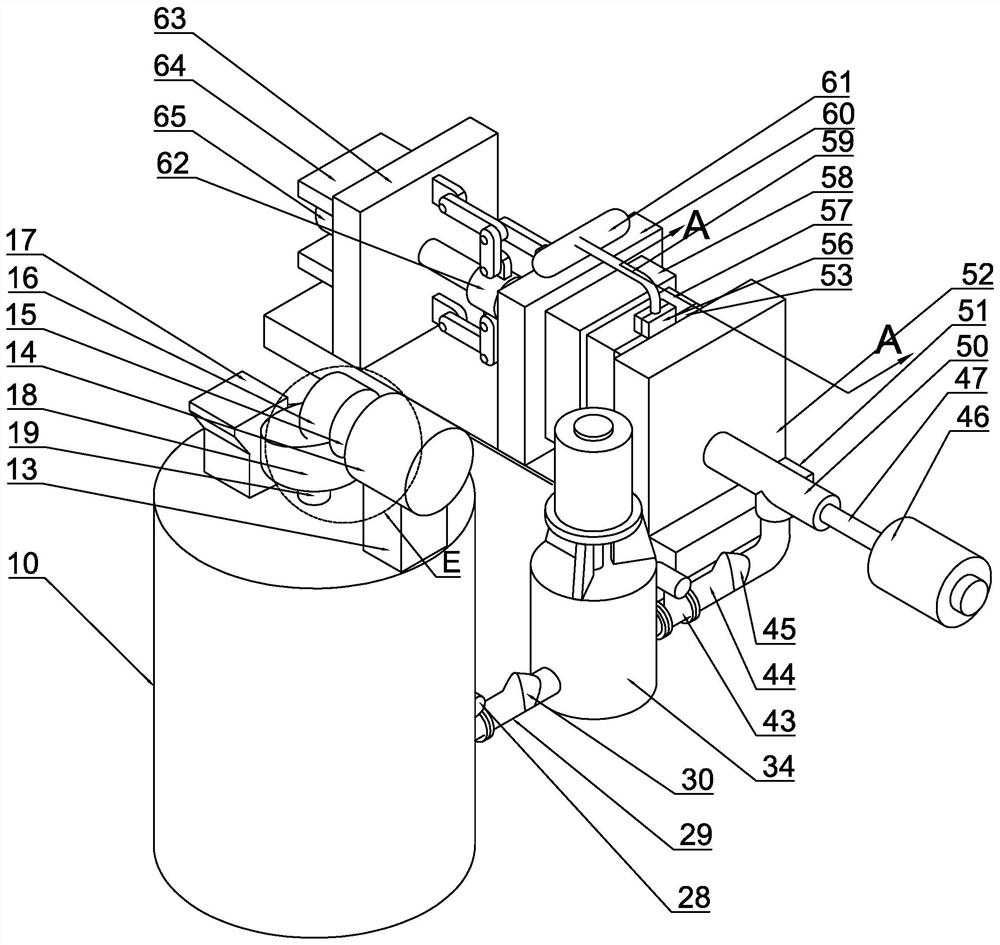

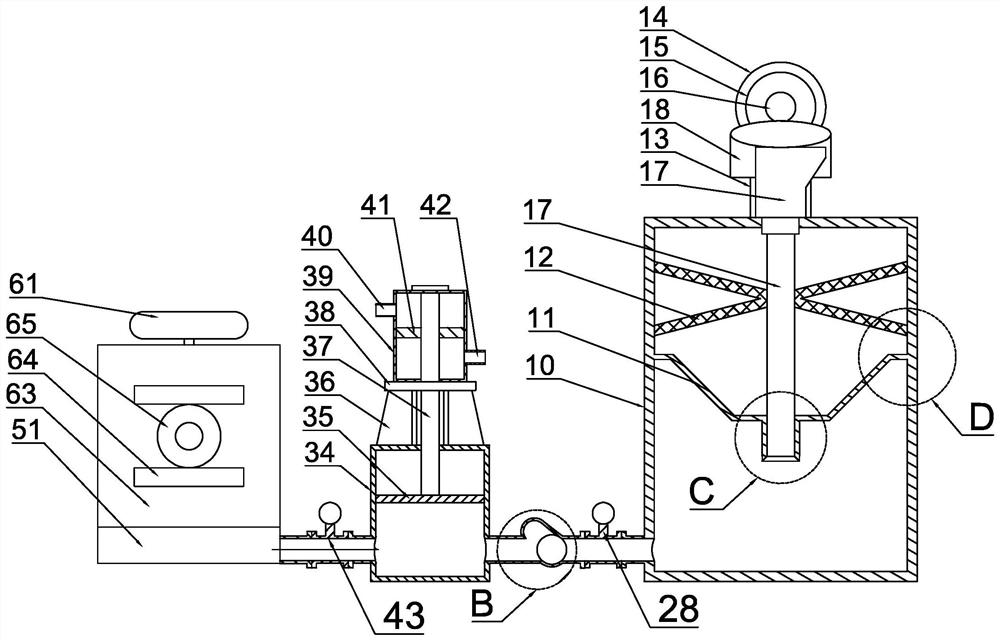

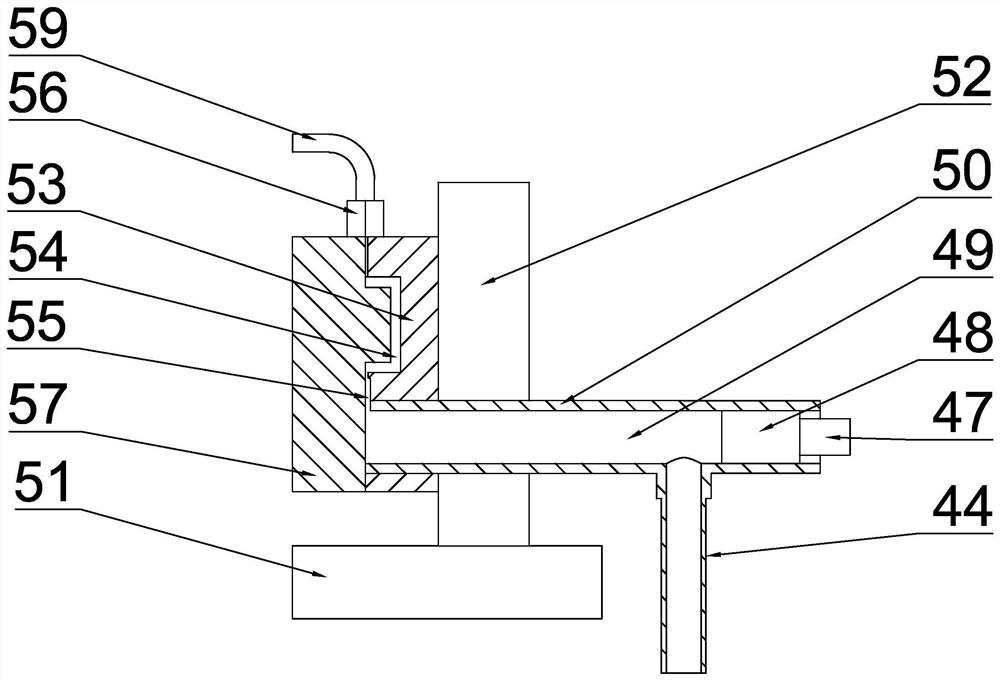

[0026] Such as figure 1 , figure 2 , Figure 5 and Figure 6 As shown, a thermal insulation automatic quantitative feeding system for vacuum cold die casting includes a heating insulation tank 10 fixedly arranged on the ground. Divide the inner cavity of the heating and insulating tank 10 into upper and lower cavities, the upper cavity of the heating and insulating tank 10 is an eddy current heating cavity 69, and the inner side wall of the eddy current heating cavity 69 is fixed with an eddy current heater 66 for Heating and melting the solid metal material, the lower chamber of the heating insulation tank 10 is a material storage insulation cavity 70, and the inner side wall of the storage material insulation cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com