Belt ply drum host and drive method thereof

A belt drum and main engine technology, applied in the field of rubber machinery manufacturing, can solve the problems affecting the uniformity of the composite layer structure of the belt material, the difficulty of precise control of the driving force, and the impact on the quality of tire building, etc., to achieve multi-point control It is beneficial to improve the synchronization mobility and ensure the uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

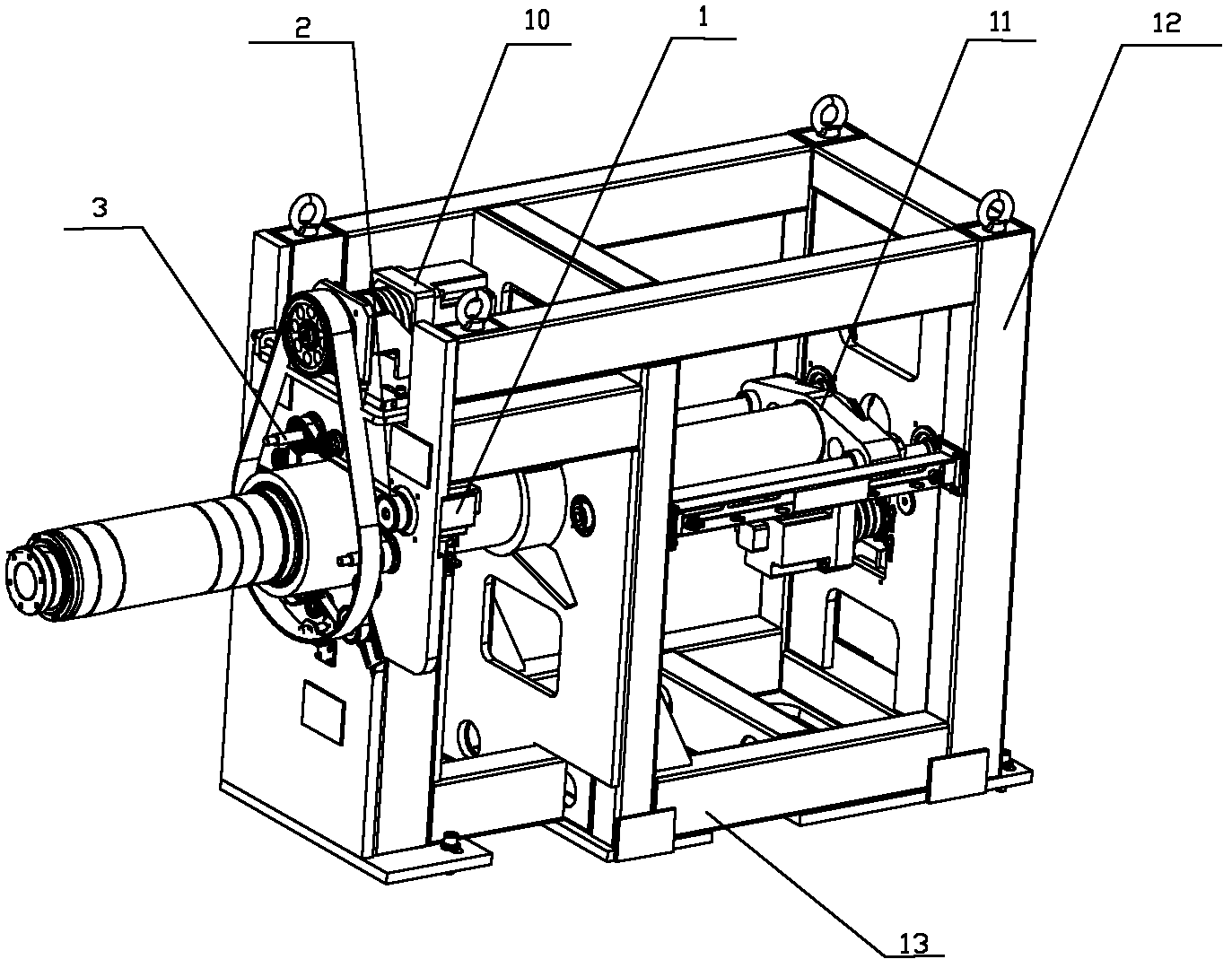

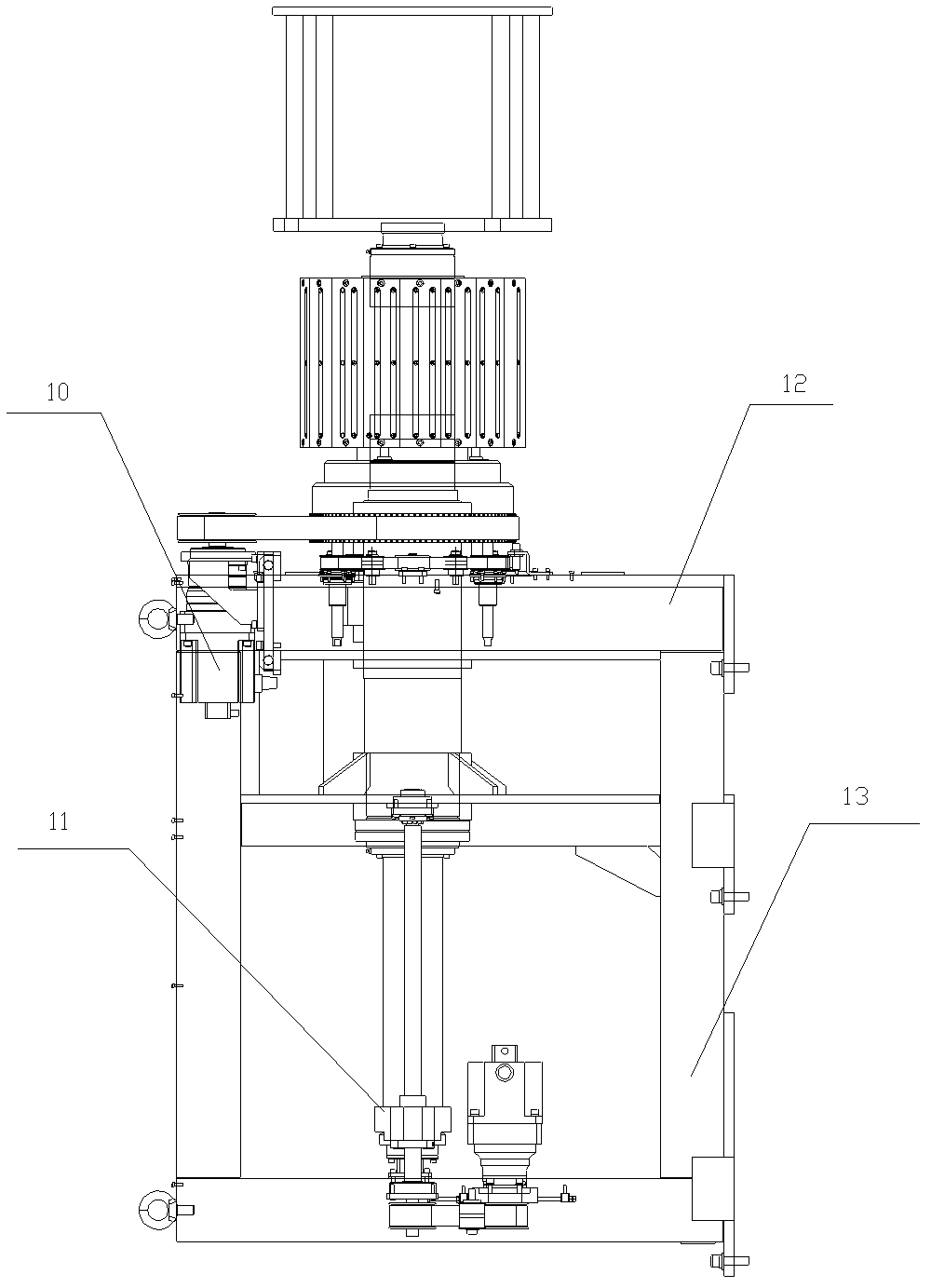

[0024] Example 1, such as Figure 1 to Figure 3 As shown, the belt drum main engine according to the present invention includes a box body 10 for radially moving the belt drum, a base 13 for fixedly linking on one end of the sliding track, and realizing the turn-up pressure synthesis of the tire blank. type booster mechanism 11, and the first drive mechanism 10 to realize the rotational movement of the belt drum axis.

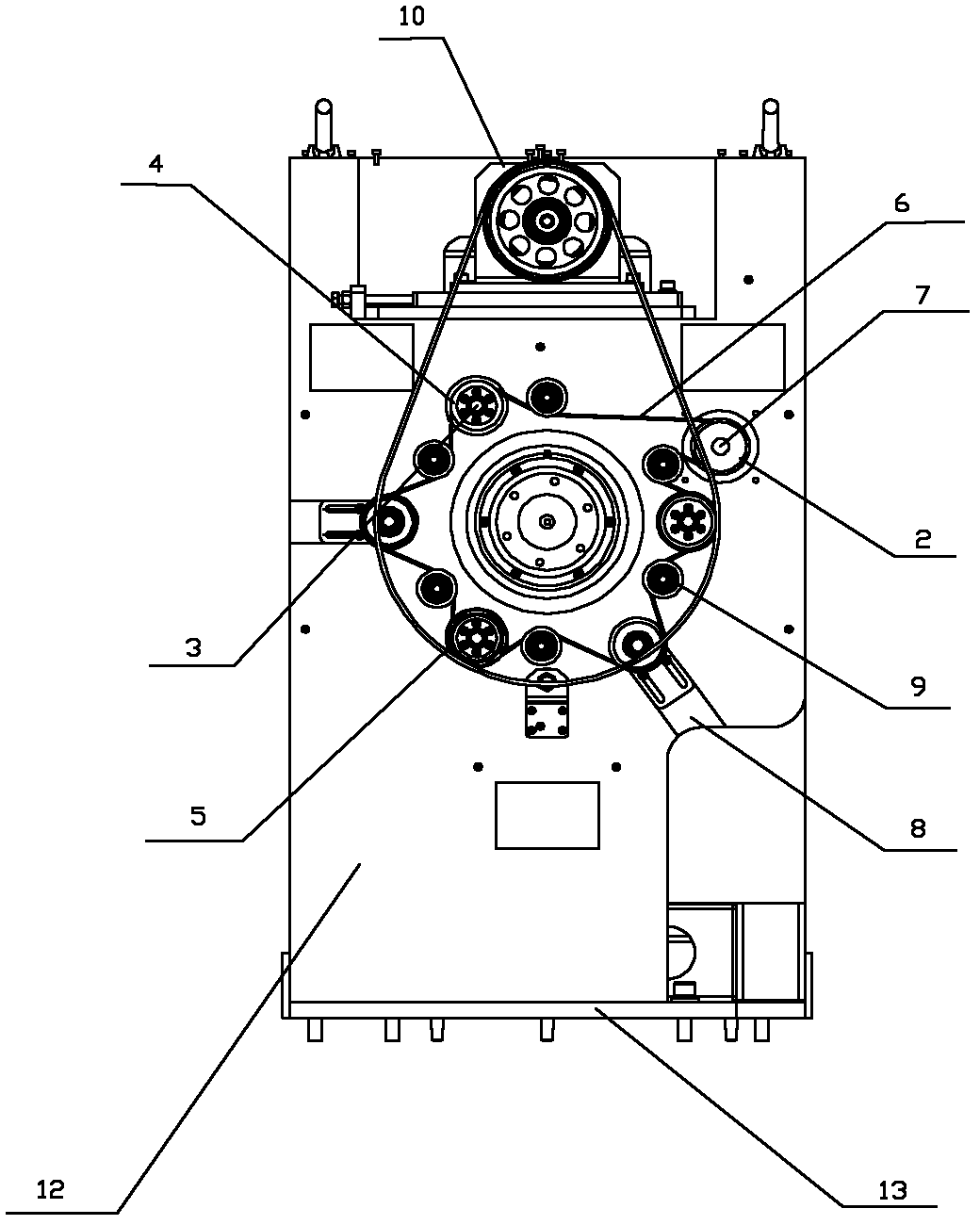

[0025] The left side of the belt drum main body casing 10 is provided with a second drive mechanism that provides power for the radial movement of the belt drum. The drive mechanism includes a drive motor 1, and the drive motor 1 is connected to a drive shaft 7. The drive motor 1 rotates synchronously, and drives the driving pulley 2 connected at the other end to rotate with a fixed axis.

[0026] There are also 3 synchronous assemblies on the left side of the main body of the belt drum, and each synchronous assembly includes a synchronous pulley 5, and tensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com