Compacting die for refractory brick

A technology for pressing molds and refractory bricks, which is applied in the field of pressing molds, and can solve the problems of insufficient height of annular ribs of refractory bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

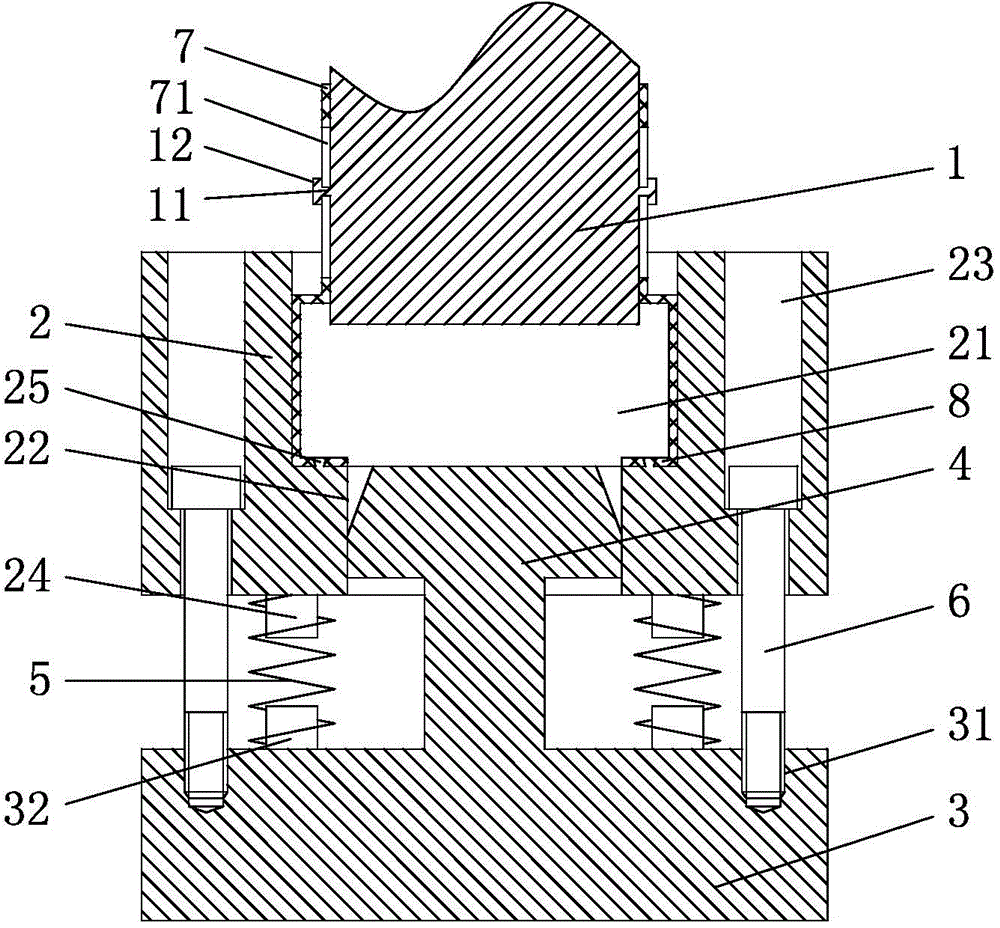

[0021] refer to figure 1 , a pressing die for refractory bricks, including a punch 1 and a die assembly, the die assembly includes a forming die 2, a fixing seat 3, a return spring 5 and a bolt 6, and the bolt 6 is threaded with the fixing seat 3 after passing through the forming die 2 Connected, the bottom end surface of forming mold 2 is provided with the first limiting block 24, and one end of return spring 5 is sleeved on the first limiting block 24 and touches the bottom end surface of forming mold 2, and the top end surface of fixing base 3 is provided with the second The limiting block 32 , the other end of the return spring 5 is sleeved on the second limiting block 32 and contacts the top surface of the fixing seat 3 .

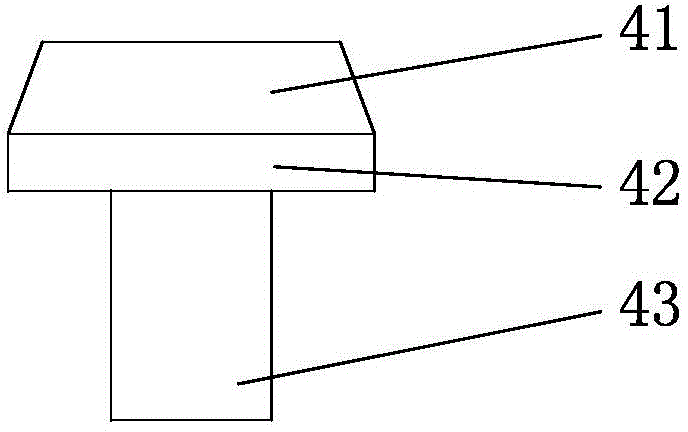

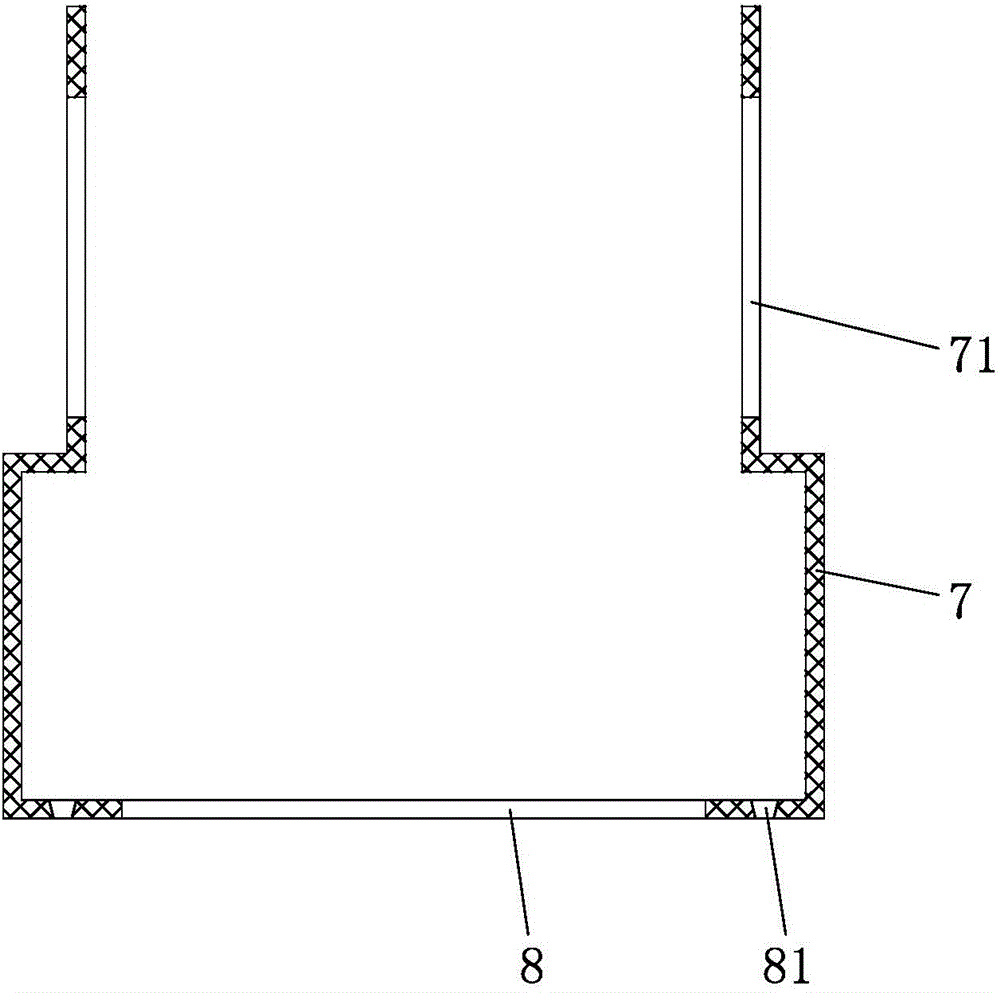

[0022] refer to figure 1 , figure 2 and image 3 , the forming die 2 is provided with a forming groove 21, the diameter of the punch 1 is 8mm smaller than the diameter of the forming groove 21, the bottom wall of the forming groove 21 is provided w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com