Gypsum built-in mould

A technology of built-in mold and gypsum, which is applied to building components, floors, buildings, etc., can solve the problems of increased damage rate of gypsum built-in mold, affecting the quality of concrete molding, and lack of waterproof ability, so as to simplify the construction process, reduce thickness, and waterproof powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A waterproof gypsum built-in mold, the mass percentage of raw materials is: gypsum powder: 55%, water: 44.4%, high-strength fiber: 0.3%, silicone waterproof powder: 0.3%. Wherein the high-strength fiber material is high-strength glass fiber or high-strength nylon fiber, and the fiber length is 2cm. After weighing according to the mass ratio, put it into a mixing bucket, stir for 2 to 5 minutes to fully mix the raw materials, and then pour it into a gypsum built-in mold for molding.

Embodiment 2

[0021] A waterproof gypsum built-in mold, the mass percentage of raw materials is: gypsum powder: 52%, water: 47.3%, high-strength fiber: 0.3%, silicone waterproof powder: 0.4%. Wherein the high-strength fiber material is high-strength glass fiber or high-strength nylon fiber, and the fiber length is 2cm. After weighing according to the mass ratio, put it into a mixing bucket, stir for 2 to 5 minutes to fully mix the raw materials, and then pour it into a gypsum built-in mold for molding.

Embodiment 3

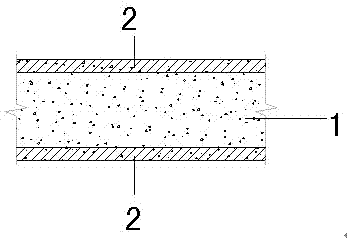

[0023] A waterproof gypsum built-in mold, the mass percentage of raw materials is: gypsum powder: 55%, water: 44.6%, high-strength fiber: 0.4%. Wherein the high-strength fiber material is high-strength glass fiber or high-strength nylon fiber, and the fiber length is 2cm. After weighing according to the mass ratio, put it into a mixing bucket, stir for 2 to 5 minutes to fully mix the raw materials, and then pour it into a gypsum built-in mold for molding. Such as figure 1 As shown, after the gypsum built-in mold 1 is dried, the outer surface of the built-in mold is sprayed with a silicone waterproof solution with a mass fraction of 0.3%, and finally the silicone waterproof layer 2 is formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com